11

VII Venting

A. General Vent System Design

There are three basic ways to vent this boiler:

•

Horizontal (“Side Wall”) Twin Pipe Venting (Figure 7.0a)

- Vent system exits the building through an outside wall.

Combustion air and flue gas are routed between the boiler and the terminal(s) using separate pipes. A summary of

Horizontal Twin Pipe venting options is shown in Table 7.5.

•

Vertical Twin Pipe Venting (Figure 7.0b)

- Vent system exits the building through a roof. Combustion air and flue gas

are routed between the boiler and the terminal(s) using separate pipes. A summary of Vertical Twin Pipe venting options

is shown in Table 7.11

•

Split Venting (Figure 7.0c)

- Exhaust system exits the building through a roof, and combustion air is drawn from a

terminal mounted on the side wall. A summary of split venting options is shown in Table 7.15

WARNING

• Asphyxiation Hazard. Failure to vent this boiler in accordance with these instructions could cause

products of combustion to enter the building resulting in severe property damage, personal injury

or death.

• Do not interchange vent systems or materials unless otherwise specified.

• The use of thermal insulation covering vent pipe and fittings is prohibited.

• Do not use a barometric damper, draft hood or vent damper with this boiler.

• When using the CPVC/PVC vent option, the use of CPVC is required when venting in vertical or

horizontal chase ways.

• Any CPVC vent materials supplied with this boiler do not comply with B149.1.S1-07 and are not

approved for use in Canadian jurisdictions that require vent systems be listed to ULC S636-2008. In

these jurisdictions, vent this boiler using a listed ULC S636 Class IIB venting system.

• Do not locate vent termination where exposed to prevailing winds. Moisture and ice may form on

surface around vent termination. To prevent deterioration, surface must be in good repair (sealed,

painted, etc.).

• Do not locate air intake termination where chlorines, chlorofluorocarbons (CFC’s), petroleum

distillates, detergents, volatile vapors or other chemicals are present. Severe boiler corrosion and

failure will result.

• The use of cellular core PVC (ASTM F891), cellular core CPVC or Radel (polyphenolsulfone) is

prohibited.

• Do not locate vent termination under a deck.

• Do not reduce specified diameters of vent and combustion air piping.

• Do not allow low spots in the vent where condensate may pool.

NOTICE

This manual covers installation of vent options employing CPVC/PVC vent systems only. Other vent

options exist for this boiler which use listed polypropylene (PP) vent systems offered by several

manufacturers. Supplemental instructions for the design and installation of these vent systems with

this boiler are available on our web site.

Summary of Contents for GHE Series

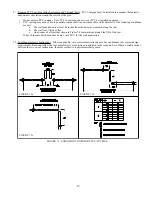

Page 10: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

Page 11: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Page 17: ...16 FIGURE 7 4 WALL PENETRATION CLEARANCES FOR PVC VENT PIPE...

Page 34: ...33 FIGURE 7 24 INSTALLATION OF IPEX AND DIVERSITECH CONCENTRIC TERMINAL THROUGH ROOF...

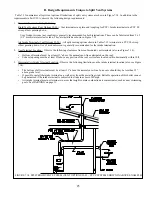

Page 41: ...40 FIGURE 9 2 NEAR BOILER PIPING HEATING ONLY BOILER LOOP PIPING SHOWN SHADED...

Page 42: ...41 FIGURE 9 3a NEAR BOILER PIPING HEATING PLUS INDIRECT WATER HEATER...

Page 43: ...42 FIGURE 9 3b NEAR BOILER PIPING HEATING PLUS INDIRECT WATER HEATER...

Page 47: ...46 This page is intentionally left blank...

Page 50: ...49 FIGURE 10 2 LINE VOLTAGE FIELD CONNECTIONS FIGURE 10 3 LOW VOLTAGE PCB TERMINAL CONNECTIONS...

Page 52: ...51 FIGURE 10 4a 120V LWCO FIELD WIRING FIGURE 10 4b 24V LWCO FIELD WIRING...

Page 54: ...53 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Page 55: ...54...

Page 62: ...61 Lighting and Operating Instructions...

Page 82: ...81 FIGURE 14 6 CONTROLS LOCATION FIGURE 14 7 PRESSURE SWITCH TUBING CONNECTIONS...

Page 87: ...86 Blower Gas Valve Assembly for 150 180...

Page 90: ...89...

Page 103: ...102...