—

4

—

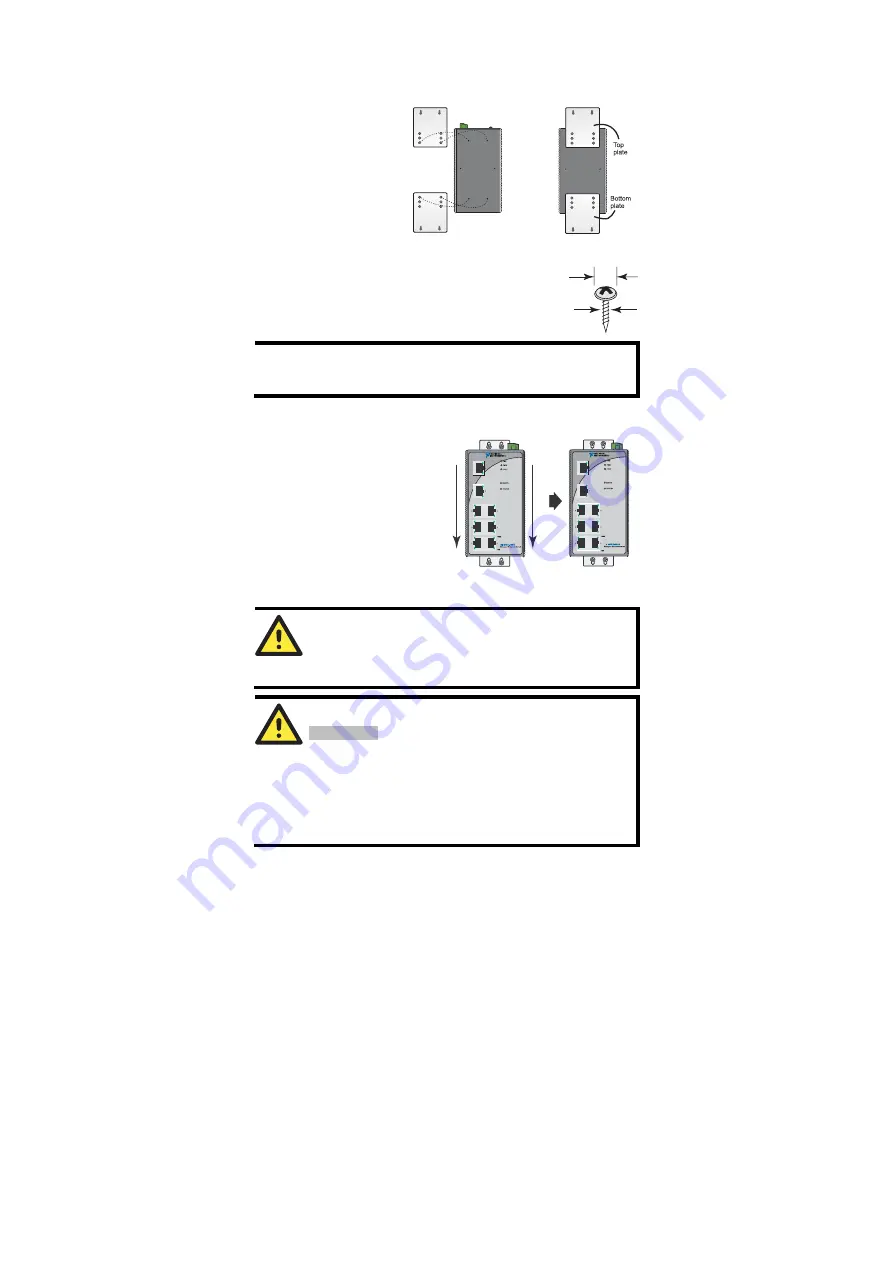

Wall Mounting (optional)

For some applications, you will find it convenient to mount the NI MES-3980

on the wall, as shown in the following figures.

STEP 1:

Remove the

aluminum DIN-Rail

attachment plate from the NI

MES-3980’s rear panel, and

then attach the wall mount

plates, as shown in the

figures at the right.

⇒

STEP 2

:

Mounting the NI MES-3980 on the wall requires 4 screws.

Use the NI MES-3980, with wall mount plates attached, as a

guide to mark the correct locations of the 4 screws. The

heads of the screws should be less than 6.0 mm in diameter,

and the shafts should be less than 3.5 mm in diameter, as

shown in the figure at the right.

6.0 mm

3.5 mm

NOTE

Before tightening the screws into the wall, make sure the screw head

and shank size are suitable by inserting the screw into one of the

keyhole-shaped apertures of the Wall Mounting Plates.

Do not screw the screws in completely—leave about 2 mm to allow room for

sliding the wall mount panel between the wall and the screws.

STEP 3:

Once the screws are fixed in

the wall, insert the four screw heads

through the large parts of the

keyhole-shaped apertures, and then

slide the NI MES-3980 downwards,

as indicated. Tighten the four screws

for added stability.

Wiring Requirements

WARNING

The power for this product is intended to be supplied by a Listed

Power Unit, with output marked LPS, and rated to deliver 12 to

45 VDC at a maximum of 600 mA.

WARNING

Safety First!

Be sure to disconnect the power cord before installing and/or

wiring your NI MES-3980. Calculate the maximum possible

current in each power wire and common wire. Observe all

electrical codes dictating the maximum current allowable for each

wire size. If the current goes above the maximum ratings, the

wiring could overheat, causing serious damage to your

equipment.