Summary of Contents for XL-85s

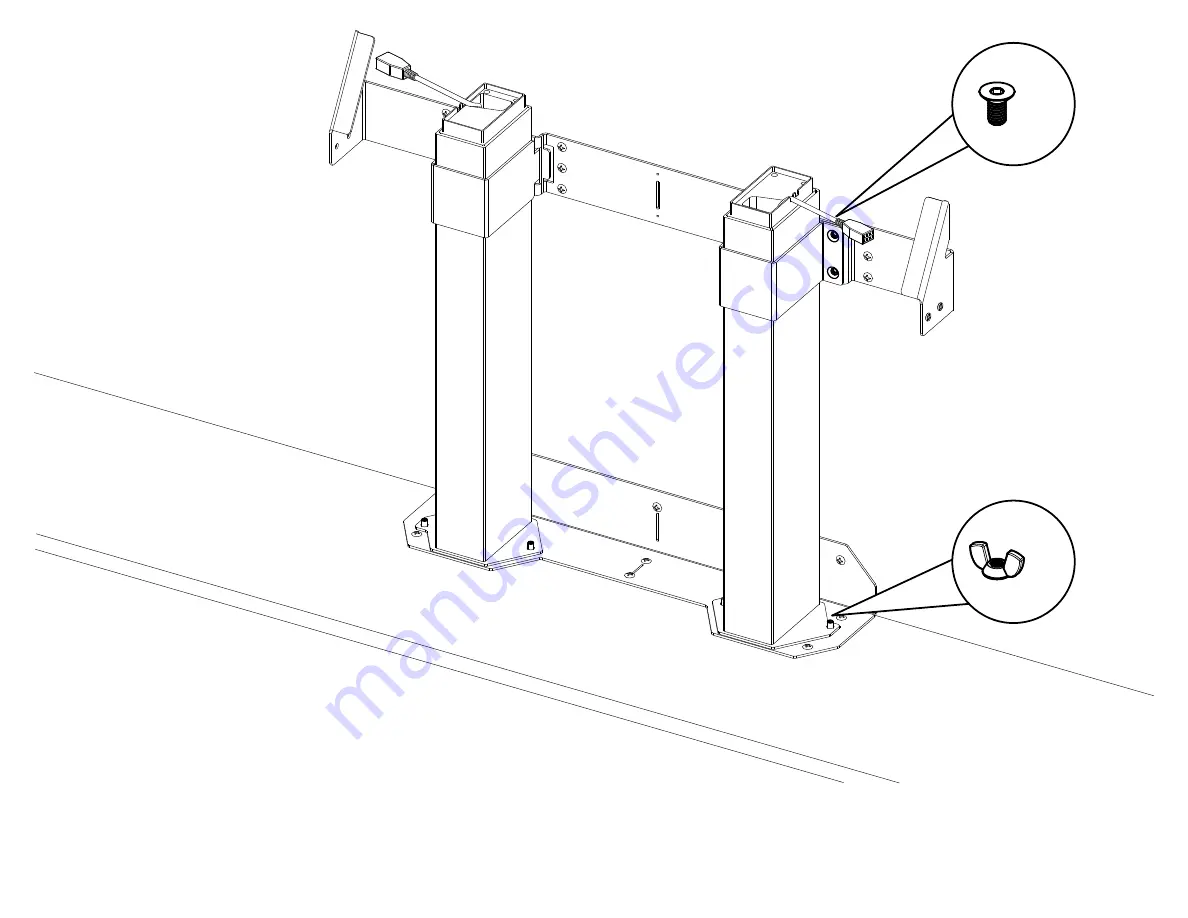

Page 1: ...Installation Manual for L 85s XL 85s...

Page 2: ......

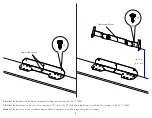

Page 14: ...Lower Cable Management 14...

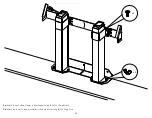

Page 19: ...Upper Actuation System 19...

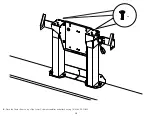

Page 24: ...Upper Cable Management 24...

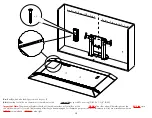

Page 51: ......

Page 52: ...1 888 981 9919 www nexus21 com...