© National Instruments

|

2-3

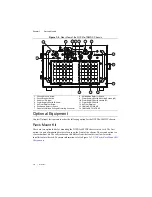

Figure 2-2.

NI PXIe-1082DC Vents

Chassis Ambient Temperature Definition

The chassis fan control system uses intake air temperature as the input for controlling fan speeds

when in Auto Fan Speed mode. Because of this, the chassis ambient temperature is defined as

the temperature that exists just outside of the fan intake vents on the rear of the chassis. Note that

this temperature may be higher than ambient room temperature depending on the surrounding

equipment and/or blockages present. It is the user’s responsibility to ensure that this ambient

temperature does not exceed the rated ambient temperature as stated in Appendix A,

. If the temperature exceeds the stated spec the power switch LED will blink green,

Power Inhibit Switch LED Indicator

section of this chapter.

Setting Fan Speed

The fan-speed selector switch is on the rear panel of the NI PXIe-1082DC chassis. Refer to

Figure 1-2,

Rear View of the NI PXIe-1082DC Chassis

, to locate the fan-speed selector switch.

Select

High

for maximum cooling performance or

Auto

for improved acoustic performance.

When set to

Auto

, the fan speed is determined by chassis intake air temperature.

Rack Mounting

Rack mount applications require the optional rack mount kits available from National

Instruments. Refer to the instructions supplied with the rack mount kits to install your

NI PXIe-1082DC chassis in an instrument rack. Refer to Figure A-3,

.

1

Primary Air Exhaust Vent

2

Secondary Air Intake/Exhaust Vents

2

1

NI PXIe-1082DC