9

FORM NO. L-20063-AG-1216

SPRING ACTUATED

Note

Friction facing adjustment on spring actuated units is

accomplished while the brake is not actuated. Apply hold-

off air pressure of 5.17-6.90 bar [75-100 psi] to release the

spring Actuator.

1. Apply hold-off air pressure to release the spring Actuator

(See Figure 6).

Note

Before performing step two, determine the actuator type

and select either step 2a or 2b. Step four returns to general

instructions used for both models.

2.

Manually Disengage Brake:

Refer to pages 16 &

17 for manual disengagement and re-engagement

instructions.

3. Loosen the adjustment screw Spanner Nut (Item 12)

(See Figure 5).

4. Turn the Adjustment Screw (Item 8) until a 1/32 inch

spacer can be slid between each of the Friction Facings

(Item 4) and the Friction Disc (See Figure 5).

5. Turn the Adjustment Screw in until the spacer can just

be pulled out.

6. Tighten the Spanner Nut (Item 12) to 13.6-20.3 Nm

[10-15 ft-lb] torque.

Note

Ensure proper hold-off pressure has been maintained.

(This will remove any tension on the tap bolt for easier

release.)

7.

Manual Re-Engagement:

Refer to pages 16 & 17 for

manual disengagement and re-engagement.

8. Remove hold-off air pressure to engage the spring

Actuator.

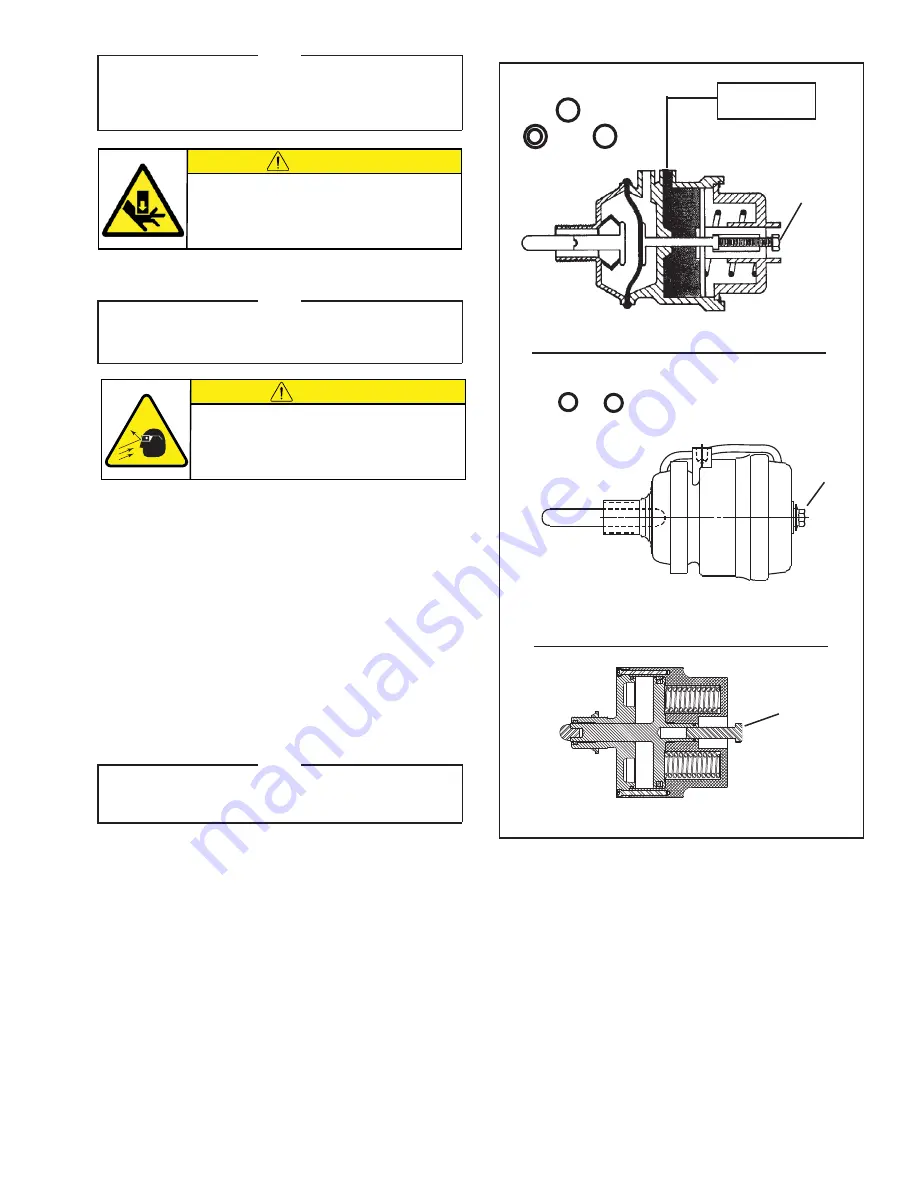

Figure 6a

Obsolete Three-Port Actuator

SPRING BRAKE

SERVICE

SERVICE

Apply Hold-Off

Air Pressure

Figure 6b

Two-Port Actuator

Spring Brake

Service

9/16"

Hex Bolt

3/4" Hex

Bolt

Figure 6c

60 PSI Actuator

15/16" Hex

Head

CAUTION

This product has possible pinch

points. Care should be taken when

interacting with this product.

CAUTION

Working with spring loaded or tension

loaded fasteners and devices can cause

injury. Wear safety glasses and take the

appropriate safety precautions.