2

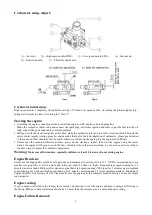

Carburetor setup, adjust:

①—

Air inlet

;

②—

High speed needle(HSN)

;

③—

Low speed needle(LSN)

;

④—

Inlet nozzle

;

⑤—

Suction nozzle

;

⑥—

Throttle control arm

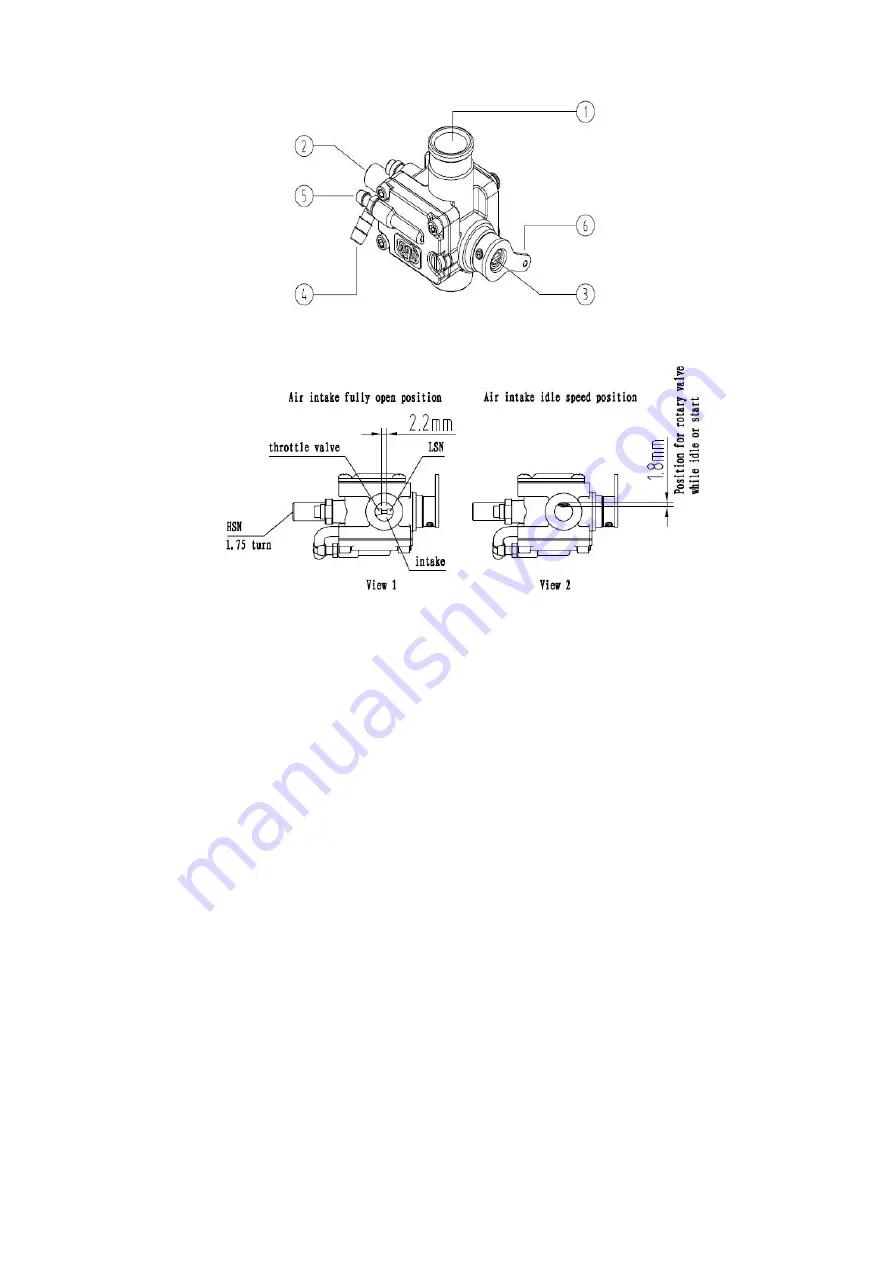

Carburetor initial setup:

High speed needle

:

Completely closed before exiting 1.75 turns; Low speed needle

:

According the initial setup factory ;

Idling start time the air inlet: According the “View 2”

Starting the engine:

1. According the engine connection method, install the engine on RC airplane and lock propellers.

Made the carburetor initial setup and connect the spark plug, electronic ignition and sensors, put the fuel into the oil

tank, connect the power and radio control equipment.

2. Will power off the electronic igniter at this time, make the carburetor inlet port in a fully closed position. Through the

motor starter rapidly rotating propeller engine make the fuel in the tank inhalation of carburetor, please pay attention

to the suction of fuel should not be too much, otherwise will drown the spark plug, the engine start difficult.

3. Please open the carburetor throttle air inlet, power on the electronic igniter, then start the engine using the motor

starter, the engine will begin to work, the fans will adjust the carburetor according to your own need. According to

the above steps to adjust the carburetor adjustment.

Warning:

Make sure all bystanders, especially children, at least 30 feet away from rotating engine.

Engine Break-in:

Please use the high quality synthetic oils, gasoline and machine oil’s mixing ratio is 25:1. NGH is recommended to use

smaller size propellers at first break-in and follow-up about 10 times in flight. Keep medium speed running for 15

minutes (no more than 4000rpm) after started engine, then high speed running (7000 rpm) for 3 minutes, again medium

speed running for 5 minutes, high speed running for 3 minutes, reciprocating 3-5 times complete break-in. Breaking in

engine carefully will increase its life. Please make sure the engine got the complete break-in before you use the larger

load propeller.

Engine cooling:

If your engine is installed in the fairing, there must be air entering to cool the engine and ensure enough air flowing in

the faring. Reference data: Outlet area should be 3-5 times than the entrance area to ensure adequate cooling.

Engine Failure Removal: