4

FORM NO L-20347-H-1112

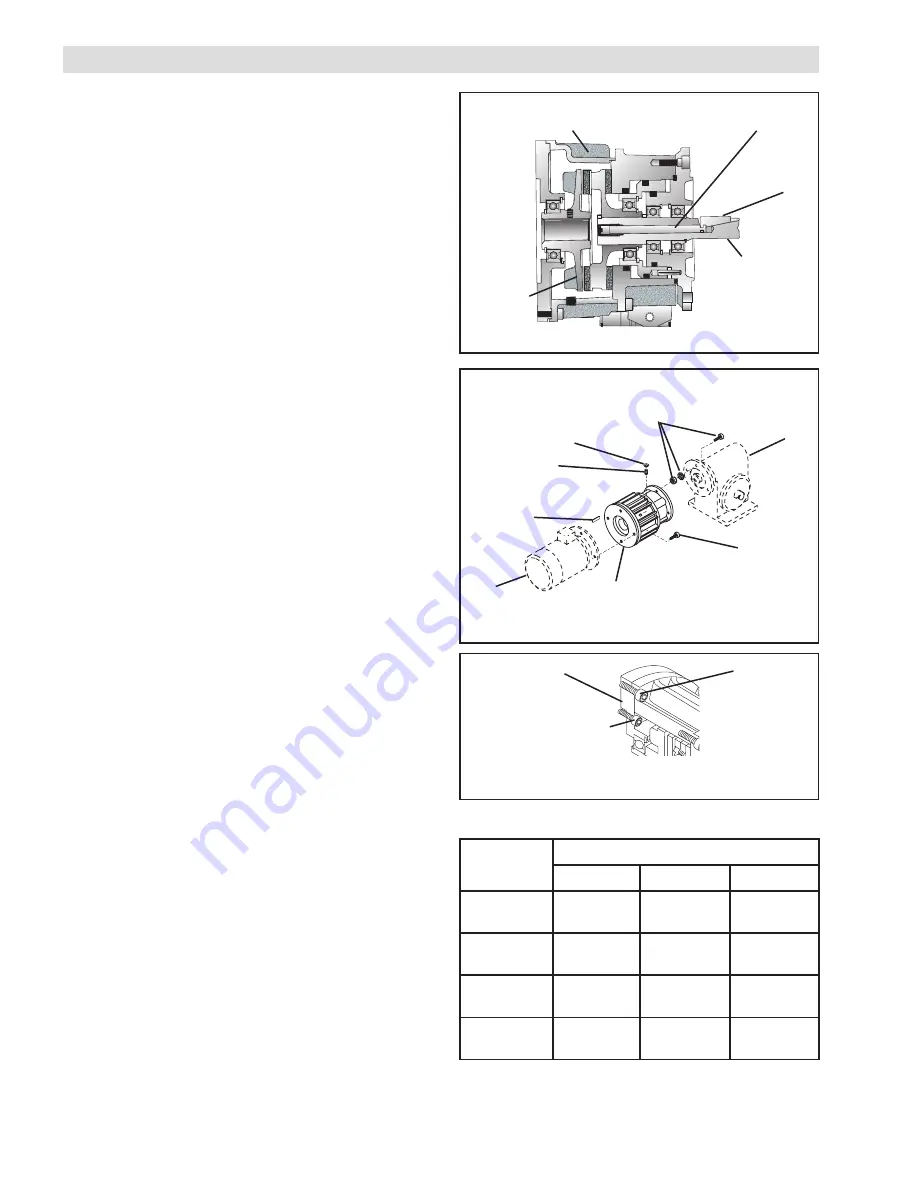

1. Coat the threads of the Bar (Item 38) with Loctite

®

242; then, thread the Bar into the Stub Shaft (Item

23) until the end of the Bar is visible in the keyway

slot of the Stub Shaft (See Figure 1).

