Setting Up The Unit

Error Compensation Setup

19

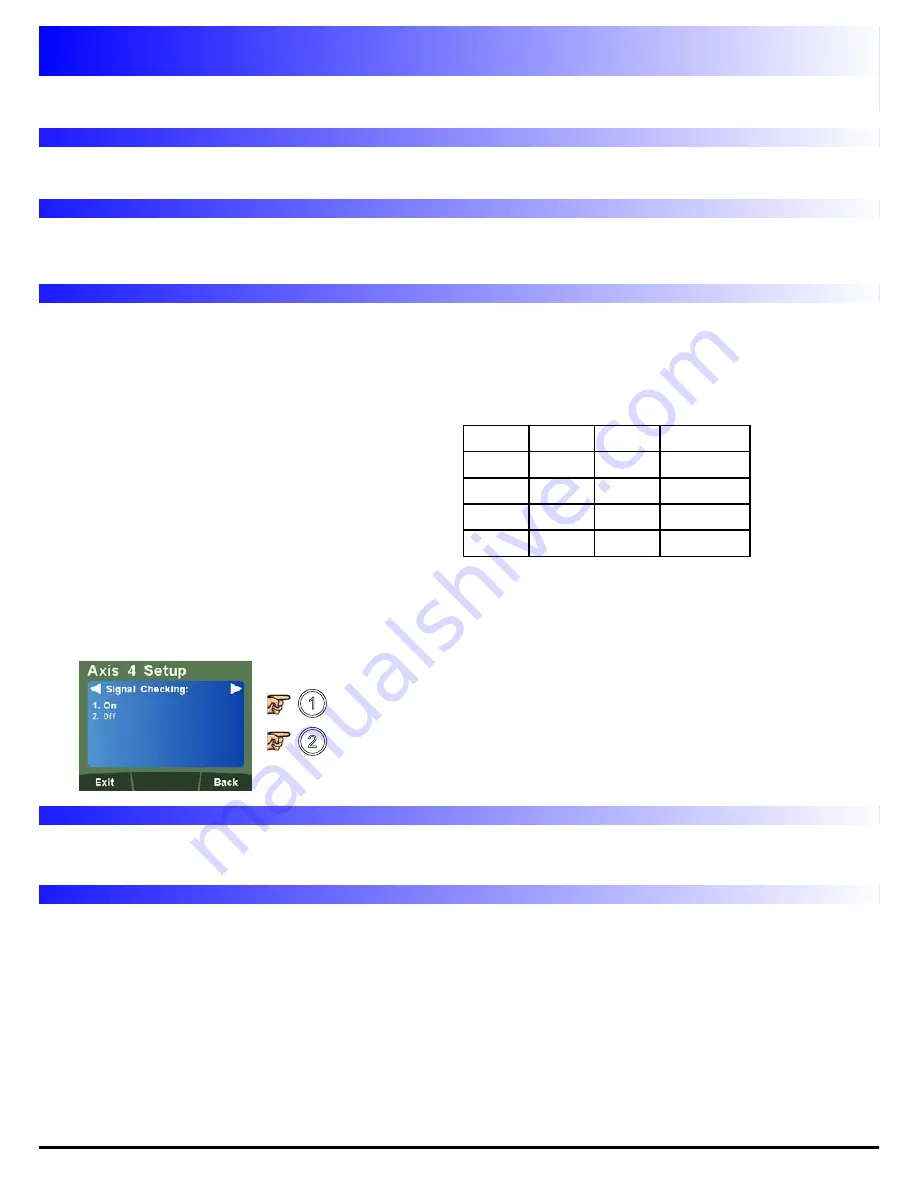

Signal Checking Setup

The DP1200 has the facility to detect if the encoder attached to the 4th digital axis has become

disconnected, sustained severe cable damage, or with some encoders, experienced electronic failure.

To enable Signal Checking

To disable Signal Checking

Zero Approach Setup

Please refer to Page 11, Zero Approach Setup

Please refer to Page 11, Error Compensation Explanation

Page 12, Type of Machine Error

Page 12, Linear Error Compensation Explanation

Page 13, Linear Compensation Setup

Direction Setup

Please refer to Page 10, Direction Setup

Radius / Diameter (Measure Setup)

Please refer to Page 10, Radius / Diameter (Measure Setup)

Mode of Operation

The detection mechanism monitors the incoming signals from the encoder to look for an illegal

combination of input levels.

If the encoder becomes disconnected, then the illegal

input combination is generated internally within the

DP1200. The display will then show ‘SIG FAIL’. If it is

possible to correct the fault, press the axis zero key to

reset that display. If the ‘SIG FAIL’ message continues

to be displayed then the fault has not been corrected.

A

B

RM

Status

L

L

H

SIG FAIL

L

H

X

OK

H

L

X

OK

X

X

L

OK

X = any state i.e can be either high (H) or low (L).

Note:

Please check the encoder specification for information on the synchronisation of the index

marker pulse. If the encoder is capable of generating the illegal condition (A low, B low and RM high),

then signal checking function should be

TURNED OFF

.

Summary of Contents for dp1200

Page 1: ...User Manual DP1200 Digital Readout...

Page 2: ......