5

SAFETY INFORMATION

SEVERE PERSONAL INJURY AND PROPERTY DAMAGE CAN RESULT FROM IMPROPER INSTALLATION

OR ASSEMBLY. READ THE FOLLOWING WARNINGS BEFORE BEGINNING:

WARNINGS:

1.

Do not use this product for any application other than those specified by Nexus 21.

2.

Do not exceed the weight capacity. This can result in serious personal injury or damage to the equipment. It is the installer’s

responsibility to ensure that the total combined weight of all attached components does not exceed that of the maximum

figure stated.

3.

Follow all technical specifications and instructions during the installation.

4.

Only use attachments/accessories specified by the manufacturer.

5.

Close supervision is necessary when this system is being used by, or near, children, or disabled persons.

6.

It is the responsibility of the installer to warn all potential users of the dangers of interfering with the mechanism during

operation.

7.

Read all technical instructions fully before installation and use. It is the installer’s responsibility to ensure that all

documentation is passed on the users and read fully before operation.

8.

Failure to provide adequate structural strengthening, prior to installation can result in serious personal injury or damage to

the equipment. It is the installer’s responsibility to ensure the structure to which the Lift System is affixed can support four

times the weight of the system.

9.

Risk of electric shock. Do not attempt to open the Control Box.

10.

To reduce risk of fire or electric shock, do not expose parts to rain or other liquids.

11.

Protect the power cord from being walked on or pinched.

12.

Keep all documentation.

13.

Heed all warnings.

14.

Clean only with a dry cloth.

15.

Refer all service questions to Nexus 21 if the system does not operate normally.

Nexus 21 disclaims any liability for modifications, improper installations, or installations over the specified weight range. Nexus 21 will not be liable for

any damages arising out of the use of, or inability to use, Nexus 21 products. Nexus 21 bears no responsibility for incidental or consequential damages.

This includes, but is not limited to, any labor charges for the servicing of Nexus 21 products performed by anyone other than Nexus 21.

Nexus 21 intends to make this and all documentation as accurate as possible. However, Nexus 21 makes no claim that the information contained herein

covers all details, conditions or variations, nor does it provide for every possible contingency in connection with the installation or use of this product. The

information contained in this document is subject to change without prior notice or obligation of any kind. Nexus 21 makes no representation of

warranty, expressed or implied, regarding the information contained herein. Nexus 21 assumes no responsibility for accuracy, completeness or

sufficiency of the information contained in this document.

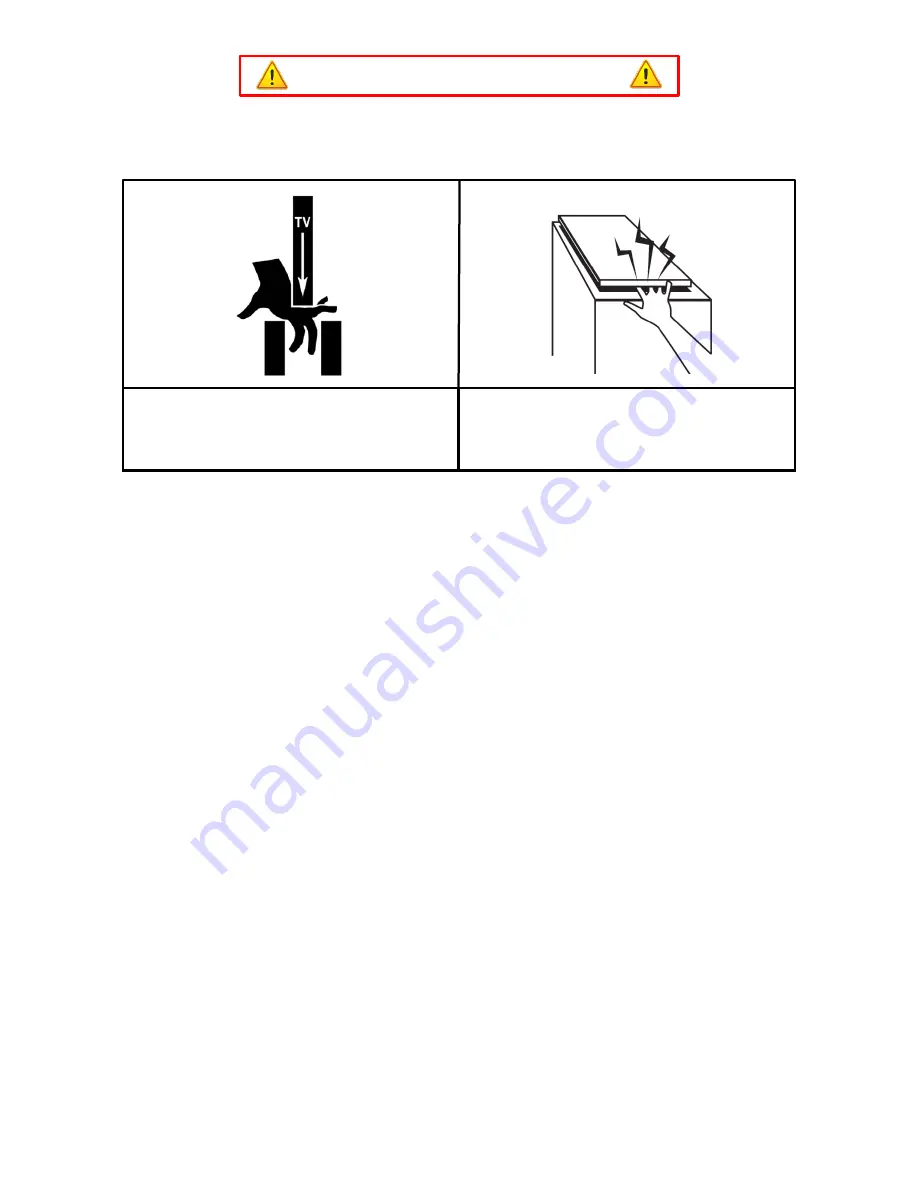

CABINET LID HAZARD

TV HAZARD

CAUTION:

Avoid contact with the TV and Lift System during

operation. Use with caution.

CAUTION:

The cabinet lid must be installed as described in the

instructions, using the Steel Threaded Tapered Pins. Installing

the cabinet lid in any other fashion will create hazardous pinch

points that can cause serious personal injury.

Summary of Contents for L-45ens

Page 1: ...TV Lift System Model L 45ens Installation Instructions ...

Page 2: ...2 ...

Page 27: ...27 Supplemental Page A L 45ens Installation Dimensions ...

Page 28: ...28 Supplemental Page A L 45ens Installation Dimensions Page 2 ...

Page 30: ...30 Supplemental Page C Connect the Lift to Home Control System ...

Page 31: ...31 ...

Page 32: ...32 866 500 5438 ...