© New Scale Technologies, Inc. MPM System Manual, June 9, 2017

P a g e

|

5

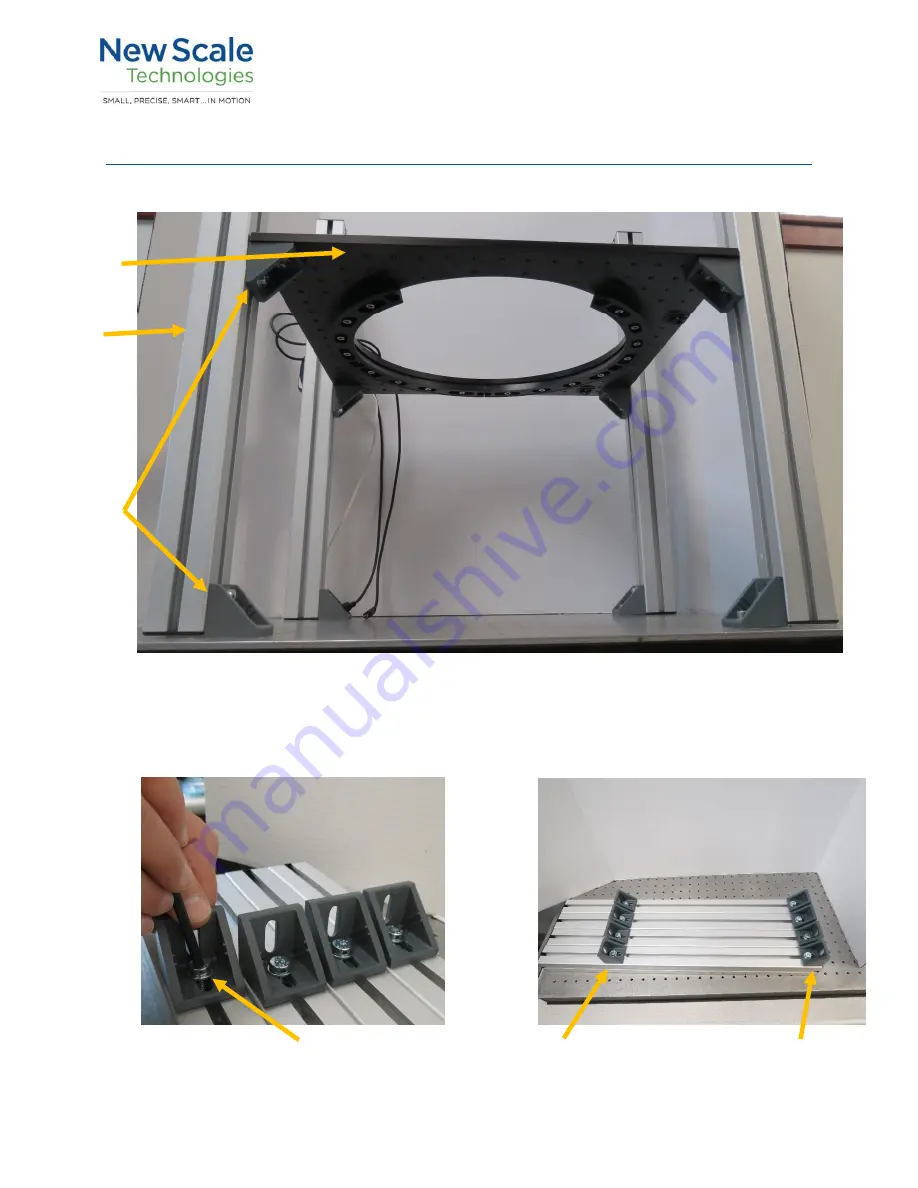

MPM-Platform

The

MPM-Platform

is designed to be compatible with

MPM-Ring-72 Deg

sections.

1.

Adjust the position of the angles so (4) are the desired height and (4) are at the end, using the

provided wrench.

MPM-Platform

assembled with (4)

MPM-Ring-72 Deg

sections installed

Platform

Legs

Angles

Loosen/tighten to adjust position

(4) angles at desired height

(4) angles at end