1

FORM NO. L-20271-E-0300

ACTUATOR

NOTE

This BD Caliper Brake is spring engaged and

hydraulically disengaged. To release the spring

pressure, remove the Vent, then lubricate and insert a

Grade 5, 3/8-16 x 9'' Threaded Rod into the back of the

Actuator; then, using a Flat Washer and Nut, tighten the

Nut to release the spring pressure (See Figure 4). A

Manual Release Kit (Product No. 933596) containing

these items is available from Nexen.

The actuator may be mounted on either side of the

brake.

1.

Remove the Detent Pins (Item 16) to release the Shoes

(Item 3) and the Belleville Disc Springs (Item 29) (See

Figure 2).

NOTE

Two Belleville Disc Springs (Item 29) are compressed

between the Brake Arm (Item 2) and the Shoe (Item 3).

When the Shoe is removed, the Belleville Disc Springs

will fall free from the Brake Arms.

2.

Remove the Shoes (Item 3) and Belleville Disc Springs

(Item 29) (See Figure 2).

3.

Remove four Cap Screws (Item 24) (See Figure 2).

INSTALLATION

DISC

1.

Thoroughly inspect the tapered bore of the disc hub and

the tapered surface of the Q.D. bushing. Remove any dirt,

grease, or foreign material. Do not use lubricants for this

installation.

2.

Assemble the Q.D. bushing into the disc hub, aligning the

untapped holes in the bushing flange with the tapped

holes in the disc hub.

3.

Insert the pull-up bolts and alternately and evenly tighten

to the recommended torque (See Tables 1 and 2).

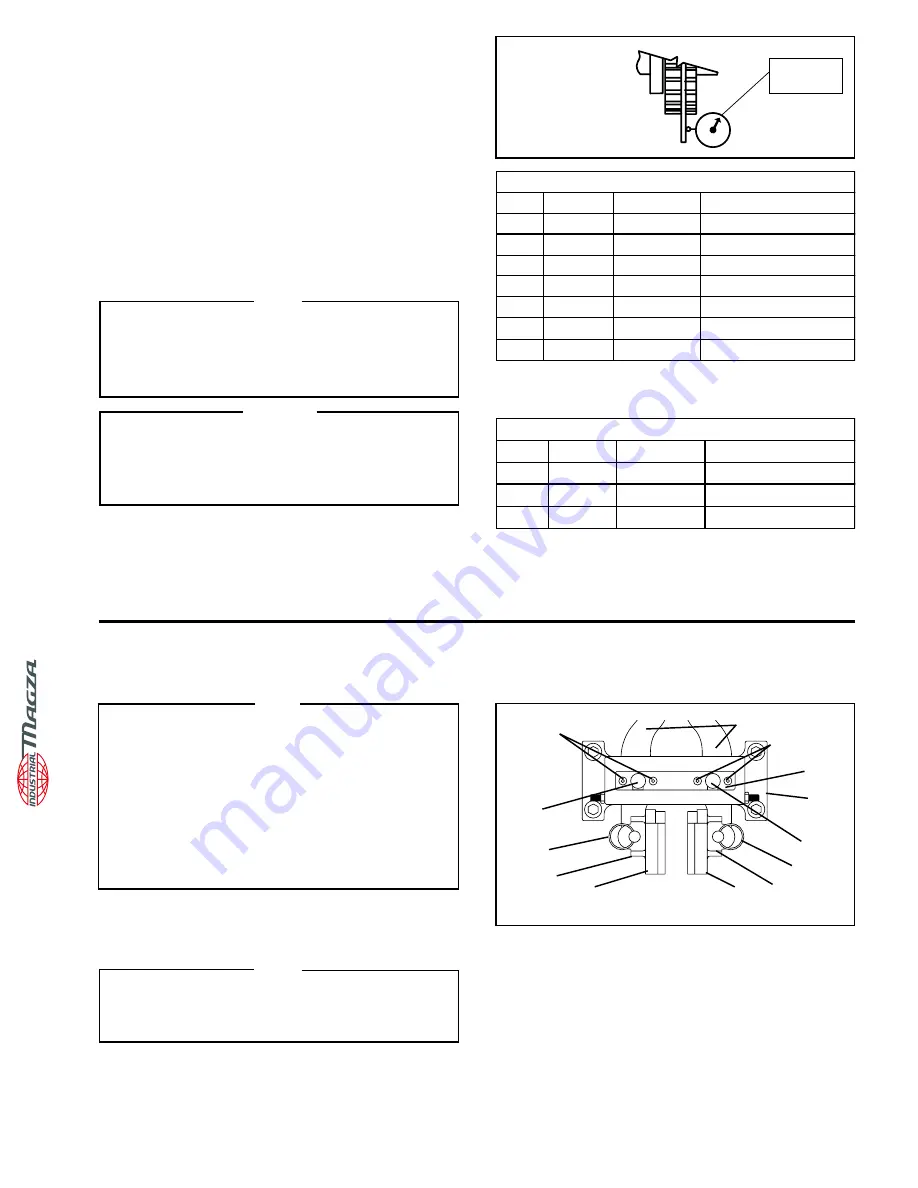

NOTE

Runout is minimized if a Dial Indicator is used as the

pull-up bolts are tightened. Place the contact tip of the

Dial Indicator on the machined surface of the rotor to

measure runout. Runout should be .010 - .015 In.

[2.5 - 3.8 mm] (See Figure 1).

CAUTION

If excessive tightening torque is applied, bursting

pressures are created in the hub. There must be a gap

between the flange of the Q.D. bushing and the disc hub

to ensure a proper press fit of the Q.D. bushing onto the

shaft.

Dial

Indicator

4.

Remove Pivot Pin Retaining Plate (Item 6) (See Figure 2).

5.

Press out Pivot Pins (Item 7) (See Figure 2).

6.

Slide Brake Arms (Item 2) out of Main Frame (Item 1) (See

Figure 2).

7.

Position the Brake Arms and Actuator as desired.

8.

Slide the Brake Arms (Item 2) back into the Main Frame

(Item 1) (See Figure 2).

24

24

2

6

1

7

16

29

3

7

16

29

FIGURE 2

3

FIGURE 1

4.

To remove the Q.D. bushing, remove the pull-up bolts and

reinsert into the threaded holes. Tighten the pull-up bolts

to push the disc hub off the Q.D. bushing.

RECOMMENDED TIGHTENING TORQUES

DIA.

PART NO.

QD BUSHING

TORQUE

12"

934201

SF

30 Ft. Lbs. [40.5 N m]

14"

934202

E

60 Ft. Lbs. [81 N m]

16"

932203

E

60 Ft. Lbs. [81 N m]

18"

934204

J

133 Ft. Lbs. [182.5 N m]

20"

934205

J

133 Ft. Lbs. [182.5 N m]

22"

934206

J

133 Ft. Lbs. [182.5 N m]

24"

934207

J

133 Ft. Lbs. [182.5 N m]

TABLE 1

PULL-UP BOLT TORQUES FOR NON-VENTILATED DISCS

RECOMMENDED TIGHTENING TORQUES

DIA.

PART NO.

QD BUSHING

TORQUE

18.25"

934200

J

135 Ft. Lbs. [182.5 N m]

21"

934300

J

135 Ft. Lbs. [182.5 N m]

24"

934400

J

135 Ft. Lbs. [182.5 N m]

TABLE 2

PULL-UP BOLT TORQUES FOR VENTILATED DISCS

®

DIST

. AUTORIZADO

MEX

(55) 53 63 23 31

QRO (442) 1 95 72 60

MTY (81) 83 54 10 18

ventas@industrialmagza.com