TRACE

MATE II-CTR

1.1

Product Overview

Introduction

The TraceMate II-CTR solid state heat tracing control is

an electronic thermostat designed to maintain two

seperated heaters at their respective desired setpoint

temperatures. It is suitable for use with mineral-insulated,

self-regulating or constant-wattage cable in applications

such as freeze protection, process control and instrument

tracing. The TraceMate II-CTR is intended for indoor or

outdoor installation in ordinary or class 1, division 2

hazardous locations.

TraceMate II-CTR offers many advantages over other

heat tracing control schemes, which generally use some

combination of mechanical thermostats, custom-built

panels or programmable controls to provide control,

monitoring and alarm functions. Wiring costs are mini-

mized by mounting the control in close proximity to the

heat tracing cable and pipe. A NEMA 4 enclosure and

wide temperature range electronic components are used to

make mounting possible in most locations. Temperature

sensing of each heater is achieved by mounting a 100 ohm

platinum (DIN 43760) RTD sensor on the pipe. Heater

current is controlled by a solid state switch rated 30A.

The temperature setpoint and other setpoints are digital

for fast non-ambiguous setting over a wide range. Instant

system information such as pipe temperatures, heater

currents, ground fault currents, and heater on/off & alarm

status can be seen on the LCD display mounted on the

door of the enclosure. Maximum system reliability is

obtained from a comprehensive alarm package which

includes LCD display messages and LED indicators for

quick fault identification and a ground fault trip to

minimize fire hazards.

By combining the control, system monitoring and testing

requirements of a heat trace control system into a general

purpose control, the TraceMate II-CTR makes it possible

to significantly upgrade systems at low installed cost. In

addition, it is very flexible in its application to adapt to

specific user requirements.

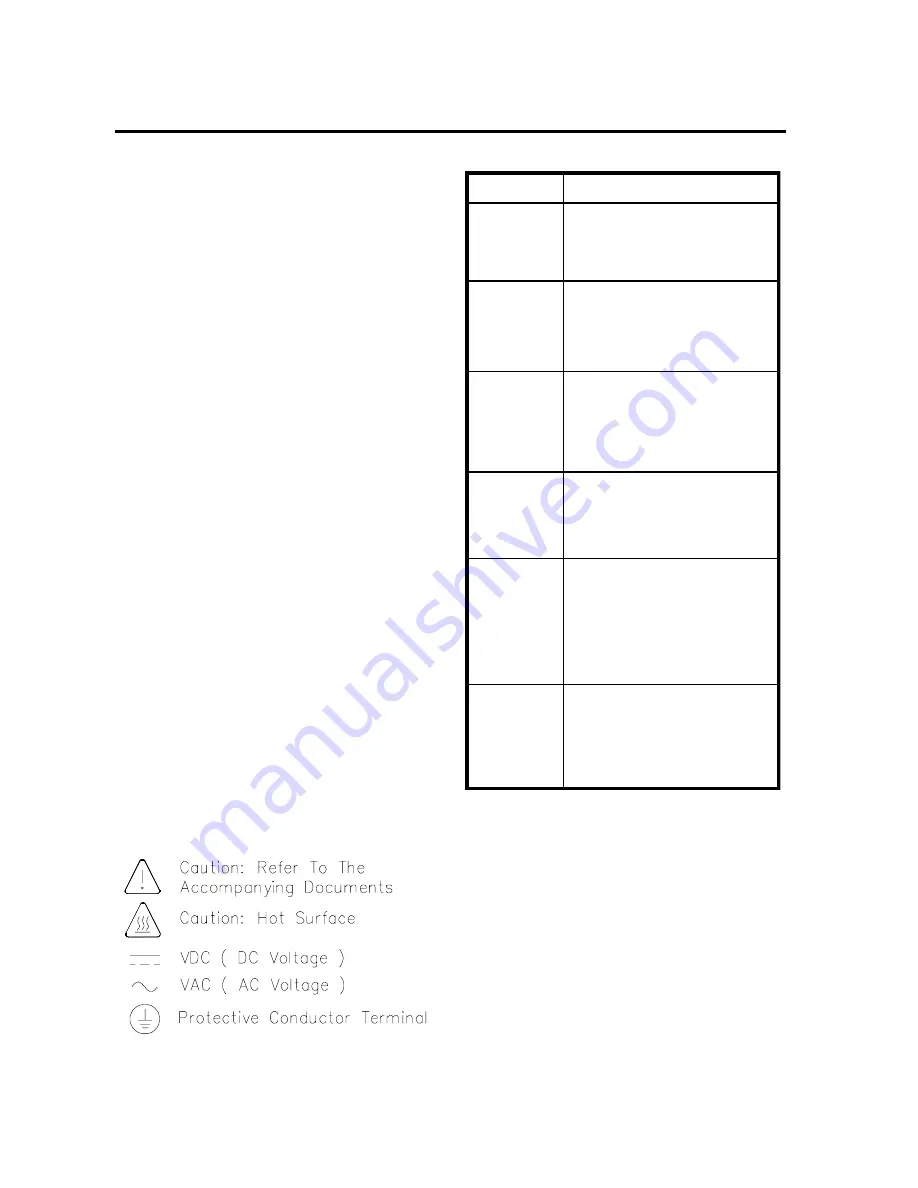

Conventions

The following conventions are used in this manual:

Features and Benefits

Requirements

TraceMate II-CRT Features

Temperature

Control

*

*

*

*

0-511°C/0-511°F setpoint

Non-ambiguous, digital temperature

setpoint

100 ohm platinum RTD sensor

3-wire, lead resistance compensation

System Fault

Alarms

*

*

*

*

*

*

Breaker left off or tripped

Heater continuity or low current

Ground fault trip

Low temperature

High temperature

Broken sensor

Early Warning

*

*

*

Tracecheck exercises dormant

systems every 24 hours for early

warning to prevent shutdowns

LCD display messages and LED

indicators show cause of alarms

Separate fail-safe local and remote

alarms

Remote

Monitoring

*

*

*

*

DC or AC alarm output for PLC or

remote alarm indication

Form C alarm dry contact output

alarm indication

RS232 communication port

16X1 LCD display

Hazardous/

Ordinary Area

Mounting

*

*

*

*

CSA approved for ordinary or Class

1, Division 2, Grps A,B,C,D

hazardous area

-40° to +50°C operating range

30 amps @120/208~240/277VAC

rating

Weatherproof, Nema-4 enclosure

Easy retrofit replacement for

mechanical thermostat

Low Installed

Cost

*

*

*

*

Competitively priced

Self contained, no control panel to

build

Ground fault trip eliminates expensive

ground fault circuit breaker

Standard model simplifies spare

parts stocking