TRACE

MATE II-CTR

Chapter 3 APPLICATIONS

3.1

Mechanical Thermostat Replacement

Mount the control unit near the pipe being traced in a

location with easy access. Replace the thermostat capil-

lary tube with an RTD mounted on the pipe and connect

the existing heater and power wires to the TraceMate II-

CTR as shown in Figure 3.1. A 16x1 LCD display is

mounted on the door of TraceMate II-CTR. Instant system

measurements such as pipe temperatures, heater currents,

ground fault currents, and heater on/off status can be seen

on the display. Also, the alarm status of each heater and

their causes are shown on the display. If control power is

not available, the LCD display will go off.

Advantage of this scheme over mechanical thermostats is:

easy setpoint adjustment, ground fault current protection,

early warning of system faults with TraceCheck system

exercising every 24 hours and rapid fault diagnosis in the

event of a problem.

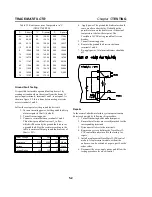

Remote Zone Alarm

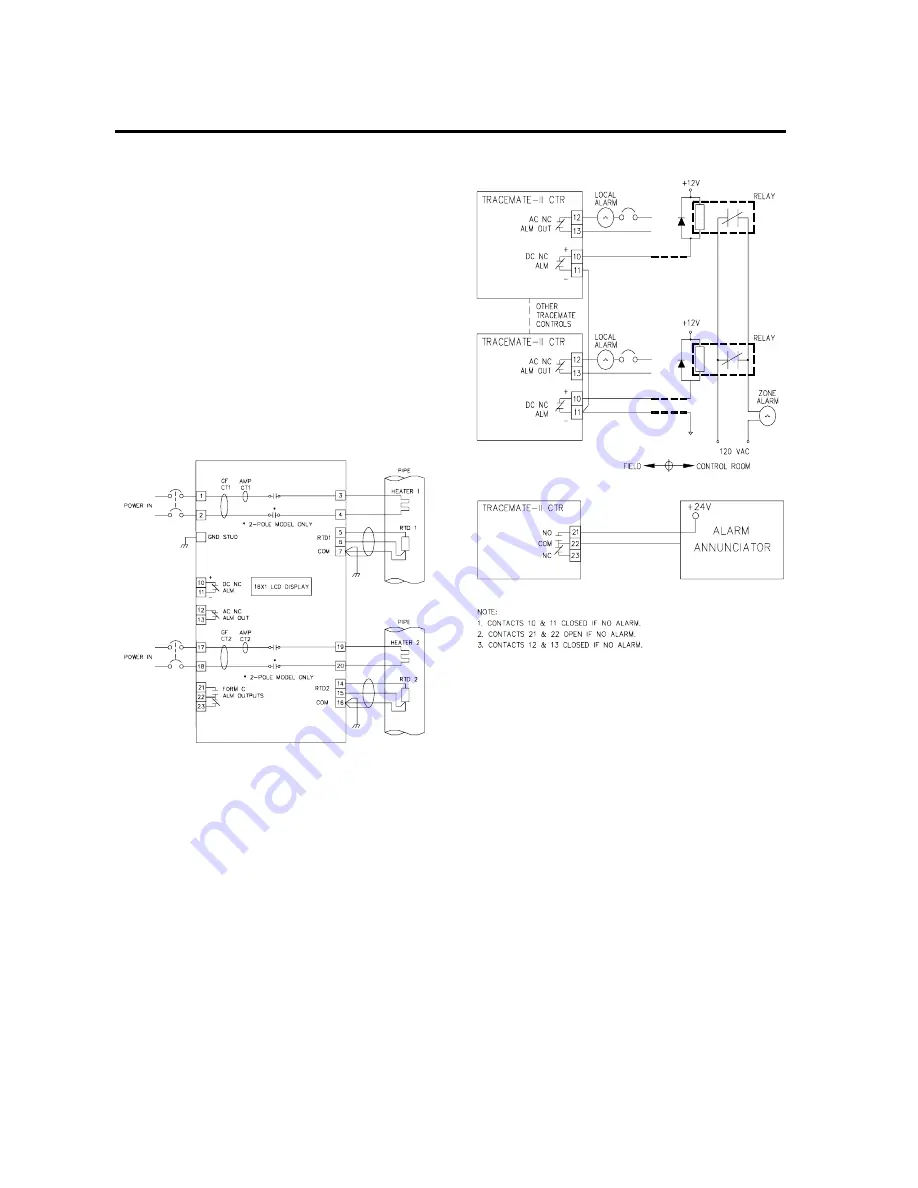

If a remote alarm is required, a number of TraceMate II-

CTR control alarms can be connected to give a remote

zone alarm indication in a control room as shown in

Figure 3.2. Once the alarm goes on, maintenance

personnel can be dispatched to the area. The heat trace

point with a problem can be identified by the alarm

messages on the LCD display. For a fast diagnosis and

repair, the alarm message on the display and the status

LED indicators in the TraceMate II-CTR identify the

exact nature of the problem. This simple connection

minimizes control room panel space, allowing a few LCD

displays and indicators to cover a complete plant.

Alarm Annunciator

If an alarm annunciator or programmable controller is

available, terminal 21, 22 & 23 can be used as a low cost

digital interface. These terminals are form C dry con-

tacts. A separate voltage source must be connected across

these terminals as shown in Figure 3.2 for the annuncia-

tor to sense the alarm logic.

Local Alarm

A local visual alarm indicator can also be connected to

the isolated AC alarm output terminals 12 and 13 as

shown in Figure 3.2.

Switching Requirements

Four different TraceMate II-CTR models are available to

accommodate different power rating of electric heat

trace. TM-2SIH1-RTD is rated single-pole 120VAC@

30A; TM-2SIH1-RTD-240V is rated single-pole

240VAC@30A; TM-2DIH2-RTD-208~240V is rated

dual-pole 208~240VAC@30A; TM-2SIH1-RTD-277V is

rated single-pole 277VAC@30A.Refer to Figure2.2

Typical Wiring Diagram for power and heater wiring.

Figure 3.1 Thermostat Replacement

Figure 3.2 Alarm Wiring