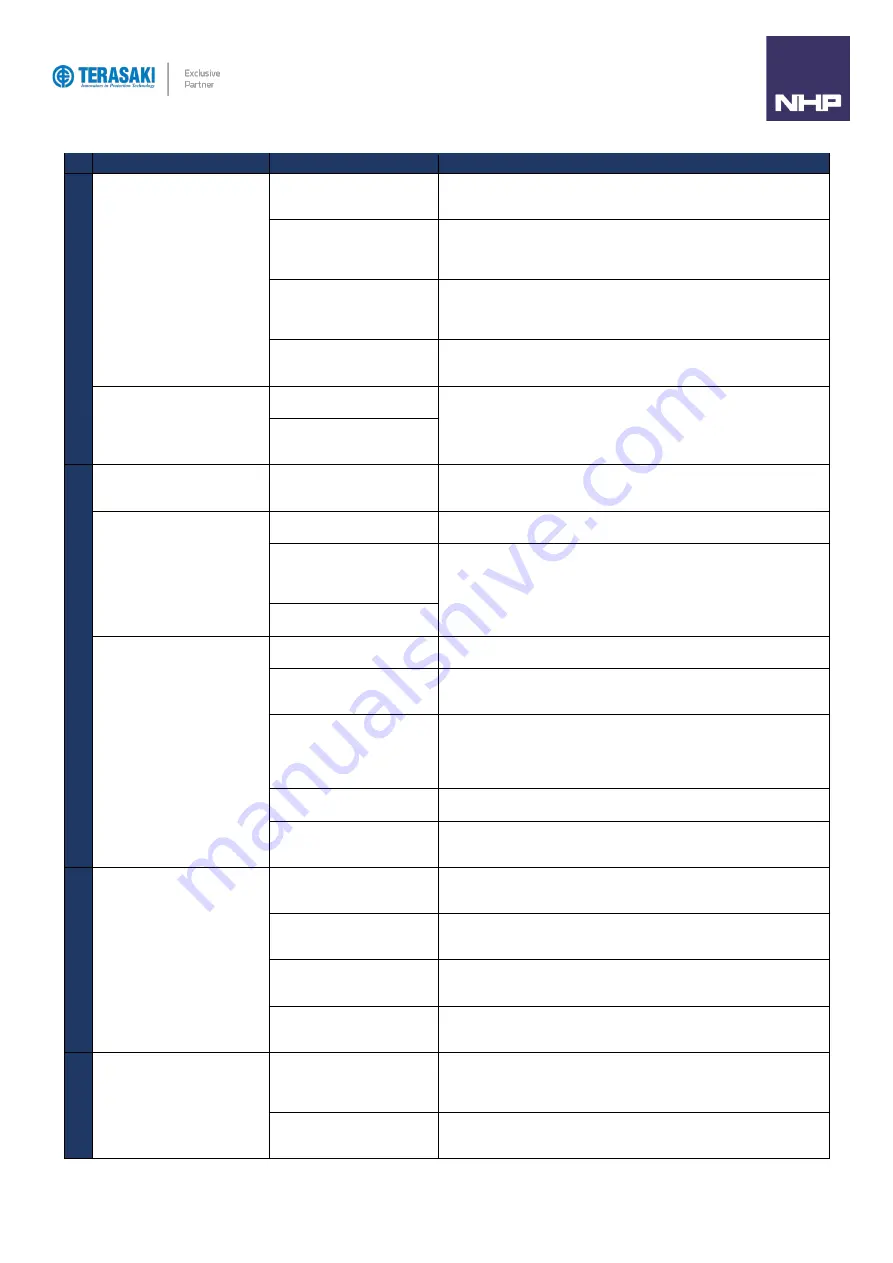

Troubleshooting

105

TemBreak

PRO

P_SE-UM-001-EN

– V1.2.0

Problem description

Possible cause

Remedial advice

4

OCR over temperature alarm

(Internal OCR temperature > 105°C)

Excessive ambient temperature.

Verify ambient temperature surrounding the MCCB do not exceed the maximum rated

ambient temperature range (-25°C...+70°C)

Loose terminal screw or conductor

connecting screw.

