14

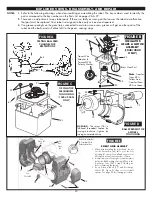

LEVELING ADJUSTMENT (2040+ ONLY)

Robo-Pong 2040+ is designed to sit level when attached to

the table. In proper position (Figure 16), the CT Support

Legs fit underneath the table and the CT Front Support

Plate sits on top of the table. If the robot does not sit level,

balls will not feed properly. If this condition occurs, it is

necessary to make some leveling adjustments. The first

adjustment is to level the table top by placing shims under

the table legs until the table top is level.

If this does not cause the robot to sit level, then it will

be necessary to make adjustments to the robot itself. The

Support Legs come with 3 sizes of Rubber Tips and 4 rub-

ber spacer-washers to accommodate different table top

thicknesses, and cause the Center Trough to sit level. The

Rubber Tips are marked on their top with the table thick-

ness they are used with. The longest is used for

1/

2

″

tops.

The mid-size one is used on

3/

4

″

tops and comes pre-

installed. The shortest tip is used for 1

″

tops.

In addition to these different sized tips, there are 4 rub-

ber spacer-washers which are used with the Rubber Tips

for finer adjustments. Either one or two of these spacer-

washers (depending on how much adjustment you need)

are placed inside the Rubber Tips before the tips are placed

on the end of the Support Legs.

Another reason why your robot may not sit level is that

it is not properly seated on the locating tab. When seated

correctly, the Support Flange of the Back Panel sits flush on

the Locating Tab that protrudes from the top of the Center

Trough (see Figure 17). Your robot serial number is located

on top of this Support Flange.

Tip: If it is possible to adjust the level of the robot’s half

of the table independently from the player’s half, you may

choose to purposely give a slight slope to the robot’s half so

balls that end up on the table roll into the robot’s trays. If

you make the table unlevel, make sure the robot sits level

by adjusting the Rubber Tips as described above. In this

case, it may be necessary to use the Rubber Tip one size

larger than normal to level the robot.

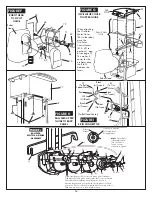

ADJUSTING NET TENSION (2040+ ONLY)

The Ball Return Trays should sit level with or just below the level of

your table top. If the tension of the Main Net is too tight, the trays

will be pulled up into a slight “V” shape with the top edge of the

trays above the level of the table top. To correct this situation, you

can loosen the adjustment straps shown in Figure 18 until the trays

sit level. If this adjustment is insufficient, stretch the net by grab-

bing it with two hands and pulling gently apart.

The Trap Net (the black net with large holes) slows down your

returns so more of them are captured. The size of the holes is slight-

ly smaller than the diameter of a ball. Hard hit shots force the ball

through the net and the ball becomes trapped between the Trap Net

and the Main Net. When slowly hit balls contact the Trap Net, they

do not have enough force to go through the net, so they immediate-

ly drop down into the trays.

The Trap Net is normally hung loosely so as to increase its

energy-absorbing capability. If you are practicing hard hit shots like

smashes or fast loops, you may find that a tighter Trap Net cap-

tures more of your shots. The tension of the Trap Net is adjusted by

tightening or loosening the velcro straps at the sides of the Trap Net

(see Figure 19).

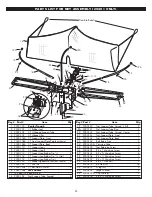

MISCELLANEOUS ADJUSTMENTS (2040+ ONLY)

CENTER TROUGH ATTACHMENT

(2040+ ONLY)

FIGURE 16

ADJUSTING MAIN NET TENSION

(2040+ ONLY)

FIGURE 18

ADJUSTING TRAP NET TENSION

(2040+ ONLY)

FIGURE 19

Table Tennis

Table

Back Of Robot

To Control

Box

Velcro

Straps

Robot

8,9

CT Support

Legs

95

Connector

Cable

Serial #

Located

Here

10,11,12

CT Support

Leg Rubber

Tip—Come

In 3 Sizes

So Center

Trough Will

Sit Level.

Support Flange Of Robot Sits

Fully Down On Locating Tab Of

Center Trough or Ball Bucket

15

Ball Dam

In Storage

Position

5

CT Front

Support Plate

32

Wing

Nut

1

Center Trough

(Should Be Level)

SUPPORT FLANGE ALIGNMENT

& SERIAL # (2040+ ONLY)

FIGURE 17

Velcro

Straps

Summary of Contents for Robo-Pong 1040+

Page 27: ...TRAINING LOG 27 DATE TIME NOTES...

Page 28: ...28 DATE TIME NOTES...