7

FORM NO. L-20271-E-0300

15. Remove the Belleville Disc Springs (Item 8) and Thrust

Washer (Item 16) from the Rear Cylinder (Item 3) (See

Figure 11).

16. Coat the Thrust Washer (Item 16) with grease and slide

it into the Rear Cylinder (Item 3) (See Figure 11).

17. Liberally coat the 36 Belleville Disc Springs (Item 8) with

grease and stack them in series into the Rear Cylinder

(Item 3) (See Figure 11 and Insert A).

NOTE

Start first Belleville Disc Spring with its concave side

facing towards the Thrust Washer (Item 16).

18. Place the Small Washer (Item 15) on the Front Cylinder

(Item 2); then, place the Cylinder Head (Item 12) onto the

Front Cylinder and Small Washer (See Figure 11).

19. Press the Piston (Item 1) into the Front Cylinder and

Cylinder Head (See Figure 11).

20. Thread the two Alignment Pins (provided with the Actuator

Repair Kit, Product No. 933597) into the Rear Cylinder

(Item 3).

21. Align the hole patterns of the Cylinder Head and Front

Cylinder with the hole pattern of the Rear Cylinder; then,

slide the Cylinder Head and Front Cylinder over the

Alignment Pins.

REPLACEMENT PARTS

The item or balloon number for all Nexen products is used for

part identification on all product parts lists, product price lists,

unit assembly drawings, bills of materials, and instruction

manuals.

When ordering replacement parts, specify model designation,

item number, part description, and quantity. Purchase

replacement parts through your local Nexen Distributor.

PARTS LIST

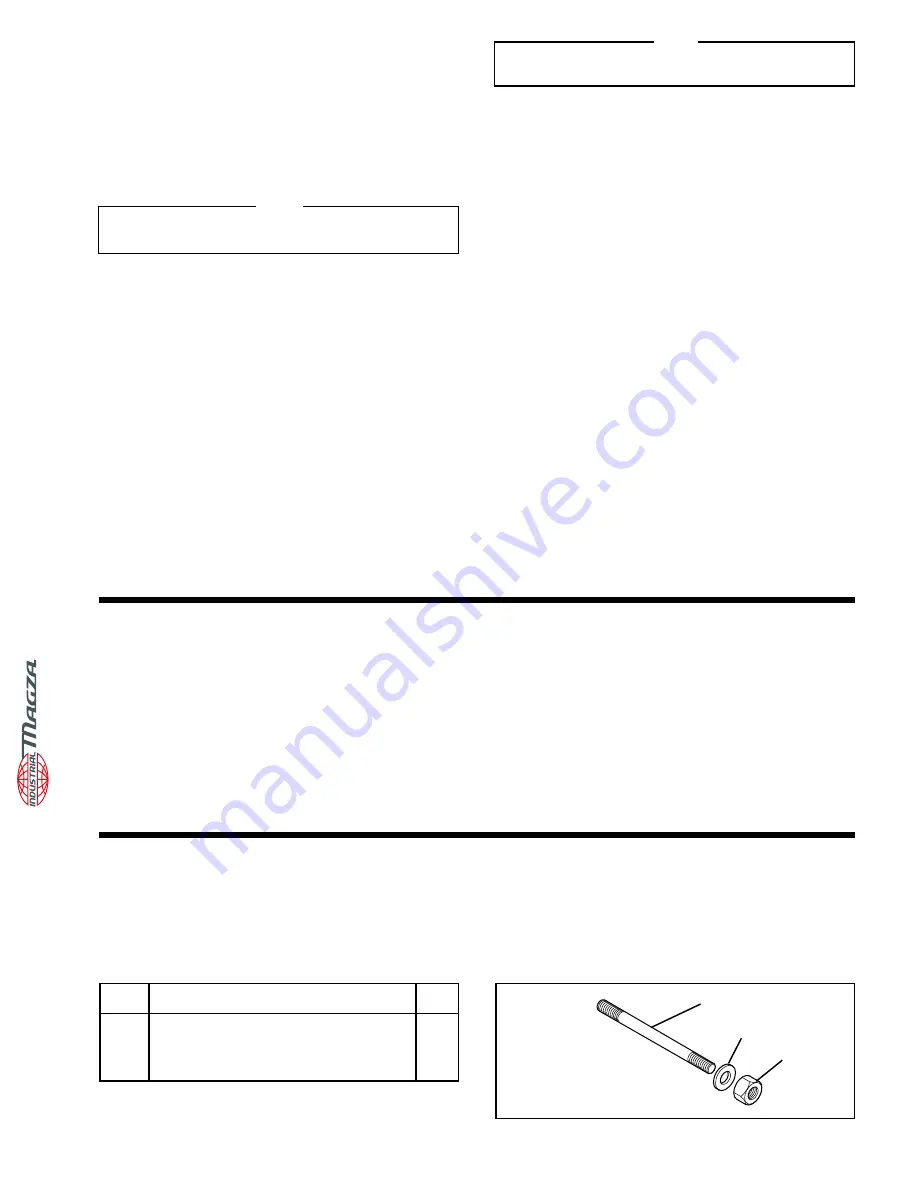

MANUAL RELEASE KIT (Product No. 933596)

ITEM

DESCRIPTION

QTY

1

Grade 5, 3/8-16 x 9'' Threaded Rod

1

2

3/8-16 Nut

1

3

3/8 Flat Washer

1

FIGURE 12

1

2

3

NOTE

1,500 Lbs. [6,672 N] of force is required to compress the

Belleville Washers.

22. Reinstall the Threaded Rod, Flat Washer, and Nut into the

back of the Actuator.

23. Tighten the Nut until the Belleville Disc Springs (Item 8)

are compressed and the Front Cylinder (Item 2) is flush

with the Rear Cylinder (Item 3).

24. Apply a drop of Loctite

®

242 to the threads of four Socket

Head Cap Screws (Item 10) and thread them into the Rear

Cylinder (See Figure 11).

25. Remove the two Alignment Pins.

26. Apply a drop of Loctite

®

242 to the threads of the two

remaining Socket Head Cap Screws (Item 10) and thread

them into the Rear Cylinder (See Figure 11).

27. Alternately and evenly tighten the six Socket Head Cap

Screws (Item 10) to 12 Ft. Lbs. [16.2 N•m] torque.

28. Reinstall the Actuator onto the BD Brake.

29. Loosely attach the Spanner Nut (Item 12) on the Actuator.

30. With the manual release still installed, perform friction

facing adjustment (See FRICTION FACING CLEARANCE

ADJUSTMENT).

®

DIST

. AUTORIZADO

MEX

(55) 53 63 23 31

QRO (442) 1 95 72 60

MTY (81) 83 54 10 18

ventas@industrialmagza.com