NewRider™ 1700 HPA Airless Ride-on Sprayer

ALWAYS wear safety goggles or protective eye-wear when operating the unit

!

NewRider™ 1700 HPA Manual / 4026.0916

Page 2 of 3

1.

Check for any damage that may have occurred

during shipment. Advise factory immediately if you

see any damage. Remove the unit from the crate

by removing the top boards, then the boards at the

ends of the crate. Remove the tie down straps and

then remove any shipping cartons.

2.

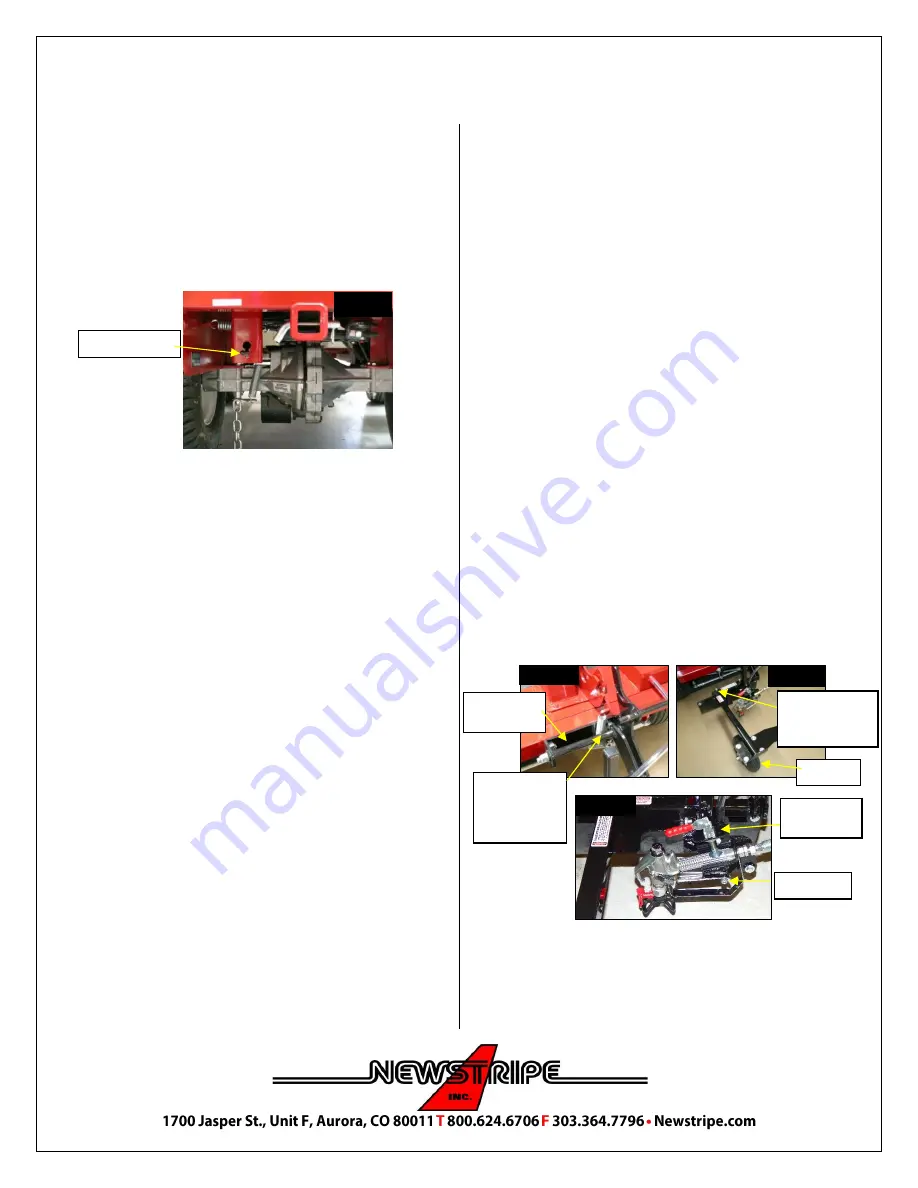

Access the transaxle release lever at the rear of the

machine. Pull the lever up, push in and then down

to disengage. (Picture 1)

3.

Release parking brake if applied. You should be

able to roll the machine out of the crate by pushing

on the rear bumper. DO NOT STAND IN FRONT OF

THE MACHINE WHILE ROLLING OUT OF CRATE.

4.

Locate the battery access cover in front of the

purge tank. Remove the 4 bolts with washers and

access cover.

5.

Connect the battery ground cable to the negative

side of the battery. Re-install battery cover.

6.

Mount the spray head support by aligning the two

holes in the bumper bracket with the two holes in

the frame. Insert two ½”x3” bolts in the holes from

the front. Place one washer and one nylock nut on

each bolt and tighten.

7.

Cut the tie that secures the lift lever lock spring to

the machine. Hook the bottom of the spring into

the loop in the bottom of the mounting bracket.

8.

Press on foot release for the spray head (lever on

the left side of the steering column) to lower the

spray head support tube.

9.

Mount the spray head caster assembly by sliding

the caster arm onto the spray head support tube

and tighten bolts. The caster wheel may be

adjusted to the left or right so that the rear wheels

will clear the striped line when turning. (Picture 2)

10.

Slide the spray gun mounting bracket over the

upright on spray head support tube and tighten

bolt. Adjusting the spray gun mounting bracket up

or down will adjust the spray width. (Picture 3)

11.

Place the spray gun in the holder without the hose

attached and secure with the clamp. (Picture 4)

12.

The spray gun may have to be moved forward or

backward in the clamp so that there is

approximately 1/8” of space between the trigger

and the lifting bar. This should also leave enough

room to push the trigger lock sideways. (Picture 4)

13.

If the trigger lock will not push release the gun

clamp and slide gun forward or backward until you

can push the trigger lock. Re-clamp gun.

NOTE: To release trigger lock push the lock in on

the right side (inside) of the gun.

14.

Attach one end of the spray hose to the pump

outlet with a ¾” wrench and the other end to the

spray gun. To secure the hose on the spray gun you

will need a 3/4” and a 9/16” wrench as it has a

swivel fitting.

15.

Loop the additional hose over the hanger on the

left side of the spray tank. Make sure hose does

not contact the tire. Route the hose through the

snap link and around post at corner of left fender.

16.

Always check the oil level in the engine before

starting (SAE 10W30)

17.

Make sure the static chain is contacting the

ground.

NOTE: The NewRider 1700 is Equipped with an

EPA/Carb approved recovery system and tethered

fuel cap. DO NOT SERVICE OR REMOVE THE VAPOR

CANISTER OR TEATHERED FUEL CAP FROM THE

MACHINE. DO NOT REPLACE ANY FUEL SYSTEM

PARTS WITH NON APPROVED PARTS.

Lifting bar

Raised

position

locking lever

spring

Spray Head

Support

Caster

Spray Head

with mounting

tube

Trans Release lever

Picture 1

Picture 3

Picture 2

Spray Gun

release

clamp

Picture 4

Summary of Contents for NewRider 1700 HPA

Page 1: ...NewRider 1700 HPA Airless Ride on Sprayer NewRider 1700 HPA Manual 4026 0916 ...

Page 2: ......

Page 4: ......

Page 26: ......