18

FORM NO. L-20063-AG-1216

WARNING

Spring actuated brakes must be manually released prior to brake disassembly.

Refer to pages 16 & 17 for manual disengagement and re-engagment instructions.

Hold-off air pressure can be removed once unit is manually disengaged, and service performed

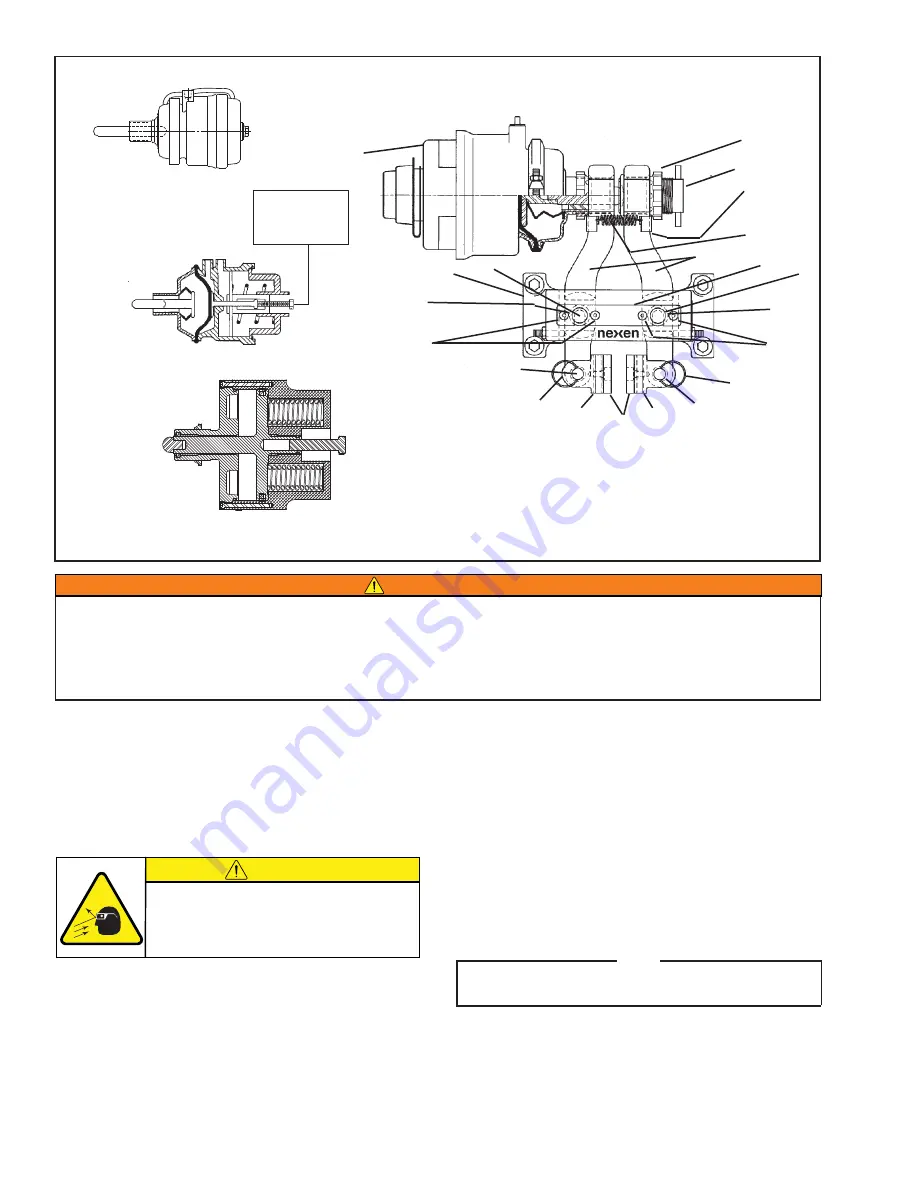

(See Figure 17 a, b & c).

7. Remove the four Cap Screws (Item 24) securing the

Pivot Pin Retainer Plate (Item 6).

8. Remove the Pivot Pin Retainer Plate (Item 6).

9. Press the Pivot Pins (Item 7) out of the BD Caliper

Brake.

10. Slide Arms (Item 2) out of Main Frame (Item 1).

11. Press the damaged Bearings (Item 14) out of the Main

Frame (Item 1).

12. Press new Bearings (Item 14) into the Main Frame

(Item 1).

Note

The tops of the Bearings must be flush with the top

of the Main Frame (Item 1).

13. Press the damaged Bearings (Item 15) out of the Shoes

(Item 3).

14. Press new Bearings (Item 15) into Shoes (Item 3).

15. Slide the Arms (Item 2) back into the Main Frame

(Item 1).

Refer to Figure 19.

1. Loosen the Spanner Nut (Item 12).

2. Remove the Adjustment Screw (Item 8) and the Spanner

Nut (Item 12) from the Arm (Item 2).

3. Remove the Actuator (Item 11) from the other Arm

(Item 2).

4. Remove the Return Springs (Item 17) and Spring

Retainers (Item 5) from the Arms (Item 2).

5. Remove the Shoe Pins (Item 16) from the Arms (Item

2), Friction Facings (Item 4), and Shoes (Item 3).

6. Slide the Friction Facings (Item 4) and Shoes (Item 3)

off of the Arms (Item 2).

HIGH PV BEARINGS (ITEMS 14 AND 15)

FIGURE 19

12

8

11

2

17

5

16

16

4

3

3

24

24

6

7

14

7

14

1

15

15

Tap Bolt

located under

Breather Cap.

Two-Port

Actuator

Three-Port

Actuator

60 PSI

Actuator

CAUTION

Working with spring loaded or tension

loaded fasteners and devices can cause

injury. Wear safety glasses and take the

appropriate safety precautions.

WARNING