6

P.O. Box 1306

Newport Beach

California 92663

Phone: 714-751-0488

Fax: 714-957-1621

E-Mail: techservice@newmarpower.com

Output Voltage Table

Factory Set “V OUT” “V OUT”

Model

Output Voltage

Adjustment Range

PM-12-40A,

13.6V DC

12.2 - 15V DC

Current Limit Circuit:

The PM is rated for continuous duty at the current

level indicated by model number, e.g., PM-12-40A is rated at 40 amps con-

tinuous duty. To prevent overload when recharging severely discharged

batteries, current is limited at approximately 105 % of the continuous duty

rating by a current fold-back circuit.

DC Fuses:

d.c output wiring is protected by internal DC output fuse(s). The

current limiting circuit of the PM should prevent these fuses from blowing

under normal operating conditions. If the d.c fuse(s) blow, this may indicate

a reverse polarity hook-up or an internal short.

Always disconnect AC to the PM before checking fuses. To replace the

DC fuse, the cover must be removed. The DC fuses are ATC blade type

mounted on the small PCB. Be sure to replace with the same type and

value as indicated on the fuse.

If the battery is connected to the PM output with backwards polarity, the

fuses should blow to protect DC wiring. However damage to internal

components may also have occurred. If the replacement fuse blows, return

the PM to the factory for a thorough inspection.

C) Cooling Fans

To maximize the life of the internal components and to allow continu ous

operation at full rating, the PM employs automatic cooling fans. These fans

operate at full speed whenever AC is applied and the unit is producing DC

output.

Preventative Maintenance: The fan is a maintenance-free ball-bearing

type and does not require lubrication. It is equipped with a filter to keep

debris from being sucked into the unit. It is recommended that this filter be

removed and rinsed with water occasionally to ensure adequate air flow,

particularly if the PM is installed in a dusty or particle-filled environ ment.

Simply pry off the filter retainer with a flat tip screwdriver to clean or replace

the filter.

If the fan fails to operate when the PM is turned on and a load is applied,

it may need to be replaced. (Replacement fans available from NEWMAR.

Specify part number 999-1208-0, Replacement Fan with PCB connector.)

Fan Replacement Procedure

Note: It is recommended that both fans be replaced at the same time, even

if only one has failed.

1. Disconnect ac power from PM.

2. Remove the plastic fan filter retainer on each fan. Use a small slotted

screwdriver if necessary. Remove filters.

3. Unscrew the four philips head screws that secure the fans to the PM.

Remove the four white plastic stand-offs from each fan along with the

plastic finger guards. Install the finger guards, stand-offs and screws on

to the replacement fans.

4. Un-plug the two 2 conductor fan powerleads from the mating connector. .

5. When installing replacement fan:

A. Make sure each fans cable passes through the slot in the front

panel and does not impede fan blade rotation.

B. Make sure the fan air flow, which is indcated by an arrow on the

top of the fan, points into the Power Module.

6. Attach fans to PM with the eight screws and re-install fan filters (clean

first) and filter retainers.

