14

FORM NO. L-20063-AG-1216

TABLE 4

M

E

T

I

N

O

I

T

P

I

R

C

S

E

D

E

U

Q

R

O

T

4

2

s

w

e

r

c

S

p

a

C

]

b

l-

tf

7

-

5

[

m

N

9

-

7

--

g

n

i

R

p

m

a

l

C

r

o

t

a

u

t

c

A

)t

u

N

d

n

a

tl

o

B

(

]

b

l-

tf

5

3

-

5

2

[

m

N

2

.

7

4

-

7

.

3

3

9

1

s

w

e

r

c

S

p

a

C

]

b

l-

tf

0

5

[

m

N

5

.

7

6

2

1

t

u

N

r

e

n

n

a

p

S

]

b

l-

tf

5

1

-

0

1

[

m

N

3

.

0

2

-

6

.

3

1

--

e

b

u

T

g

n

it

n

u

o

M

r

o

t

a

u

t

c

A

)t

u

N

r

e

n

n

a

p

S

(

]

b

l-

tf

5

1

-

0

1

[

m

N

3

.

0

2

-

6

.

3

1

--

tl

o

B

p

a

T

)

y

l

n

o

d

e

g

a

g

n

e

-

g

n

ir

p

S

(

]

b

l-

tf

5

1

-

0

1

[

m

N

3

.

0

2

-

6

.

3

1

8

1

w

e

r

c

S

e

n

i

h

c

a

M

]

b

l-

tf

2

1

-

8

[

m

N

5

1

-

2

1

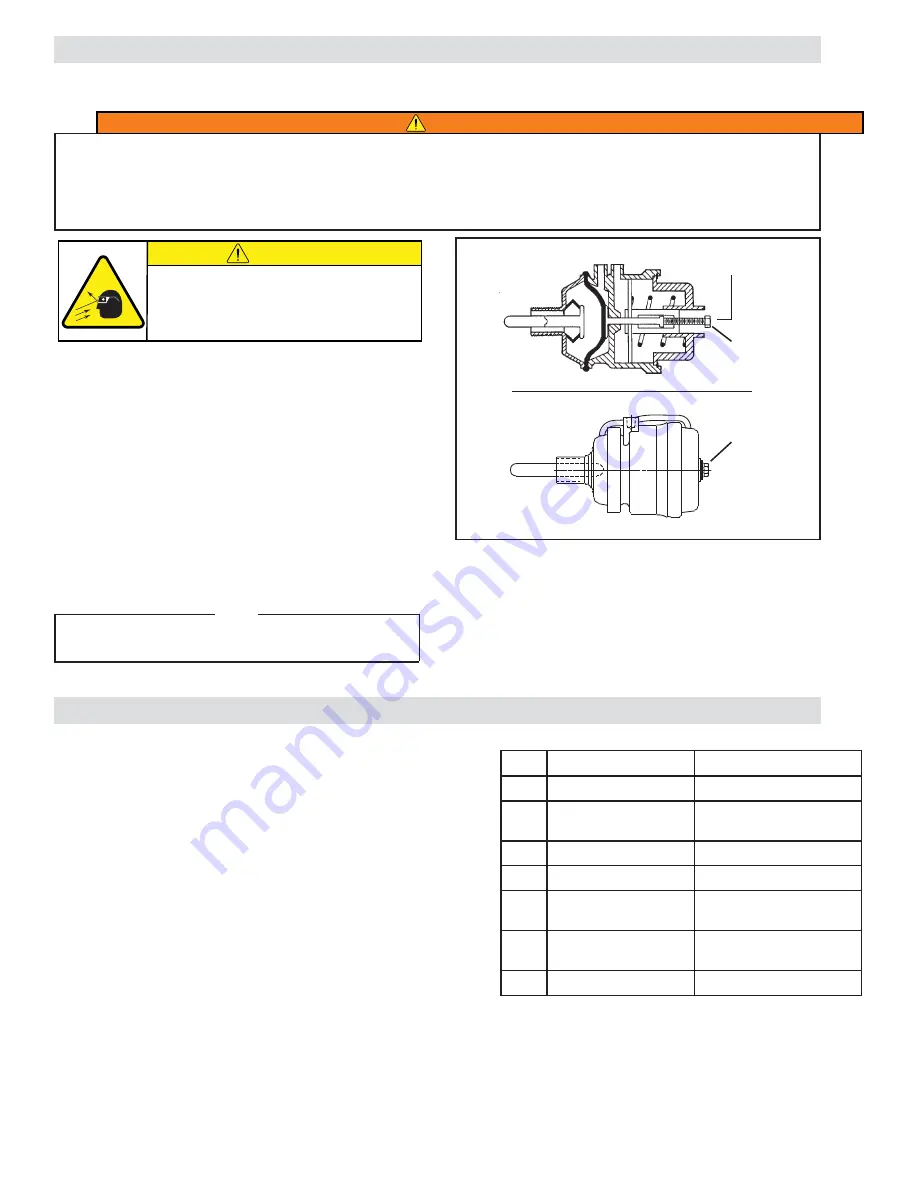

1. Adhere to the following bolt torques (See Table 4).

2. Clean Breather Cap air filter when dirty (spring engaged

unit only).

3. Inspect canister exterior for damage. Replace canister

if damaged.

4. Check tightness of all air line connections and condition

of all air lines. Replace air lines if deterioration exists.

5. Inspect friction facings for wear. Replace if worn to

approximately 5/16 inch thick.

6. Lubricate items requiring lubrication (See

LUBRICATION).

MAINTENANCE

The use of 3/4 inch wide discs with the BD Caliper Brake requires a shorter Piston Rod (Item 10) and Return Springs

(Item 17) for proper operation. (Not applicable for the 60 psi canister.)

OPTION KIT FOR 3/4" WIDE DISC INSTALLATION (INCLUDED WITH BRAKE)

1. Remove Return Spring (Item 17) and Shoes (Item 3)

by removing Shoe Pins (Item 16) (See Figure 15).

2. Loosen the Spanner Nut (Item 12) and turn the

Adjustment Screw (Item 8) counterclockwise until it is

fully disengaged (See Figure 15).

3. Open the Arms (Item 2) at the actuator end and replace

the Piston Rod (Item 10) (See Figure 19).

4. Reinstall the Shoes (Item 3), Shoe Pins (Item 16), and

Return Spring (Item 17) (See Figure 15).

5. Reengage the brake.

NOTE

On spring engaged BD Caliper Brakes, apply hold-off

air pressure and:

Tap Bolt located under

Breather Cap.

Figure 15a

Figure 15b

9/16" Hex

Head

3/4" Hex

Head

Refer to pages 16 & 17 for manual disengagement and

re-engagement instructions.

6. Perform friction facing adjustment (See FRICTION

FACING CLEARANCE ADJUSTMENT).

CAUTION

Working with spring loaded or tension

loaded fasteners and devices can cause

injury. Wear safety glasses and take the

appropriate safety precautions.

WARNING

Spring actuated brakes must be manually released prior to brake disassembly.

Refer to pages 16 & 17 for manual disengagement and re-engagment instructions.

Hold-off air pressure can be removed once unit is manually disengaged, and service performed

(See Figure 15 a & b).

WARNING