- Installation instructions for supplementary outriggers -

Via Mediterraneo, 6 - 42022 - Boretto - Reggio Emilia - Italy

Tel. +39 - 0522-96 30 08 - Fax +39 - 0522-96 30 39

info@maxiliftcrane.com

- 35 -

18.3 - Regular checks

18.3.1 For all the models

Weekly:

-

Check for presence of oil leaks from hoses / pipings and fittings, if any, find out and remove their

causes.

-

Check for damages or wear on hoses and piping.

-

Check the locking pins and safety latches: They must be efficient and perfectly working. If bent,

broken, damaged or missing of any item, they must be immediately replaced or repaired at authorized

workshop.

-

Check integrity and efficiency of the devices supporting and driving the hoses whilst extending.

18.3.2 Stabilizer models “ML”, “0”, “1”, “2”, “3”

-

Weekly:

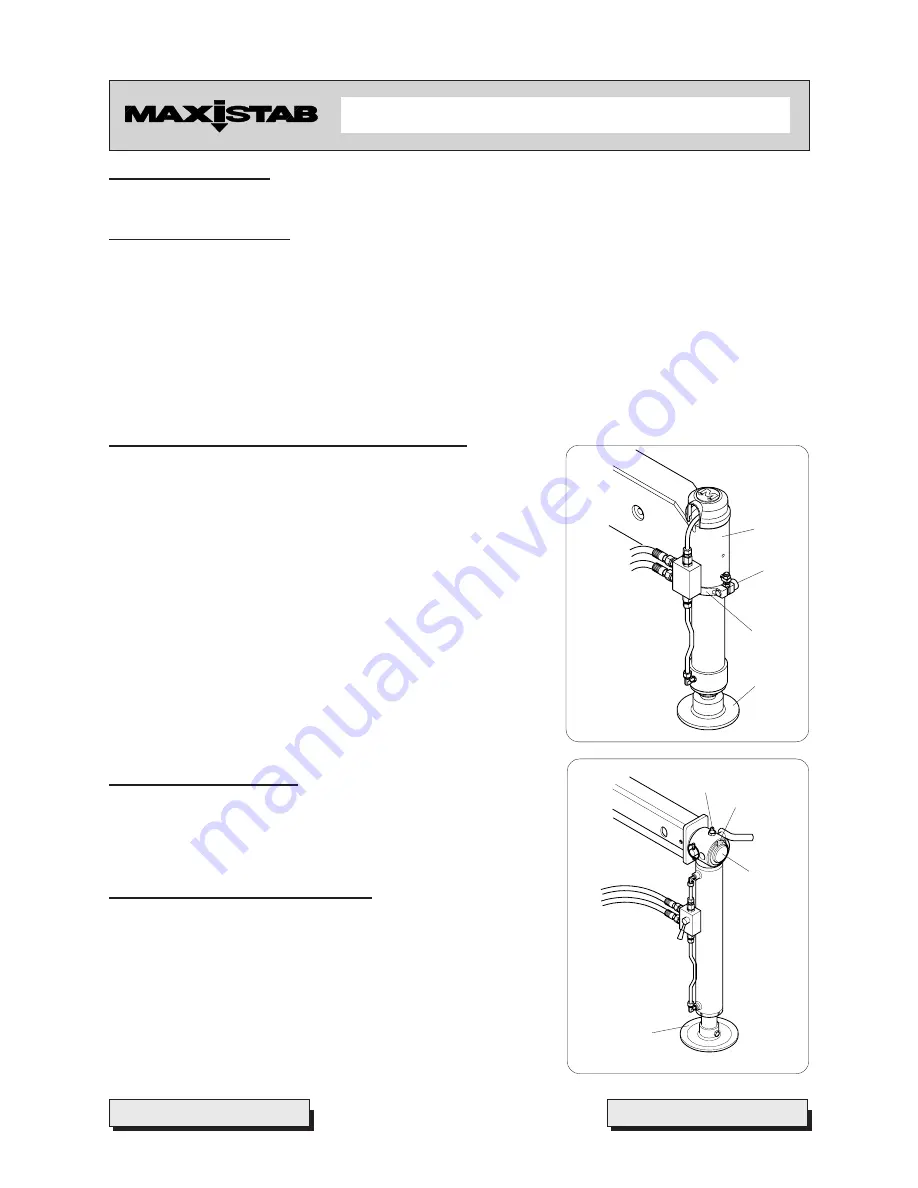

Carry out a visual checking making sure that the cylinders

did not move upwards or that, with cylinders in transport

position, there is no clearance between the locking collar and

the sleeve; in case one of the above situations occurs, have

screw tightening checked by an authorized workshop.

(Pict. 39)

-

Yearly:

Have screw tightening checked by an authorized workshop

and, if necessary, restore it tightening by torque wrench,

according to what shown in Tab. 1.

Each operation beyond what described has always to be approved

by

Next Hydraulics’

Technical Department, whom you have to

apply to for any clarification and further information required.

18.3.3 Tilting legs models

Quarterly:

Check that the pivot (1) and its bushing (2) are correctly greased. If

not, apply grease through the relevant grease nipple (3). (Pict. 40)

18.3.4 Foot plates on stabilizer legs

(Ref. picts. 39, 40 Pos.4)

Weekly:

Check that the bearing surface is plane, without damages nor

deformations. If not, replace with original parts.

1

2

Pict. 40

3

Pict. 39

4

4

3

1

2

- Use and maintenance manual -