Verify and correct any loose connections to load and line terminals.

Refer to torque and connection requirements in TemBreak

PRO

P_SE Installation

Instructions supplied with MCCB

Increased contact resistance,

loose internal connection or

contact failure.

Replace MCCB

High proportion of high frequency

distortion in load current.

Decrease distortion content of load circuit

5

Abnormal voltage on load side

Excessive wear of contacts

Replace MCCB.

Foreign matter interfering with

contacts or contact surfaces

6

Failure in ON position

Reset operation not conducted

after tripping operation.

Perform reset operation.

7

Failure in RESET position

UVT not energised

Apply voltage to UVT

Circuit breaker service life ended

due to large number of switching

cycles using SHT or UVT

Replace MCCB

Fault of tripping mechanism

8

Nuisance tripping while rated current

not reached

Vibration and/or shock

Dampen vibration of MCCB and review installation requirements

High proportion of high frequency

distortion in load current.

Decrease distortion content of load circuit

Electromagnetic induced

interference (from nearby

conductors or external radio

sources)

Review nearby sources of conducted and radiated emissions (e.g. radio sources,

high-speed switching devices including variable frequency drives)

Excessive surge

Isolate and mitigate surge source (e.g. surge protection devices)

Erroneous connection of control

circuit for SHT or UVT

Verify control wiring and supply to SHT and UVT

9

Nuisance tripping due to starting

current

Excessive inrush starting current

due to load type

Review INST and STD protection settings for load type where applicable

Switching operation of star-delta

motor starter, incorrect wiring

Verify and correct any issues with star-delta starter wiring with respect to the motor

windings and phase sequence. Refer to motor and/or starter manufacturer

Short-circuit in motor (e.g.

windings, starter circuit)

Verify and correct any issues with motor wiring. Inspect and verify motor winding

insulation. Refer to motor manufacturer

Erroneous connection of control

circuit for SHT or UVT

Verify control wiring and supply to SHT and UVT

10

No trip at pickup current

Failure in selectivity/coordination

with upstream circuit breaker or

fuse

Review selectivity/coordination study and protection parameters of each device

Incorrect protection settings

Review enabled protection settings ensuring correct pickup current and time-delay for

load type. (e.g. LTD, STD, INST pickup currents and time delays)

Summary of Contents for Terasaki TemBreak PRO P SE Series

Page 106: ...106 TemBreak PRO P_SE UM 001 EN V1 2 0 Annex A Dimensions P160 Dimensions...

Page 107: ...Annex A Dimensions 107 TemBreak PRO P_SE UM 001 EN V1 2 0 P250 Dimensions...

Page 108: ...Annex A Dimensions 108 TemBreak PRO P_SE UM 001 EN V1 2 0 P400 Dimensions...

Page 109: ...Annex A Dimensions 109 TemBreak PRO P_SE UM 001 EN V1 2 0 P630 Dimensions...

Page 111: ...111 TemBreak PRO P_SE UM 001 EN V1 2 0 Annex C I2t Let Through Curves P160_SE...

Page 112: ...Annex C I2t Let Through Curves 112 TemBreak PRO P_SE UM 001 EN V1 2 0 P250_SE...

Page 113: ...Annex C I2t Let Through Curves 113 TemBreak PRO P_SE UM 001 EN V1 2 0 P400_SE...

Page 114: ...Annex C I2t Let Through Curves 114 TemBreak PRO P_SE UM 001 EN V1 2 0 P630_SE...

Page 115: ...115 TemBreak PRO P_SE UM 001 EN V1 2 0 Annex D Peak Let Through Curves P160_SE...

Page 116: ...116 TemBreak PRO P_SE UM 001 EN V1 2 0 P250_SE...

Page 117: ...117 TemBreak PRO P_SE UM 001 EN V1 2 0 P400_SE...

Page 118: ...118 TemBreak PRO P_SE UM 001 EN V1 2 0 P630_SE...

Page 121: ...121 TemBreak PRO P_SE UM 001 EN V1 2 0 This page is intentionally left blank...