10

FORM NO. L-21699-B-1120

NOTE

For quick response, Nexen recommends a quick

exhaust valve and short air lines between the

Control Valves and the unit. Align the air inlet

ports to a down position to allow condensation

to drain out of the air chambers of the product.

CAUTION

Low air pressure will cause slippage

and damage.

All Nexen pneumatically actuated devices require clean

and dry air, which meet or exceeds ISO 8573.1:2001

Class 4.4.3 quality.

1.

Basic Configuration:

Attach a Standard Air Fitting to the Rod Lock. Use

Teflon tape and/or pipe sealant on the threads. This

configuration will have slower response times.

Standard Configuration:

Attach the Quick Exhaust Valve to the Rod Lock. Use

Teflon tape and/or pipe sealant on the threads.

Cable Wire

Color

Valve

24 VDC Valve Pin

DIN Connector

for 964650 (Inch

NFPA Units)

Brown

+

1

White

-

2

Green

Ground Ground

DIN Connector for

964651 (Metric

ISO Units)

Black,L

+

1

Black,Labeled -

-

2

Green

Ground Ground

Table 3

Optional Solenoid Valve Specifications

Ports Part # Voltage Power Resistance Current Cv

English 964650 24 VDC 4 W 145 ohms .17 A .25

Metric 964651 24 VDC 4.8 W 120 ohms .20 A .915

DANGER

Support the load before disengaging the

Rod Lock. Failure to support the load

could result in serious bodily injury.

CAUTION

24 VDC valve connector has a

suppression diode installed across the

coil. Observe proper voltage polarity or

connector damage will result.

