9

FORM NO. L-21699-B-1120

OPTIONAL OPERATING MODE SENSOR(S)

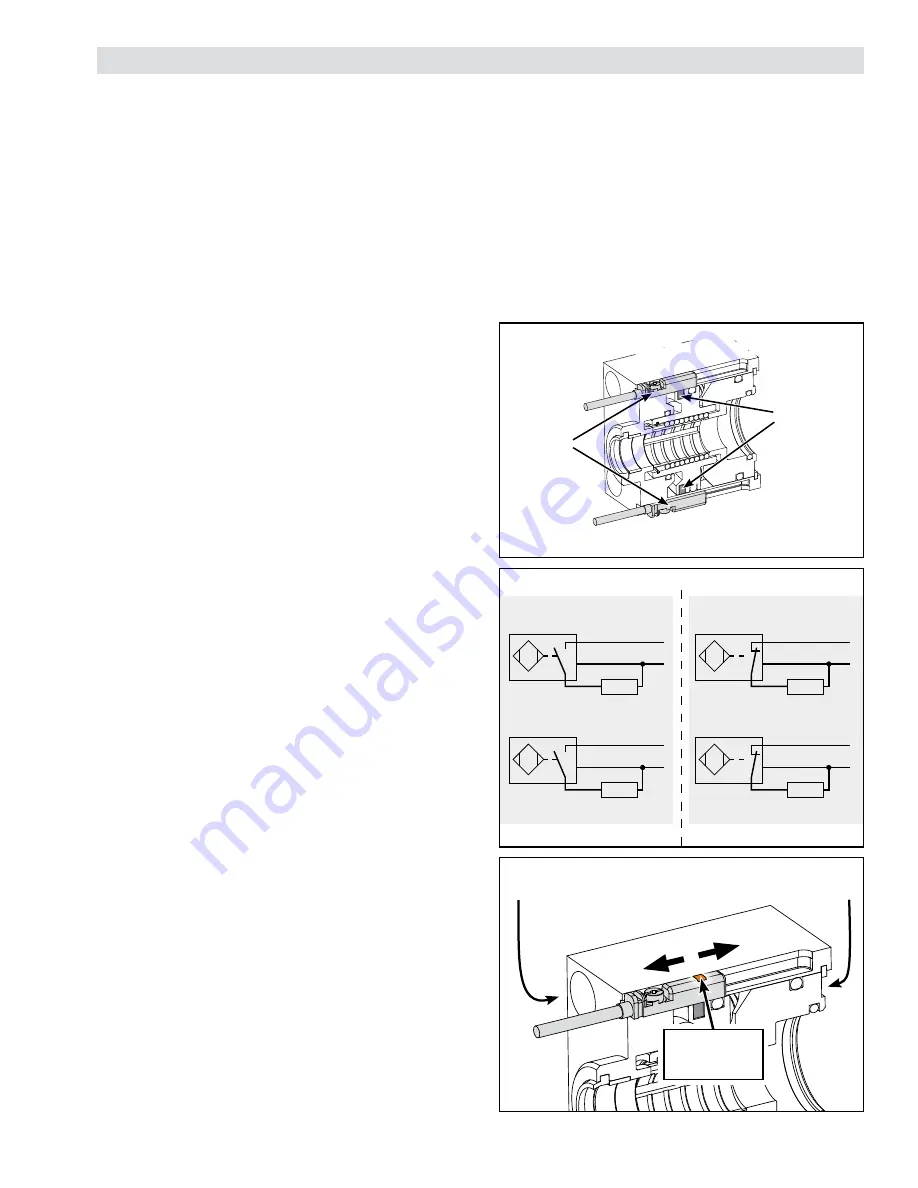

Nexen’s Magnetic Proximity Sensors are available to

gather operational data from the Rod Lock. The Safety

Rated RLSSB can be equipped with one or two T-slots

for sensor mounting.

