ensure that no reflections back into the lens.

Window Material and Color

Many window materials include stresses and distortions, which leads to poor performance. So use only cell-cast plastics or

optical glass. There are three common window materials, chemically tempered glass, PMMA and ADC. Below are the

recommended window features.

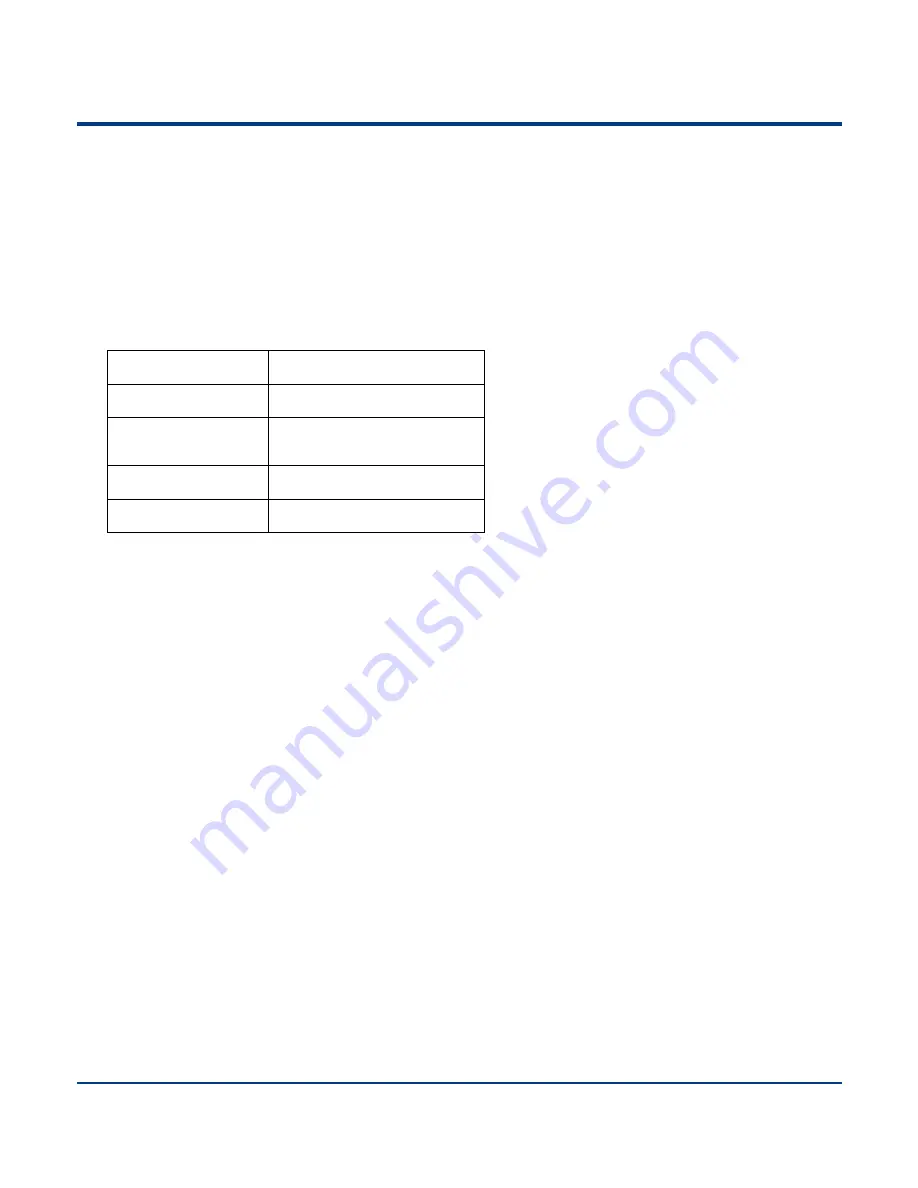

Table 2-3

Feature

Description

Thickness

Generally 0.8-2.0mm

Wavefront Distortion

PV maximum:

0.2λ

RMS maximum: 0.04λ

Clear Aperture

To extend the area within 1.0mm

Surface

60-20 scratch/dig

Consider the wavefront distortion when using plastic materials.

Plastic materials are not recommended if the window is designed as tilted, because scratches will reduce the performance.

If the motion detection mode is needed, colored windows are not recommended as well.

Wavelength of the illumination and aiming light should be taken into consideration when choosing window material and

color, in order to achieve the possible highest spectral transmission, lowest haze level and homogeneous refractive index.

It is suggested to use PMMA or optical glass with spectral transmittance of red light over 90% and haze less than 1%.

Whether to use an anti-reflection coating or not depends on the material and application needs.

PMMA

PMMA is made by casting acrylic between two sheets of glass. It obtains the advtanges of high quality, good impact

resistance and low cost, while it is soft and brittle. Polysiloxane coating is recommended to avoid attack from stresses.

Acrylic is enabled to be cut into kinds of shapes and welded ultrasonically.

ADC

ADC obtain good chemical and environmental resistance and impact resistance. Because of its hardness, coating is not

required except some terrible circumstances. Ultrasonical welding is not allowed.