21

40mm balls. If unsure of ball size, check with Ball Dam.

B. Ball Speed Motor is not running. See Problem 14.

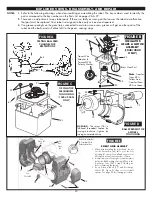

C. Friction Block is missing or not functioning properly.

See Solution 4F.

D. Ball Discharge Wheel has come off. Reattach.

E. Ball Speed Motor is running backwards. See Problem 13.

F. Balls are too small. Check with Ball Dam. See page 11.

6. PROBLEM

Robot shoots erratically. Some balls delivered high, others

low or off to the side or ball speed changes without the Ball

Speed knob being turned.

SOLUTIONS

A. Friction Block is dirty, worn or defective. If dirty, clean;

otherwise, replace.

B. Ball Discharge Wheel is dirty, worn, out of round,

cracked, or loose. If loose, tighten; if dirty, clean;

otherwise, replace.

C. Ball Speed Motor mounting screws are loose. Tighten.

D. Slots in Robot Head Housings for Friction Block tabs

and/or 2mm spacers of the Ball Size Switches are

worn. Replace housings.

E. Ball Discharge Spring is defective. See Solution 18F.

7. PROBLEM

Robot shoots more than one ball at a time.

SOLUTIONS

A. Ball Discharge Spring has come off or is damaged.

Replace.

B. Using new, dirty, low quality, or oversized balls. Wash

and dry new or dirty balls. After washing new balls, be

sure to use rub down procedure. Check balls with a

Ball Dam to be sure they are the correct size and

roundness. See page 11.

OSCILLATOR PROBLEMS

1,2

8. PROBLEM

Oscillator motor runs, but head does not move.

1,2

SOLUTIONS

A. Control Levers are set to 1,6. Reposition. See page 9.

1,2

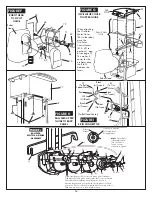

B. A gear post, lever, or the Control Lever Adapter has

broken. Replace. See Figures B & G, pages 24 & 25.

1,2

C. Oscillator is not assembled correctly. Be sure top pin of

Pivot Guide is inserted inside the hole on the bottom of

the Oscillator Motor Cover and that the bottom pin of

the Pivot Guide is in the corresponding hole of the

Upper Guide.

9. PROBLEM

Oscillator operates, but Oscillator Control Levers jump out

of place while oscillator is running.

1,2

SOLUTION

A. Control Levers are bent or cracked. Levers can

sometimes be bent back into shape when softened by

heating. Otherwise, replace.

10. PROBLEM

Oscillator operates, but motion is jerky and/or straining

noises are heard.

1,2

SOLUTION

A. Oscillator Motor Cover is pressing down on the

Control Levers, restricting their movement. Remove

cover and file or scrape away a small amount of the

bottom edge of the cover that is directly above the

levers.

11. PROBLEM

Robot does not deliver the ball all the way to either the left or

right corner of the table when spin is set to straight topspin

or backspin, Control Levers are set to positions 3 & 4, and

robot is in position 1 or 5 (Figure 15, page 12).

1,2

SOLUTIONS

A. See Solutions 8B, 8C, 9A, 10A, & 10B.

1,2

B. Make sure fit of Control Lever Adapter to Pivot Guide

is very tight. If loose, replace Control Lever Adapter

and/or Pivot Guide.

C. Be sure Clear Front Cover is properly attached.

D. Plastic pins on top and bottom of Oscillator Pivot

Guide are not straight and exactly perpendicular to the

top and bottom surfaces. If either pin is crooked,

replace Pivot Guide.

E. Defective Friction Block. Replace. See Figure E, pg. 24.

F. If problem persists after eliminating all other solutions,

you may intentionally twist the robot and/or mount

the robot off-center towards the problem corner.

12. PROBLEM

Robot head drifts away from intended direction when

oscillator is turned off.

1,2

SOLUTION

A. Set Control Levers to positions 3 & 4. See page 9.

1,2

GENERAL MOTOR PROBLEMS

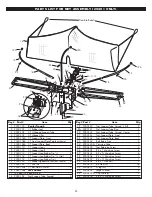

13. PROBLEM

Ball Speed Motor or Ball Feed Motor runs backward.

SOLUTION

A. The 5 Pin Connector is incorrectly wired or the motor

connections are reversed. In either case, switching the

wires on the motor will correct the problem. See

Figures E & J, on pages 24 & 25.

14. PROBLEM

One or two motors don't run, but the others run normally.

SOLUTIONS

A. One or more wires inside the Connector Cable are

broken. Examine the cable by plugging it in and

turning on the power. Adjust knob controlling the

inoperative motor to 10, other knobs to 0. Then twist,

turn, push, and pull a small section of cable at a time

trying to get the broken wires inside the cable to make

contact with one another. If the inoperative motor

suddenly starts running, you have found the break.

Also cable can be checked with a voltmeter. Replace.

B. Check the 5-Pin Connector to see if two of the

terminals are touching or if a wire is not soldered

securely to its terminal. If so, carefully bend the

terminals apart to keep them from touching or

resolder the connection.

C. A wire to the problem motor is unattached. Reattach.

D. Wires attached to motor are shorting each other out.

Bend terminals apart so wires don’t touch each other.

E. If the problem is either the Ball Feed or Oscillator

Motor

1,2

, check the nylon transfer gears connected to

the motor for obstructions or wear. Clean and relub-

ricate sparingly with a light grease. Replace any gears

with worn teeth. See Figures B & J, pages 24 & 25.

F. Motor is “frozen” (especially likely if robot has not

been used for awhile or is stored in a damp or humid

Summary of Contents for Robo-Pong 1040+

Page 27: ...TRAINING LOG 27 DATE TIME NOTES...

Page 28: ...28 DATE TIME NOTES...