12

FORM NO L-20347-H-1112

TABLE 5

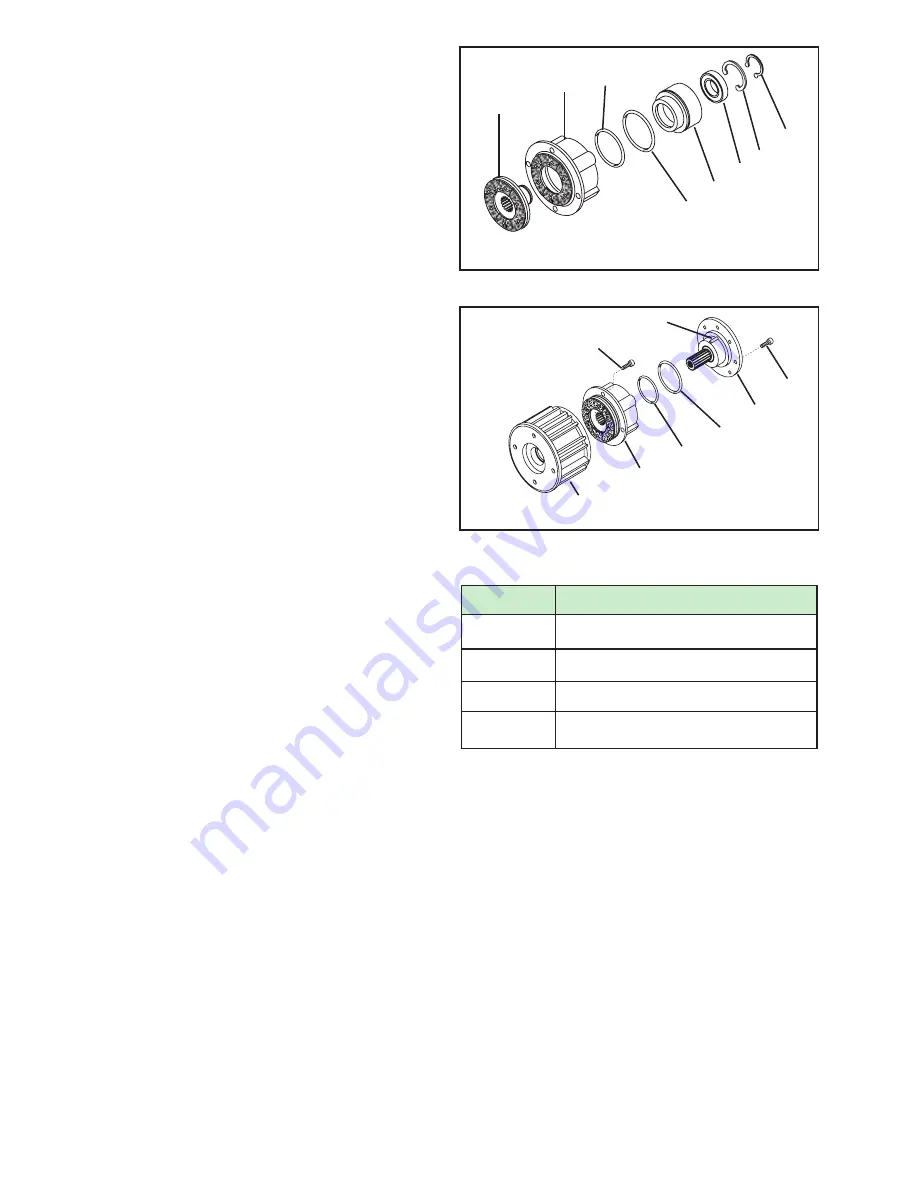

13. Slide the Piston (Item 16) out of the Air Chamber

(Item 12) (See Figure 16).

14. Remove the O-ring Seals (Items 14 and 15) from

the Piston (Item 16) and the Air Chamber (Item 12)

(See Figure 16).

15. Remove the Retaining Ring (Item 3) from the Piston

(Item 16) (See Figure 16).

16. Press the old Ball Bearing (Item 2) out of the Piston

(Item 16) (See Figure 16).

17. Clean the bearing bore of the Piston (Item 16) with

fresh safety solvent, making sure all old Loctite

®

residue is removed (See Figure 16).

18. Apply an adequate amount of Loctite

®

680 to evenly

coat the outer race of the new Ball Bearing (Item

2); then, press the new Ball Bearing (Item 2) into

the Piston (Item 16) and reinstall the Retaining Ring

(Item 3) (See Figure 16).

19. Lubricate the new O-ring Seals (Items 14 and 15)

and the contact surfaces on the Piston (Item 16)

and Air Chamber (Item 12) with a thin film of fresh

o-ring lubricant (See Figure 16).

20. Install the new O-ring Seals (Items 14 and 15) (See

Figure 16).

21. Slide the Piston (Item 16) back into the Air Cham-

ber (Item 12) (See Figure 16).

22. Support the inner race of the Ball Bearing (Item 2)

located inside the Piston (Item 16) and press the

Splined Disc (Item 9) into the Air Chamber (Item

12) and Piston (Item 16) (See Figure 16).

23. Reinstall Retaining Ring (Item 6) (See Figure 16).

24. Lubricate the new O-ring Seals (Items 21 and 22)

and the contact surfaces on the Male Pilot (Item 20)

and Air Chamber (Item 12) with a thin film of fresh

o-ring lubricant (See Figure 17).

25. Install the new O-ring Seals (Item 21 and 22) (See

Figure 17).

26. Align the Spring Pin (Item 17) on the Male Pilot

(Item 20) with the hole in the Piston (Item 16) and

slide the Male Pilot into the Piston and Housing

(Item 1) (See Figure 17).

FIGURE 16

9

16

3

12

14

15

2

6

FIGURE 17

1

12

22

21

20

13

13

17

27. Apply a drop of Loctite

®

242 to the threads of four

Socket Head Cap Screws (Item 13) and secure the

Male Pilot (Item 20) to the Air Chamber (Item 12)

(See Figure 17).

28. Tighten the four Socket Head Cap Screws to the

recommended torque (See Table 4).

29. Apply a drop of Loctite

®

242 to the threads of four

Socket Head Cap Screws (Item 13) and secure the

Male Pilot (Item 20) and Air Chamber (Item 12) to

the Housing (Item 1) (See Figure 17).

30. Tighten the four Socket Head Cap Screws to the

recommended torque (See Table 5).

L

E

D

O

M

E

U

Q

R

O

T

G

N

I

N

E

T

H

G

I

T

D

E

D

N

E

M

M

O

C

E

R

5

2

6

-

E

B

C

M

F

]

b

l-

tf

5

.

0

1

[

m

N

7

1

.

4

1

5

7

8

-

E

B

C

M

F

]

b

l-

tf

5

.

4

2

[

m

N

2

2

.

3

3

5

2

1

1

-

E

B

C

M

F

]

b

l-

tf

5

.

4

2

[

m

N

2

2

.

3

3

5

7

3

1

-

E

B

C

M

F

]

b

l-

tf

5

.

9

4

[

m

N

2

1

.

7

6