PULL DOWN SUPPORT LEGS

Place the robot on the

table with the open

front side facing you.

Pull the curved black

metal support legs

toward you.

5

CONNECT CABLES TO CONTROL BOX

Bring the free end

o f C o n n e c t o r

Cable to the play-

er ’s end of the

table. Plug the Connector Cable

into the 5-pin socket on the bot-

tom of the Control Box. Then insert the Transformer’s pin

into the Power Jack of the Control Box (see Figure 1B, page 6).

ATTACH CONTROL BOX TO TABLE

Place the Control Box

on the side of the table

about one foot from

the end. If you're

right-handed, place it on the left side

of the table. If you're left-handed,

place it on the right side. (See Figure

15, page 12 for more detail.) Plug the Transformer into any

suitable electric power source. Transformer specifications

are printed on top of the Transformer.

7

6

GET READY TO PLAY!

Turn Oscillator Speed on and when the head

aligns with the centerline of the table, turn

Oscillator Speed off. Pick up your paddle,

turn the Ball Speed knob to 2–3 and the Ball

Frequency knob to 4–5. Turn the Power

switch to “on” and get ready to return the ball. It takes

about 30 seconds for the balls to load up before the first

one is delivered. When you’re ready for random delivery,

turn the Oscillator Speed on and the balls will be randomly

delivered across the entire table. To become more familiar

with the controls and adjustments for your machine, read

the O

PeraTiOn

section of this manual starting on page 6.

8

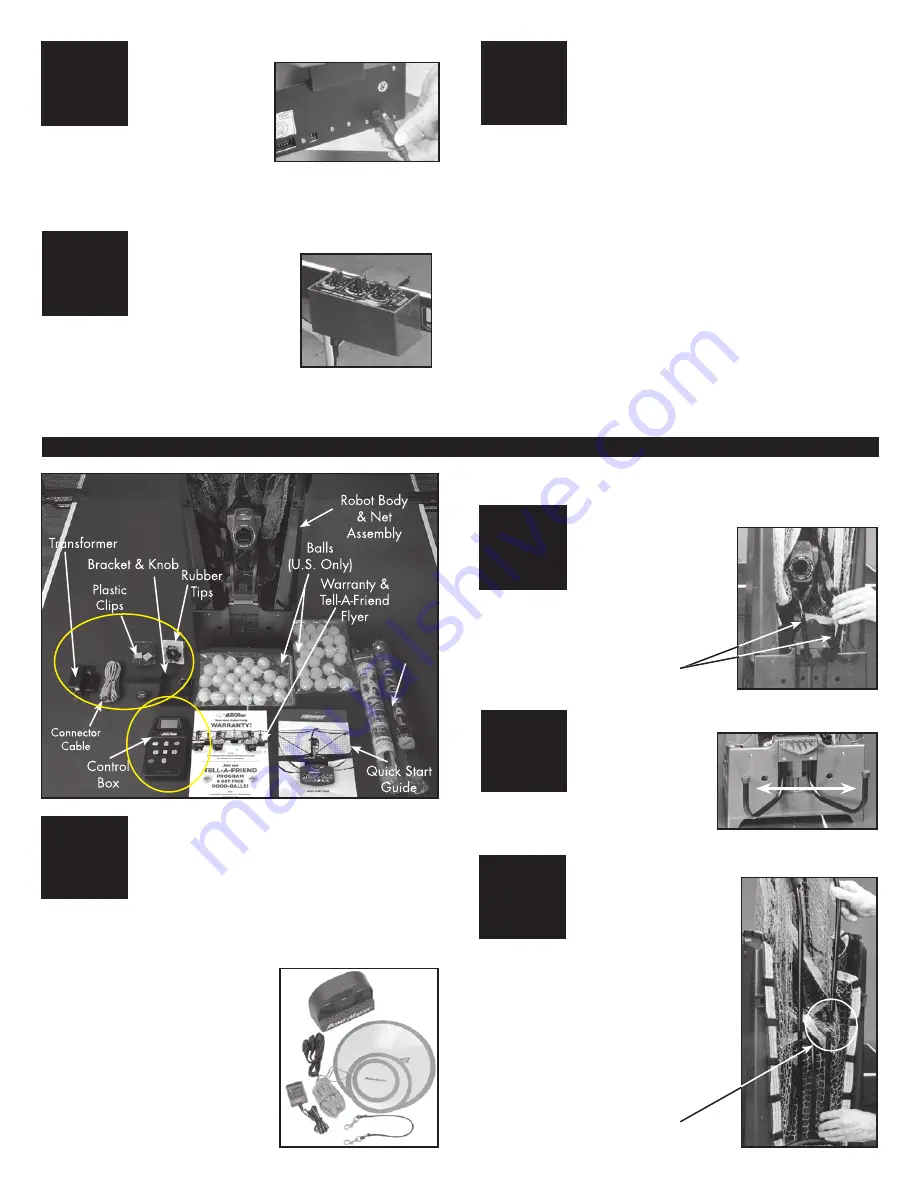

QUICK SET-UP FOR ROBO-PONG 2040+

VERIFY ALL PARTS

Unpack all the parts and check that all are

present. If unable to identify a part, look for

a small silver label with the part name. If a

part is missing, please contact Newgy. You

may want to keep your box and styrofoam pieces in case

you need to ship your robot. If you purchased Pong-Master,

check the photo below to verify all of its parts. In your

Owner’s Packet is a separate

O

wner

’

s

M

anual

for Pong-

Master. That manual will tell you

how to set up and operate Pong-

Master. To help you separate

robot parts from Pong-Master

parts, the silver labels have “RP”

before the part names for the

robot and a “PM” before the part

names for Pong-Master.

1

SPREAD SUPPORT LEGS APART

Spread out the sup-

port legs to their

fully open position.

JOIN NET SUPPORT TUBES

Turn the robot around

1 8 0 ° s o t h e N e t

Support Tubes are now

facing you. Grasp the

second tube from the right and pull

up, removing it from its storage hole.

Place the bottom of this tube into the

top of the first tube on the right as

shown. Repeat on the left side.

2

3

4

Support Legs

Joining Net Support Tubes

➨

➨

➨

Pong Pal

(U.S. Only)

Summary of Contents for Robo-Pong 1040+

Page 27: ...TRAINING LOG 27 DATE TIME NOTES...

Page 28: ...28 DATE TIME NOTES...