2. Apply a thin film of Never-Seez

®

to Key (Item 25)

(See Figure 1).

3. Place the Key (Item 25) into the keyway of the Stub

Shaft (Item 23) (See Figure 1).

NOTE: Align the air inlet port to a down position to

allow condensation to drain out of the air chamber.

4. Slide the FMCBE output shaft into the gear reducer

(See Figure 2).

5. Secure the FMCBE to the gear reducer, using

customer supplied socket head cap screws, lock

washers, and nuts (See Figure 2).

6. Tighten the Bar (Item 38) to the recommended

tightening torque (See Table 1).

NOTE: Model 625 does not have a Female Pilot;

proceed with Step 8 for this model.

7. On Models 875, 1125 &1375, first remove the

Socket Head Cap Screws (Item 27) and Female

Pilot (Item 26); then, secure the Female Pilot to the

motor face using Socket Head Cap Screws (Item

29) and Lock Washers (Item 30). Tighten them to

recommended torque (See Table 1 and Figure 3).

8. Insert the customer supplied key into the motor

shaft keyway (See Figure 2).

9. On Model 625, secure the FMCBE to the motor

using Socket Head Cap Screws (Item 29) and

Lock Washers (Item 30) and tighten them to the

recommended torque (See Table 1 and Figure 2).

On Model 875, secure the Housing (Item 1) to

the Female Pilot (Item 26) using Socket Head

Cap Screws (Item 27) and tighten them to the

recommended torque (See Table 1 and Figure 3).

10. Align the tapped hole in the Drive Disc (Item 4) with

the hole in the Housing (Item 1) (See Figure 1).

NOTE: On Model 625, the Set Screw is Item 26.

On Models 875, 1125 and 1375, the Set Screw is

Item 31.

On Model 625 the Plug is Item 27. On Models 875,

1125 and 1375 the Plug is Item 32.

11. Tighten the Set Screw and install the Plug (See

Figure 2).

Customer

supplied

key

Set Screw

(Item 26 or 31)

Plug

(Item 27 or 32)

Socket Head Cap Screw

and Lock Washer

(Items 29 and 30)

Gear

Reducer

FIGURE 2

Motor

FMCBE

Housing

(Item 1)

Customer supplied

socket head cap screws,

lock washers, and nuts

TABLE 1

Bar

(Item 38)

Key

(Item 25)

Stub Shaft

(Item 23)

FIGURE 1

Housing

(Item 1)

Drive Disc

(Item 4)

INSTALLATION

L

E

D

O

M

E

U

Q

R

O

T

G

N

I

N

E

T

H

G

I

T

D

E

D

N

E

M

M

O

C

E

R

7

2

m

e

tI

9

2

m

e

tI

8

3

m

e

tI

5

2

6

-

E

B

C

M

F

A

/

N

m

N

5

.

3

6

b

l-

tf

3

.

8

4

m

N

8

.

6

]

b

l-

tf

5

[

5

7

8

-

E

B

C

M

F

m

N

4

2

.

4

1

]

b

l-

tf

5

.

0

1

[

m

N

5

.

3

6

b

l-

tf

3

.

8

4

m

N

8

.

6

]

b

l-

tf

5

[

5

2

1

1

-

E

B

C

M

F

m

N

2

2

.

3

3

]

b

l-

tf

5

.

4

2

[

m

N

0

.

1

6

1

b

l-

tf

8

.

8

1

1

m

N

9

.

4

1

]

b

l-

tf

1

1

[

5

7

3

1

-

E

B

C

M

F

m

N

2

1

.

7

6

]

b

l-

tf

5

.

9

4

[

m

N

0

.

1

6

1

b

l-

tf

8

.

8

1

1

m

N

0

.

6

1

]

b

l-

tf

6

1

[

Socket Head

Cap Screw

(Item 27)

FIGURE 3

Socket Head Cap Screw

and Lock Washer

(Items 29 and 30)

Female

Pilot

(Item 26)