10

FORM NO. L-20063-AG-1216

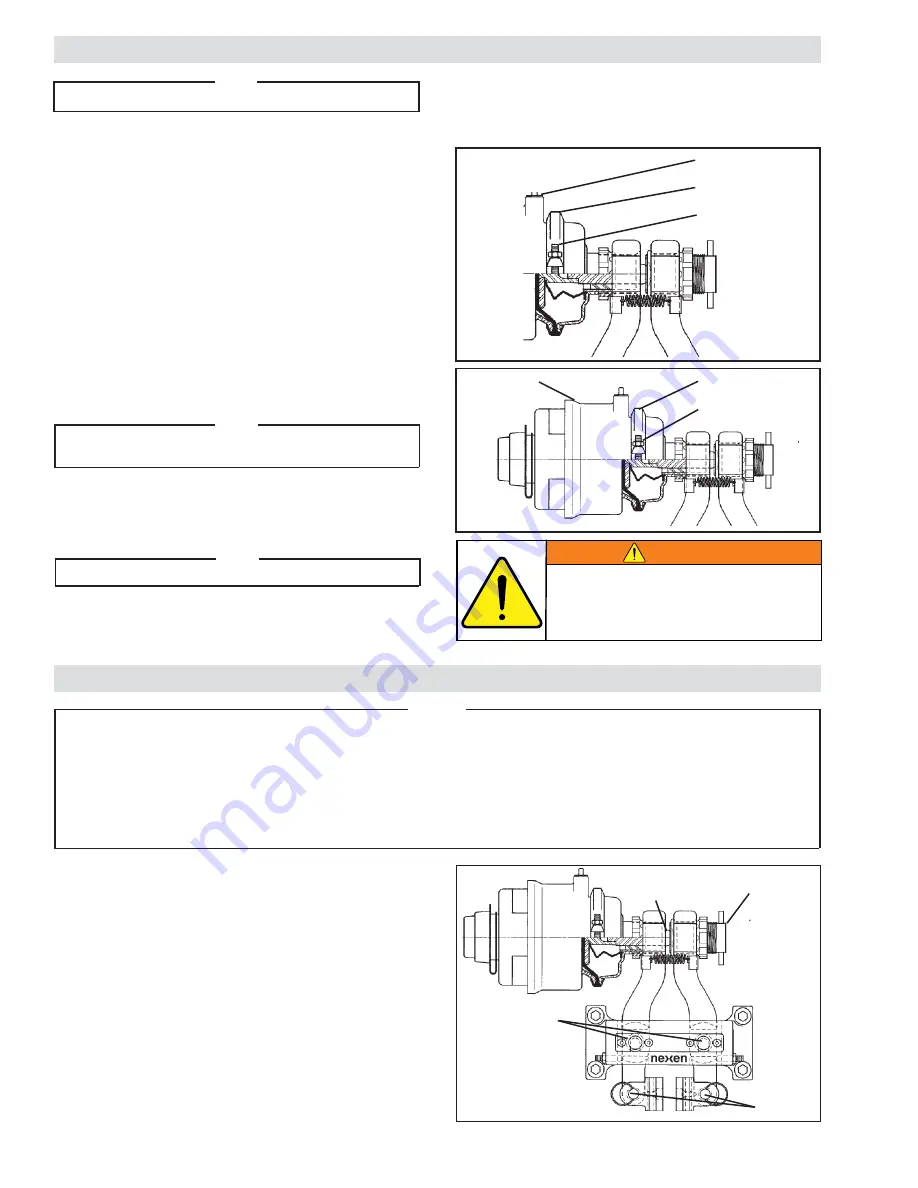

Figure 7

Actuator

Ring Clamp Bolt

Ring Clamp

Figure 8

Actuator

Ring Clamp

Ring Clamp Bolt

NOTE

Maximum operating pressure is 6.90 bar [100 psi].

Pneumatically actuated devices require clean, pressure

regulated, and lubricated air for maximum performance and

long life. Your Nexen Distributor carries filters, regulators,

and lubricators specifically designed to operate with Nexen

clutches, brakes, and valves.

Piping diagrams are included in this manual for a variety

of braking functions. Refer to OPERATIONAL MODES

(See Page 12-14).

The actuator air connections may be rotated 360

o

by

loosening the Ring Clamp and rotating the Actuator Head.

If the actuator is spring engaged, first deactuate the brake

and cage the spring.

1. Apply hold-off air pressure to release the spring Actuator

(See Figure 6).

Note

Before performing step two, determine the actuator type

and select either step 2a or 2b.

2.

Manual Disengagement:

Refer to pages 16 & 17 for

manual disengagement and re-engagement instructions.

3. Adjust the ring clamp as required.

Note

Tighten Ring Clamp Bolts to 25-35 ft-lbs [34-47 Nm] torque.

AIR CONNECTIONS–GENERAL

A Hose Assembly (Item 23) is supplied and must be

connected to the brake with sufficient slack to allow the

Arms (Item 2) full movement without putting stress on the

hose or hose couplings.

Do not use rigid pipe or tubing when connecting

directly to the brake. Care must also be taken

to prevent an unshielded air hose from rubbing

on metal surfaces or edges; this will cause rapid

deterioration of the hose.

WARNING

LUBRICATION

FIGURE 9

Piston Rod

(Item 10)

Bearing

(Item 15)

Bearing

(Item 14)

Adjustment

Screw

(Item 8)

All pivot points on the BD Caliper Brake use self-lubricated

high PV bearings.

For tension control applications where the disc is held at

elevated temperatures for extended periods, use a light

machine oil on Bearings (Items 14 and 15) (See Figure 9).

The sliding spherical contact between the Adjustment Screw

(Item 8) and Piston Rod (Item 10) should be lubricated

with a molybdenum disulfide based grease (See Figure 9).

NOTE

Nexen pneumatically actuated devices require clean, pressure regulated air for maximum performance and life.

All seals in Nexen pneumatically operated devices are lubricated for life, and do not require additional lubrication.

However, some customers prefer to use an air line lubricator, which injects oil into the pressurized air, forcing

an oil mist into the air chamber. This is acceptable, but care must be taken to ensure once an air mist lubrica-

tion system is used, it is continually used over the life of the product as the oil mist may wash free the factory

installed lubrication.

Locate the lubricator above and within ten feet of the product, and use low viscosity oil such as SAE-10.

Synthetic lubricants are not recommended.