4

1. Introduction

This manual contains procedures for installation, safety, operation, and maintenance of a 5-ton desktop servo press-fit

machine LPM3.

1.1. Safety

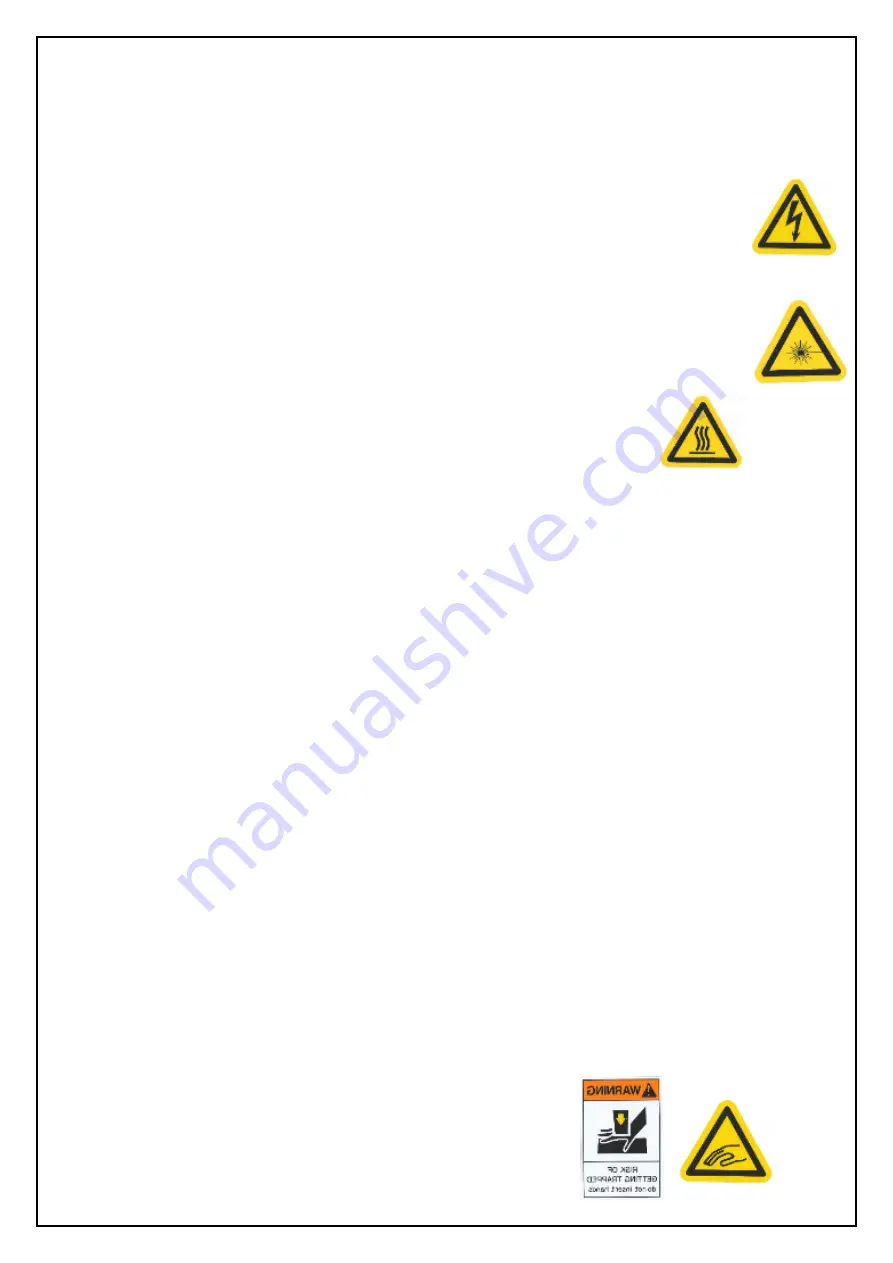

1. Electrical-

The power wiring of three-core cable connected to the power box needs to include a grounding

wire to prevent leakage currents from affecting people. The cross-sectional area of this single core

must be greater than 3.5mm². A fixed retaining ring is installed on the main power box and

the distribution box door to prevent personnel from the danger of electric shock.

2. Protection of eyes and ears-

Operator should wear eye protect when operating or maintaining the machine. The noise generated

by the machine is not excessive over 70 dB. It is based on your own discretion to wear ear

protection or not. And please be careful not to look directly at the laser marking instrument.

3. Temperature-

Please do not touch the motor which may generate high temp. 30~50°C.

4. EMO, Emergency Off buttons-

The emergency off button is installed on both sides of the front of the table and is clearly marked. When they were

pressed, you must pull out of the button to release from the lock state. The EMO loop is a hard interlocked

connection that is only released when the EMO buttons are released. The motor's control circuit is cut off when the

EMO buttons are pressed. After all safety and conditions are met then EMO activation signal is output from the

computer.

1) The Acroloop servo controller watchdog signal is true and is false when the controller detects a problem.

2) The Acroloop servo controller PLC output - servo controller has an internal program to monitor servo operation

and disconnect the EMO circuit when a problem is detected.

3) Motor overload relay, which is a temperature-sensitive motor overload protection device, monitors the motor

over-current condition. If the motor current is consumed for a long time, it will automatically cut off and

re-conduct after about 3 minutes of cooling.

5. Release emergency operation-

After confirming the emergency stop condition and eliminating it, release it under the safe condition, pull up the

emergency off button and start the motor power.

6. Two-handed start switch-

The two-handed start switch is located on the left and right sides of the button box in front of the XY-TABLE.

The button is a flat button with no protrusion. In order to prevent body or other inadvertent contact, each switch

is separately connected, and the two switches must be pressed at the same time to start the machine operation.

7. Safety handle-

The safety handle is placed on the upper right side of the machine. When the handle is pressed down, the machine

can be started with the two-hand button. Please push the handle up when replacing the fixture. The operating space

can be increased for safety concern. During the pressing process, when the equipment is down and someone is in

danger, please push back the handle for emergency stop. In case of power failure, the product under the pressing

head can also be taken out.

8. Safety cover-

All covers must be positioned before pressing, including front and rear

panels, top screw cover and other protective parts.