Step 22

: Fireman’s Pole Assembly

•

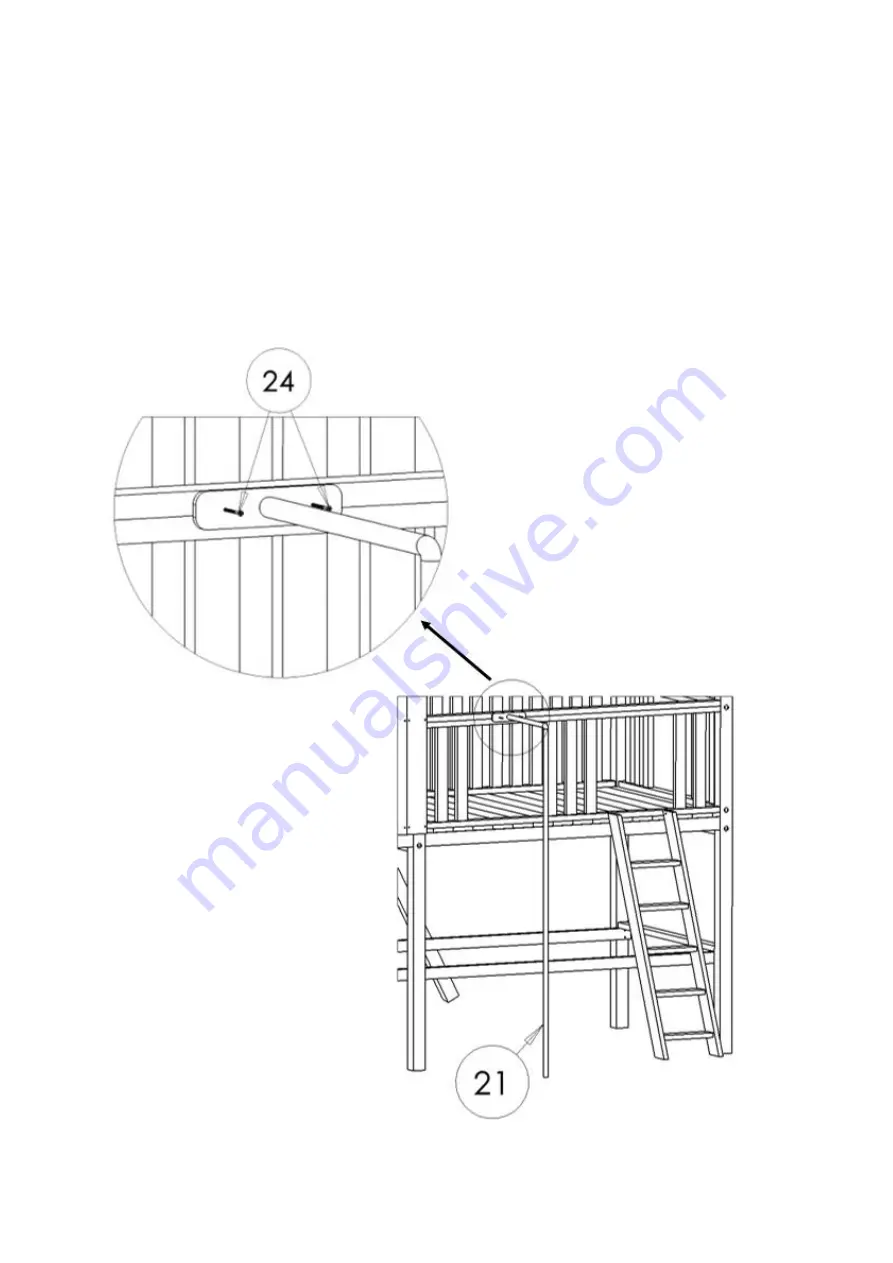

Place the fireman’s pole into its position and mark the position that it

will go into the

ground, which will be the centre of the railing and out the same distance as the turn in the

pole itself

•

Dig a hole about 10” deep and 10” in diameter

•

Place the fireman’s pole into the hole and cut off any excess length so that the pole ca

n be

secured into the top rail

•

Secure the climbing pole onto the top rail using 6x60 screws supplied

•

Concrete the pole into its place ensuring that it remains parallel to the tower posts

Summary of Contents for Hangout Climbing Frame

Page 1: ...Hangout Climbing Frame Instruction Manual ...

Page 6: ...16 3 6m x 3 x 1 5 2 17 1575mm x 3 x 1 5 5 18 Set of steps 1 19 Screw covers Approx 20 ...

Page 15: ...Step 5 Repeat steps 1 4 for the second half of the structure ...

Page 22: ...Step 12 Repeat steps 10 and 11 for each railing ...

Page 26: ... Repeat this for the three sides that are to be enclosed ...

Page 31: ......

Page 36: ...Step 26 Lower H Frame Supports Removal Remove the lower H frame supports from the tower ...