24

X. Troubleshooting

A.

BEFORE TROUBLESHOOTING

The following pages contain troubleshooting tables for

use in diagnosing control problems. When using these

tables the following should be kept in mind:

1. This information is only meant to be used by

a professional heating technician as an aid in

diagnosing boiler problems.

2. In general, these tables assume that there are no

loose or miswired electrical connections. Before

using these tables inspect all electrical connections

on the boiler to make sure that they are tight. Also,

check the wiring on the boiler against the wiring

diagram in Figures 9 and 10. Ensure that incoming

120 Vac power polarity is correct and that the boiler

is properly grounded. Further, ensure that the control

power supply is 24 VAC (minimum 18 VAC to

maximum 30 VAC) and polarity is correct.

4. All controls on the CG-E Series are tested at least

once in the manufacturing process and a defective

control or component is generally the least likely

cause. Before replacing a component, try to rule out

all other possible causes.

5. When checking voltage across wiring harness pins

be careful not to insert the meter probes into the

pins. Doing so may damage the pin, resulting in a

loose connection when the harness is reconnected.

Table 3: Troubleshooting Using the Control's LED

Flashing LED

Fault Condition

POWER

Steady 1 Hz flash

Flash code 2

Flash code 3

Flash code 4

Flash code 5

Flash code 6

Reverse polarity of 115 VAC supply voltage

Faults internal to microprocessor (RAM, ROM, etc.)

Unused

Unused

Water thermistors disagree

Gas valve outputs in improper state

POWER + TSTAT/CIRC

48 volts on Thermostat circuit

DAMPER

Damper switch opened after it had been proved closed. Continues flashing until demand for heat

removed or Damper switch proven closed in ignition sequence.

POWER + DAMPER

Damper switch stuck open or closed (control in damper switch lockout)

LIMIT

Fault detected in temperature sensing hardware

FLAME

Flame loss, or flame not sensed during trial for ignition. Continues flashing until either flame is

established or demand for heat is removed.

POWER + FLAME

Flame sensed without call for heat or out of sequence during ignition trial.

Lockouts

1. Lockout from internal hardware faults (listed above under POWER) automatically resets after the hardware fault has

not been present for 60 minutes. Lockouts from internal hardware faults may not be manually reset except by removing

power from the control.

2. Lockout from damper switch failing to close within 45 seconds automatically resets after 60 minutes. Lockout may be

manually reset by opening the thermostat for more than 2 but less then 20 seconds.

Summary of Contents for CG-E SERIES

Page 4: ...4 Figure 1 Minimum Clearance to Combustible Materials and Alcove Dimensions...

Page 8: ...8 Figure 5 Recommended Water Piping for Zone Valve Zoned Heating Systems...

Page 9: ...9 Figure 6 Recommended Water Piping for Circulator Zoned Heating Systems...

Page 14: ...14 Figure 9 Wiring Connection Diagram...

Page 15: ...15 Figure 10 Schematic Ladder Diagram...

Page 16: ...16 Figure 11 Wiring Schematic Zone Valves Figure 12 Wiring Schematic Zone Circulators...

Page 18: ...18 Figure 14 Operating Instructions...

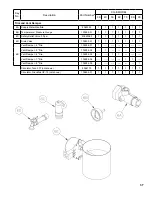

Page 31: ...31 Section Assembly and Canopy Group...

Page 38: ...38...

Page 39: ...39...

Page 40: ...40...