EDH0162En1040 – 06/99

4.16

MM4005

Motion Control Tutorial

The second observation is that the desired velocity is calculated by the tra-

jectory generator and is known ahead of time. The obvious conclusion is

that we could take this velocity information, scale it by a K

vff

factor and

feed it to the motor driver. If the scaling is done properly, the right amount

of voltage is sent to the motor to get the desired velocities, without the

need for a closed loop. Because the signal is derived from the velocity pro-

file and it is being sent directly to motor driver, the procedure is called

velocity feed-forward.

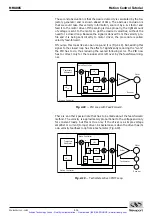

Of course, this looks like an open loop, and it is (Fig. 4.18). But, adding this

signal to the closed loop has the effect of significantly reducing the “work”

the PID has to do, thus reducing the overall following error. The PID now

has to correct only for the residual error left over by the feed-forward sig-

nal.

Fig. 4.18

— PID Loop with Feed-Forward.

There is an other special note that has to be made about the feed-forward

method. The velocity is approximately proportional to the voltage and only

for constant loads. but this is true only if the driver is a simple voltage

amplifier or current (torque) driver. A special case is when the driver has its

own velocity feedback loop from a tachometer (Fig. 4.19).

Fig. 4.19

— Tachometer-driven PIDF Loop.

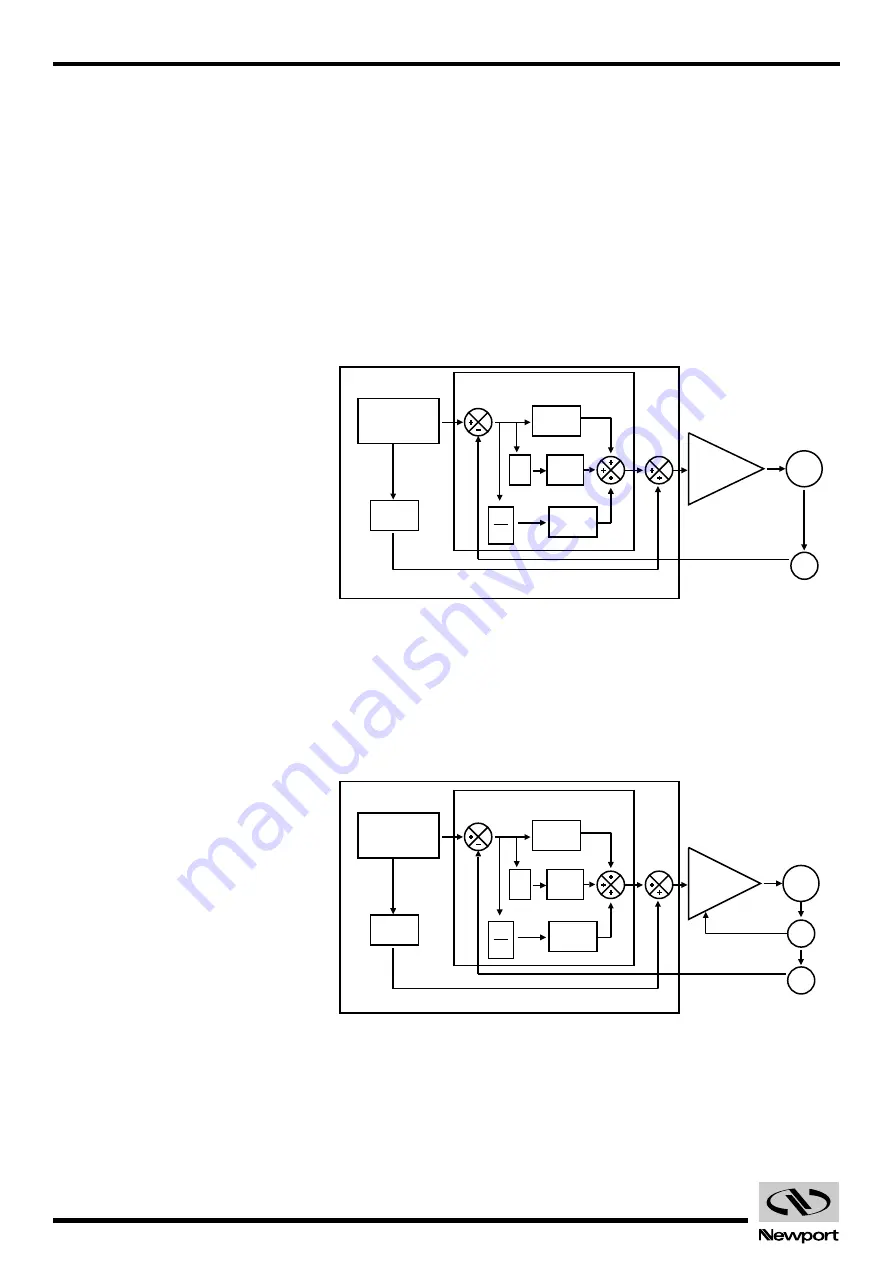

X

K

p

X

K

i

X

K

d

X

K

vff

de

dt

e

Trajectory

Generator

Motion Controller

Servo Controller

Driver

Motor

Encoder

Tachometer

∫

e

X

K

p

X

K

i

X

K

d

X

K

vff

de

dt

e

Trajectory

Generator

Motion Controller

Servo Controller

Driver

Motor

Encoder

∫

e

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com