13

3.2

Maintenance Instructions

3.2.1

Checking oil level

Check oil level through the sight glass weekly to make sure the oil level is

aligned with the red marker line next to the sight glass (See Figure 3). Add or

remove oil as needed.

3.2.2

Draining air tank condensate

Run the compressor to pressurize the air tank, then switched off the

compressor.

Move the air compressor to an appropriate place for draining

purposes.

Use a container underneath the drain valve to prevent spilling.

Slightly tilt your ACWS Series air compressor forward and release

the drain valve (see Figure 4, open about a ¼ turn) to let the

condensate out.

Close the drain valve.

3.2.3

Draining the air outlet filter

Run the compressor to pressurize the air tank, then switch off the

compressor.

Use a container below the filter to prevent any spilling.

Turn the knob underneath the air outlet filter open to let moisture out

(see Figure 4).

Close the knob when finished.

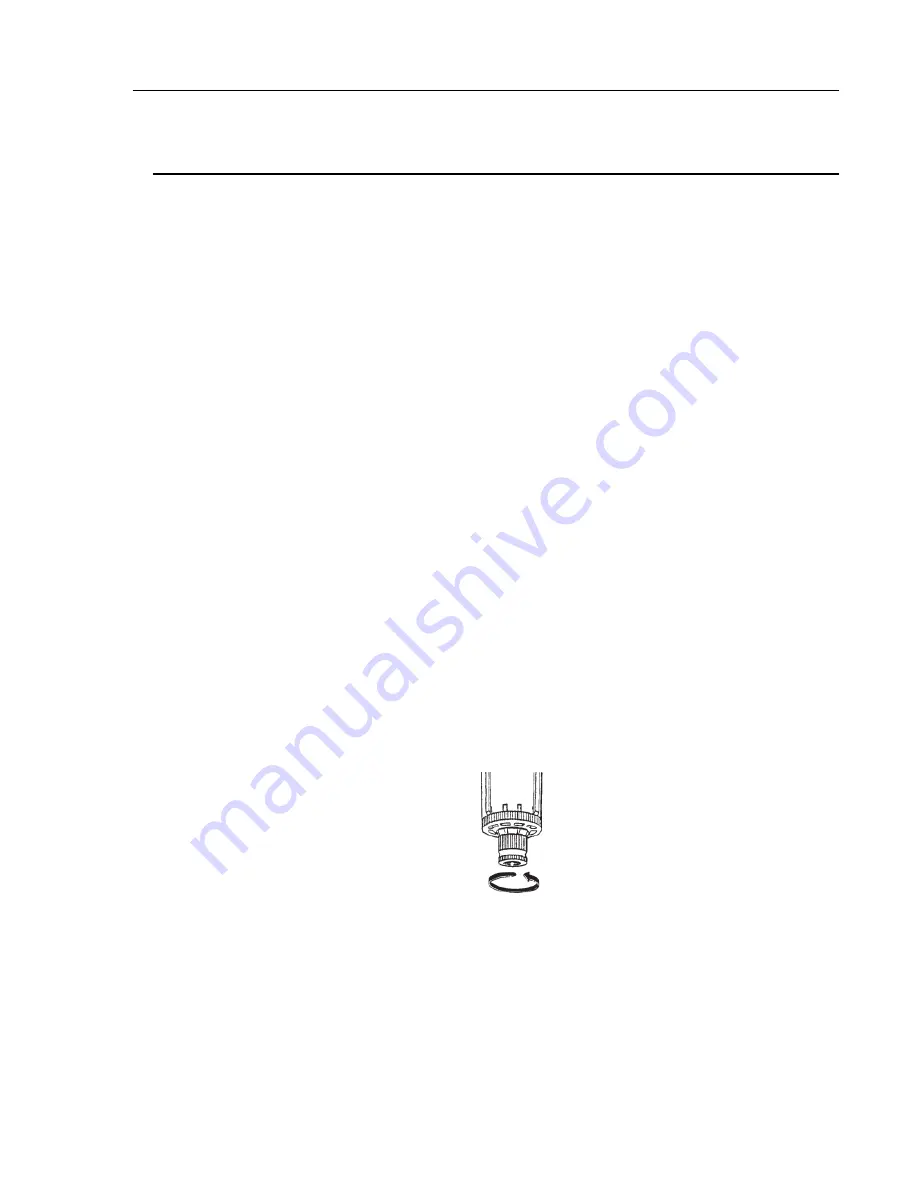

Figure 5

Outlet filter bottom knob