26

110839-01 - 8/20

AP-U

Installation & Service Manual

iii.

Limited Recycle:

This feature limits the

number of recycle trials (for each call

for heat) to a maximum of three trials. If

the flame is lost three times and does

not successfully satisfy a call for heat,

the 7505 locks out.

iv.

Limited Reset (Restricted Mode):

In

order to limit the accumulation of

unburned oil in the combustion area,

the control can only be reset three

times. The reset count returns to zero

each time a call for heat is successfully

completed.

v.

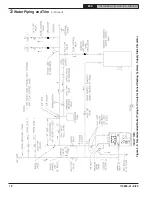

T-T Jumper: Select models have

pre-installed T-T jumper.

DO NOT

remove jumper.

Note:

DO NOT

remove “T-T” jumper

unless

wiring diagram indicates a direct

connection from thermostat and/or

tankless heater aquastat control to the

oil burner primary control’s “T-T”

terminal. Refer to appropriate wiring

diagram, see Figure 5-1.

vi.

Diagnostic LED: The indicator light on

oil primary control provides lockout,

recycle and cad cell indications as

follows:

•

Flashing at 1 Hz (½ second on, ½

second off): system is locked out or

in Restricted Mode.

•

Flashing at ¼ Hz (2 seconds on, 2

seconds off): control is in Recycle

Mode.

•

On: cad cell is sensing flame.

•

Off: cad cell is not sensing flame.

vii.

Cad Cell Resistance Check

:

For proper

operation it is important that the cad

cell resistance is below 1600 ohms.

During a normal call for heat, the cad

cell leads can be unplugged from the

control and the resistance measured

with a meter in the conventional way.

Conduct these tests with flame present,

see chart below.

Flame Detection Range

Normal (0 - 1600 ohms)

Limited (1600 ohms to lockout)

3. CHECK OIL PRIMARY CONTROL

CAUTION

Due to the potential hazard of line voltage,

only a trained, experienced service technician

should perform the following safety checks.

This control contains no field-serviceable parts.

DO NOT attempt to take it apart. Replace entire

control if operation is not as described.

a.

Preliminary Steps

•

Check wiring connections and power

supply.

•

Make sure power is on to the controls.

•

Make sure limit control is closed.

•

Check contacts between ignitor and the

electrodes.

•

Check the oil pump pressure.

•

Check the piping to the oil tank.

•

Check the oil nozzle, oil supply and oil

filter.

b. Check Safety Features

Safe Start:

•

Place a jumper across cad cell terminals.

•

Follow procedure to turn on burner.

Burner must not start, indicator light turns

on and control remains in Idle Mode.

•

Remove jumper.

c. Simulate Ignition or Flame Failure:

•

Follow procedure to turn on burner.

•

Check cad cell resistance. If resistance

is below 1600 OHMS and burner runs

beyond safety cut-out time, cad cell is

good.

•

If safety switch shuts down burner and

resistance is above 1600 OHMS, open

line switch to boiler. Access cad cell

under ignitor, clean face of cad cell and

see that cell is securely in socket. Check

gasket around perimeter of ignitor lid for

proper seal. If gasket is missing or

damaged, replace gasket.

Room light can effect cad cell

resistance. Reset safety switch.

•

Close line switch to boiler. If burner

starts and runs beyond safety switch

cut-off time, cell is good. If not, install

new cell.

•

Close hand valve in oil supply line.

7

System Start-Up

(continued)

!

Summary of Contents for AP-U AP-110U-N

Page 41: ...41 110839 01 8 20 AP U Installation Service Manual This page intentionally left blank...

Page 46: ...46 110839 01 8 20 AP U Installation Service Manual SERVICE RECORD SERVICE PERFORMED DATE...

Page 47: ...47 110839 01 8 20 AP U Installation Service Manual SERVICE RECORD SERVICE PERFORMED DATE...

Page 48: ...48 110839 01 8 20 AP U Installation Service Manual...