7. Re-connect ac power to PM and confirm fans operate.

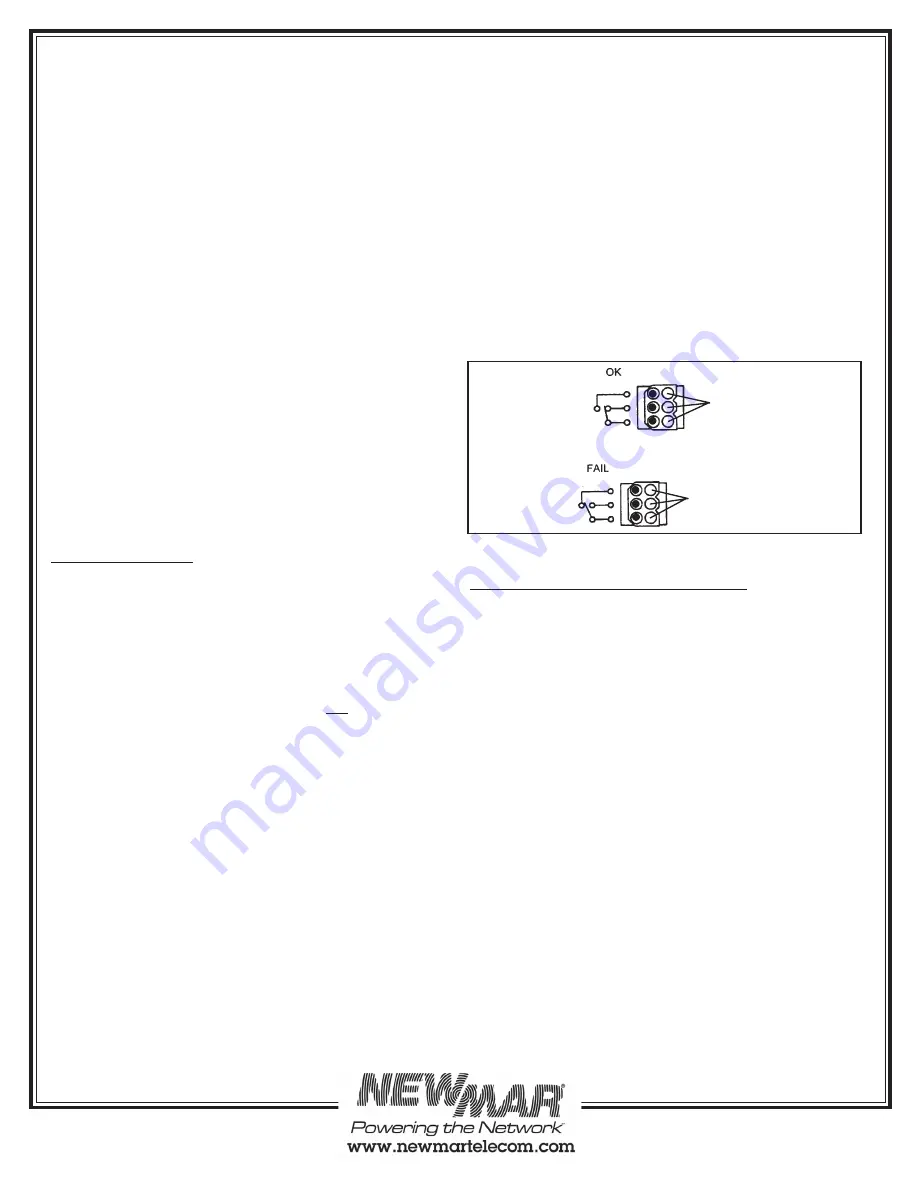

D) Local/Remote Alarm

A loss-of-output relay (form “C”) is wired to the output connector on the

rear panel. When wired to an external alarm or remote indicator lamp it will

alert the operator in the event of any condition which causes a loss of DC

output.

A color-coded wire “pigtail” with keyed plug is provided for wiring

convenience and to assure proper connections. The plug holds three wires

for the output fail relay.

The alarm may be wired with the relay “normally open” or “normally

closed”, as needed. The position of the contacts during DC output failure

and normal operating condition is illustrated below:

Figure 12: DC “FAIL” and DC “OK” Relay Contact Positions

Note:

The three right-hand connector positions are unused in this installation

Relay contact rating for all models is 5a @ 30V DC

V) Options (Available from the Factory)

A) DC Quick Connect Wiring Kit

Note: This option is available only for systems which incorporate the

NEWMAR Power Function Manager. For complete information on this

product, please contact the factory.

A DC wiring harness quick connect kit is available from NEWMAR which

simplifies parallel wiring installation of multiple Power Modules with the

Power Function Manager and facilitates “hot change-out” of modules for

repair or replacement.

The kit consists of two wiring harness; one for positive and negative DC

output wiring, another for alarm contact wiring. Wires are pre-cut to proper

length, all necessary connectors are installed and the bundles are neatly

tie-wrapped into proper position for a simple and professional installation.

For more information, or to order the quick connect kit, please contact the

factory and specify the number of PM’s (2-6) in the system being installed.

Model QCK-3: 1-3 PM’s. Model QCK-6: 4-6 PM’s.

B) AC Transient Suppressor

For communication sites which are subject to “dirty” AC voltage with line

transients or spikes, a commercially available AC transient suppressor may

be required.

Unused

Positions

Unused

Positions

Unused

Positions

Unused

Positions