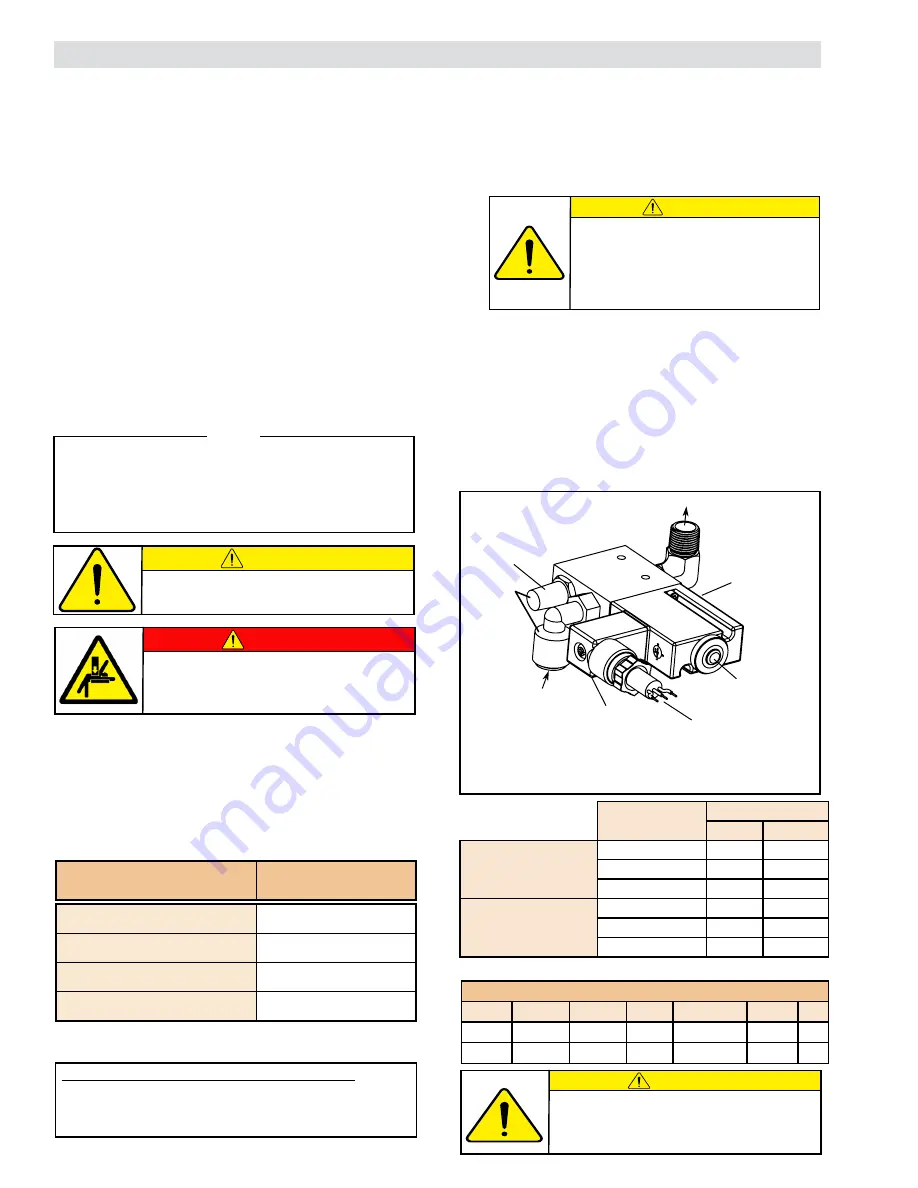

FIGURE 7

Optional Solenoid Valve #964651

(Metric Units)

Exhaust

Silencer

To Quick Exhaust, Brake

Air Supply

Tube Fitting

Manual Override*

(English Units)

DIN

Connector

Lead Wires

1/8 NPT (English Units)

1/8 BSPT (Metric Units)

- 1/4” O.D. Tube

(English Units)

- 6mm O.D. Tube

(Metric Units)

Manual Override*

(Metric Units)

CAUTION

The Rod Lock will disengage if you

depress the domed button at the top

of the Solenoid Valve (if air pressure

is applied). The LED will illuminate

when the Solenoid Valve is actuated

and the Rod Lock is disengaged.

With Optional Solenoid:

Mount the optional Solenoid Valve directly to the Rod

Lock using supplied fittings. Use Teflon tape and/or pipe

sealant on the threads. If the optional Solenoid Valve isn't

mounted directly to the Rod Lock, it is recommended

to mount a Quick Exhaust Valve near the Rod Lock

for better brake response times. Refer to

Figure 7

.

Table 2

NOTE:

Align the air inlet ports in the down position to

allow condensation to drain out of the air chamber.

2. Attach the air supply line to the air inlet, the quick

exhaust valve, or the solenoid valve, depending on

configuration selected in

Step 1

.

3. If using optional solenoid valve, attach DIN Connector

cable to valve by pressing DIN Connector onto valve

power pins and tightening DIN Connector fastener.

Then connect DIN Connector cable wires, using

Table

2

, to the appropriate power supply, see

Table 3

.

Optional Solenoid Valve #964650

(English Units)

Quick Exhaust Valves Air Pressure Ratings:

8 Bar [120 PSIG]

Max

(All Q.E. Valves)

0 Bar [0 PSIG]

Min

(English Q.E. Valve)

3 Bar [44 PSIG]

Min

(Metric Q.E. Valve)

Fittings are

configured

differently

on Metric

Solenoid

Valve.

See Sales

Drawing.

Rod Lock Unit Size

Quick Exhaust Valve

Part Number

Size 150-, 200- & 250-

NFPA Inch Units

945100 (.125-27 NPT)

Size 032-, 040-, 050- & 063-

Metric ISO Units

945127 (.125-28 BSPP)

Size 325-, 400-, 500-, 600- & 800-

NFPA Inch Units

945125 (.250-18 NPT)

Size 080-, 100- & 125-

Metric ISO Units

945128

(.250-19 BSPP)

BSPP ports accept BSPP or BSPT fittings of the same size.

ISO-G and BSPP are the same thing.

*

ROD LOCK AIR CONNECTIONS (Does not apply to customer cylinder)

The Nexen Rod Lock is equipped with a NPTF or BSPP

(ISO-G) port for the air inlet. Route clean air, using soft or

hard lines, supplying at least 4.1 bar [60 psi] to facilitate

full disengagement.

NOTE: Install the valve in close proximity to the Rod

Lock unit for faster engagement and disengagement.

Higher air pressures will also speed the disengagement

time, but do not exceed 8.0 bar [120 psi] air pressure.

The Nexen Rod Lock is equipped with a port for the internal

vent (filters are included with most models). If the air quality

around the application is poor, route the vent of the Rod

Lock to a more suitable area, or use a filtered breather.

Contact Nexen for available components.

NOTE: Clean air is important for proper Rod Lock

functioning. Debris inside the Rod Lock may inhibit

performance and/or shorten the life of the product.