4.11

EDH0162En1040 – 06/99

MM4005

Motion Control Tutorial

The dynamic Load Capacity refers to the motor’s effort to move the load.

The first parameter to determine is how much load the stage can push or

pull. In some cases the two values could be different due to internal

mechanical construction.

The second type of dynamic Load Capacity refers to the maximum load

that the stage could move with the nominal acceleration. This parameter is

more difficult to specify because it involves defining an acceptable follow-

ing error during acceleration.

4.2.12

Maximum Velocity

The Maximum Velocity that could be used in a motion control system is

determined by both motion device and driver. Usually it represents a lower

value than the motor or driver are capable of. In most cases and in particu-

lar for the MM4005, the default Maximum Velocity should not be increased.

The hardware and firmware are tuned for a particular maximum velocity

that cannot be exceeded.

4.2.13

Minimum Velocity

The Minimum Velocity usable with a motion device depends on the motion

control system but also on the acceptable velocity regulation. First, the

controller sets the slowest rate of motion increments it can make. The

encoder resolution determines the motion increment size and then, the

application sets a limit on the velocity ripple.

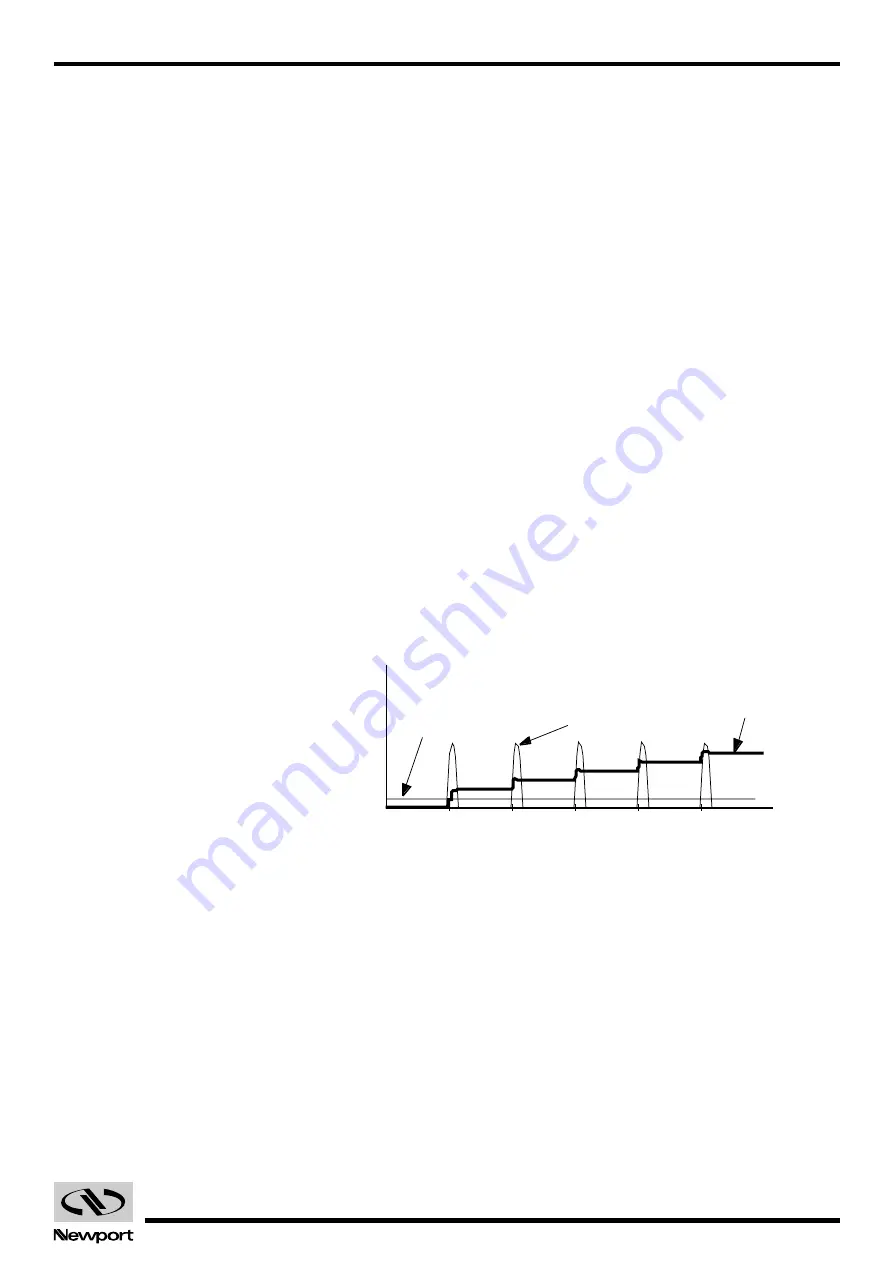

To illustrate this, take the example of a linear stage with a resolution of 0.1

µm. If we set the velocity to 0.5 µm/sec, the stage will move 5 encoder

counts in one second. But a properly tuned servo loop could move the

stage 0.1 µm in about 20 ms. The position and velocity plots are illustrated

in Fig. 4.12.

Fig. 4.12

— Position, Velocity and Average Velocity.

The average velocity is low but the velocity ripple is very high. Depending

on the application, this may be acceptable or not. With increasing velocity,

the ripple decreases and the velocity becomes smoother.

This example is even more true in the case of a stepper motor driven stage.

The typical noise comes from a very fast transition from one step position

to another. The velocity ripple in that case is significantly higher.

In the case of a DC motor, adjusting the PID parameters to get a softer

response will reduce the velocity ripple but care must be taken not to nega-

tively affect other desirable motion characteristics.

1 s

Position

Velocitymoy

Average

Velocity

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com