These sensors may be used by system manufacturers

to gain higher safety category ratings per ISO 13849-1.

Rating of the safety function is the responsibility of the

system manufacturer.

Each Proximity sensor can be set up to sense one of the

following functions of the Rod Lock:

Disengagement Sensor Definition:

Sensor is activated when the rated air pressure is applied

and the piston moves to a disengaged position.

Engagement Sensor Definition:

Sensor is activated when the piston moves out of the

disengaged position into a position in which the clamp

collar constricts on the rod.

SENSOR WIRING

Nexen’s Magnetic Proximity Sensor is available in two

modes, see

Table 2

. System manufacturer is responsible

for selecting appropriate sensor type for specified safety

application.

PNP Mode (Sourcing)

Normally Open (N.O.) or Normally Closed (N.C.) PNP

type Sourcing Output available, see

Figure 5

. Typically

matched with a PLC Sinking Input.

NPN Mode (Sinking)

Normally Open (N.O.) or Normally Closed (N.C.) NPN type

Sinking Output available, see

Figure 5

. Typically matched

with a PLC Sourcing Input.

SENSOR INSTALLATION AND SETUP

Note: Validate sensor functionality in application, including

possible temperature range.

The Rod Lock can be equipped with one or two magnetic

proximity sensors. If two sensors are used, they can be

configured to detect redundant or individual engaged and

/ or disengaged states. If sensors are setup for redundant

detection, the sensor states should always match. If

sensors are setup for individual, opposing detection, the

sensor states should always be opposite. To ensure proper

operation, compare the expected state to the measured

state. Once installed on the rod, Nexen recommends

checking the positioning of the sensor for proper switching

location.

Wire magnetic sensor and insert cable clip into t-slot per

the instructions included with the sensor(s). Provide power

to sensor, and complete the following:

Sensing Disengagement Position:

1. With rod lock on rod, supply air pressure to the rod

lock so it is disengaged.

2. Install sensor as shown in

Figure 6

. Start with sensor

positioned closest to the

back

of the rod lock, past the

sensing target. Slide the sensor towards the

front

end

of the rod lock until LED is lit. Once the LED is lit, move

sensor a small amount further into sensing target.

3. Use a standard flat-head screwdriver or 1.5mm allen

wrench to turn the screw and fix the sensor in the t-slot.

4. Cycle air pressure to ensure the LED is lit only when

release air pressure is supplied to the rod lock.

BK

BU

-

BN

+

LOAD

NPN Mode (Sinking)

NPN Mode (Sinking)

PNP Mode (Sourcing)

BK

BU

BN

LOAD

PNP Mode (Sourcing)

BK

BU

BN

BK

BU

BN

LOAD

LOAD

0 VDC

10-30 VDC

-

+

0 VDC

10-30 VDC

-

0 VDC

+

10-30 VDC

-

0 VDC

+

10-30 VDC

Figure 5

Sensor Wiring

Figure 4

Locking

Mode

Sensor(s)

Sensing

Magnet

Note: Safety Rated Units may have

one or two sensor slots.

Sensing Engagement Position:

1. With rod lock on rod, remove air pressure to the rod

lock so it is engaged.

2. Install sensor as shown in

Figure 6

. Start with sensor

positioned closest to the

front

of the rod lock, before

the sensing target is reached. Slide the sensor

towards the

back

end of the rod lock until LED is

lit. Once the LED is lit, move sensor a small amount

further into sensing target.

3. Use a standard flat-head screwdriver or 1.5mm allen

wrench to turn the screw and fix the sensor in the t-slot.

4. Cycle air pressure to ensure the LED is lit only when

air pressure is removed from the brake.

Figure 66

(Engagement)

(Disengagement)

Sensor Adjustment Direction

Back

End of

Rod Lock

Front

End of

Rod Lock

LED Light

LED Light

on Sensor

on Sensor

Note: Ferrous Materials in Close Proximity

may interfere with sensor function.

Normally Open:

Normally Closed: