3

FIG. 3 - FAN AND LIMIT CONTROLS

Settings: Fan off – 95 F, Fan on – 130 F. High limit – 210 F for CL-115-170C&G, 180 F for CL-86-96C&G

NOTE: For constant fan operation, push the MANUAL-AUTO switch on button to MAN position.

5.

Connect wiring as in Fig. 12 (All models).

6.

Install the oil storage tank or tanks according to the instructions supplied by the manufacturer of the pump.

7.

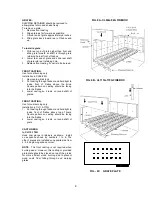

Install brick in firebox according to Fig. 9A for CL-86-96 G, Fig. 8B for CL-86-96C, and Fig. 8A for CL-115-170C. For grate

installation in CL-86-96G refer to Fig. 9A and for grate and cast liner installation in CL-115-170G refer to Fig. 9B.

8.

Do not use a manual flue pipe damper with this furnace.

9.

Caution

: If this furnace is used as a replacement for an existing furnace make sure there is a minimum of 6” clearance

above the warm air plenum as far as 6 feet out from the furnace. Beyond 6 feet there must be a minimum of 1/2”

clearance.

This furnace must be connected to a chimney approved for wood burning appliances , ie. ULC S629 (Canada) and UL103 (US).

Newmac recommends an 8” round or 8” square chimney flue (inside dimension), however, this may be reduced to a 7” providing

there is enough draft at the appliance to operate as designed. It is the responsibility of the installer to ensure there is sufficient draft

in all cases. Draft should be between -0.03 and -0.05 ins wc. No other appliance should be connected to this chimney flue, unless

the installation conforms to clause 5 of B365 and providing there is sufficient draft.

amended April 2003

The installation must conform with the regulations of the local authorities having jurisdiction with the applicable Electrical Code,

and C.S.A. Standard B139 “The Installation Code for Oil Burning Appliances and Equipment” and with the regulations in C.S.A.

Standard B365 “The Installation Code for Solid Fuel Burning Appliances and Equipment” when pertaining to supply air plenum

clearances and flue pipe installation. The flue pipe must be black 24 ga pipe minimum.

The flue collar is sized so that a trade size flue pipe fits snugly inside it. Joints in flue pipes, including the connection at the

appliance and the chimney, shall have at least 30mm (1 3/16”) overlap. Flue pipe connections must be secured with at least 3

metal screws or an equivalent mechanical means; and be made tight in accordance with good practice.

The flue products may contain carbon monoxide particularly when the wood fire is being starved for air (made to burn at slow

rate). Therefore, the flue pipe must seal tight and must not be inserted into the return air stream of the circulating blower.

Wood storage should conform to local bylaws, and should not be within minimum clearances for combustible surfaces as

shown above. This furnace must be installed by a qualified furnace serviceman.

COMBUSTION AIR:

Where fans are used in the fuel storage area, they should be installed so as not to create negative

pressure in the room where the solid fuel burning appliance is located.

OUTSIDE COMBUSTION AIR:

Provision for outside combustion air may be necessary to ensure that fuel-burning appliances

do not discharge products of combustion into the house. Guidelines to determine the need for additional combustion air may

not be adequate for every situation. If in doubt, it is advisable to provide additional air.

Summary of Contents for CL 115-170C

Page 7: ...6 FIG 6 FLUE PIPE CONNECTION MINIMUM INSTALLATION CLEARANCES...

Page 8: ...7 FIG 7 CONTROL LOCATIONS...

Page 18: ...17 FIG 10 TYPICAL A C COIL INSTALLATION...

Page 19: ...18 FIG 11 WIRING DIAGRAM WITH AIR CONDITIONING...

Page 20: ...19 FIG 12 CL SERIES WIRING DIAGRAM...

Page 21: ...20 FIG 13 COMBINATION AIR FLOW FIG 14 AIR CONDITIONING INSTALLATION...

Page 26: ...25 FIG 16 1G THERMO DISC MOUNTING ON BURNER PLATE...