- 36 -

www.NewLeader.com

(800) 363-1771

306375-AA-E

L5034G4 AGCO

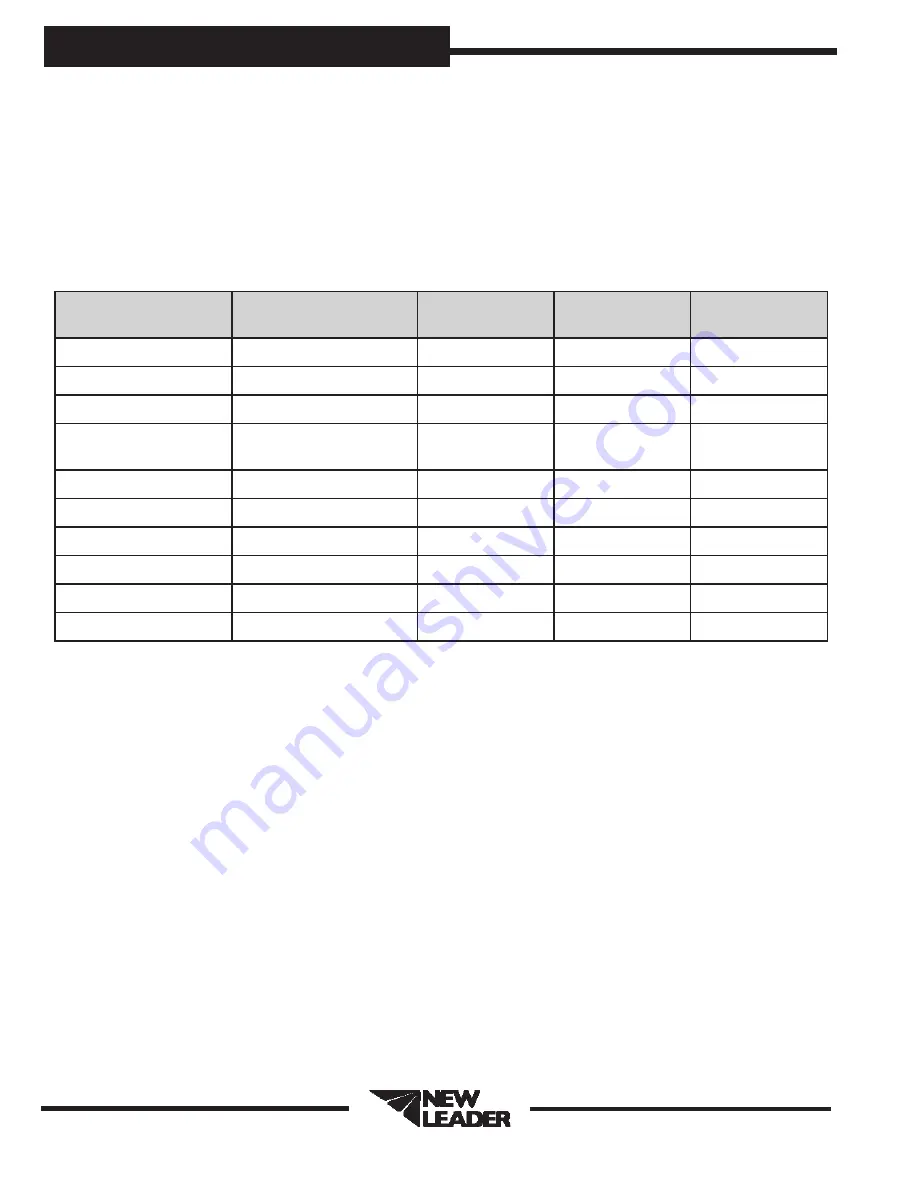

This chart is to help determine which conveyor is best for specific applications. Find the closest description

of the type of material to be spread�

• X indicates the preferred conveyor�

• O indicates a suitable alternative conveyor�

•

NR indicates the conveyor and/or spreader is not recommended for the specified application.

The density provided was used to make the conveyor recommendation� If the density of the material to

be spread is outside of those in the table, contact your New Leader dealer for the best conveyor for your

application�

Product

Density

lbs/ft³ (kg/m³)

#1 Chain

#2 Chain

#3 Chain*

Poultry Litter

16 - 54 (256 - 865)

X

O

O

Waste Sludge

40 - 65 (641 - 1041)

X

O

O

Paper Pulp

approx� 42 (673)

X

O

O

Compost Cattle Ma-

nure

36 - 65 (577 - 1041)

X

O

O

Gin Trash

35 - 50 (561 - 801)

NR

O

X

Fly Ash**

38 - 45 (609 - 769)

NR

X

O

Gypsum**

65 - 80 (1041 - 1281)

NR

NR

NR

Lime**

80 - 100 (1281 - 1602)

NR

NR

NR

Sulfur**

80 - 100 (1281 - 1602)

NR

NR

NR

Fertilizer

Not Recommended

NR

NR

NR

* - A #3 conveyor is not recommended for use with material that is greater than 25% moisture content� Wet

material can slip on a #3 conveyor and may not flow to the feed gate.

** - Trial and error is necessary to determine the spreader’s maximum capacity for each material so as not

to exceed the system pressures of the hydraulic system and stall the conveyor�

NOTE: Field experience has shown that payload capacity can be increased with the use of chain shields in

some applications�

Conveyor Selection