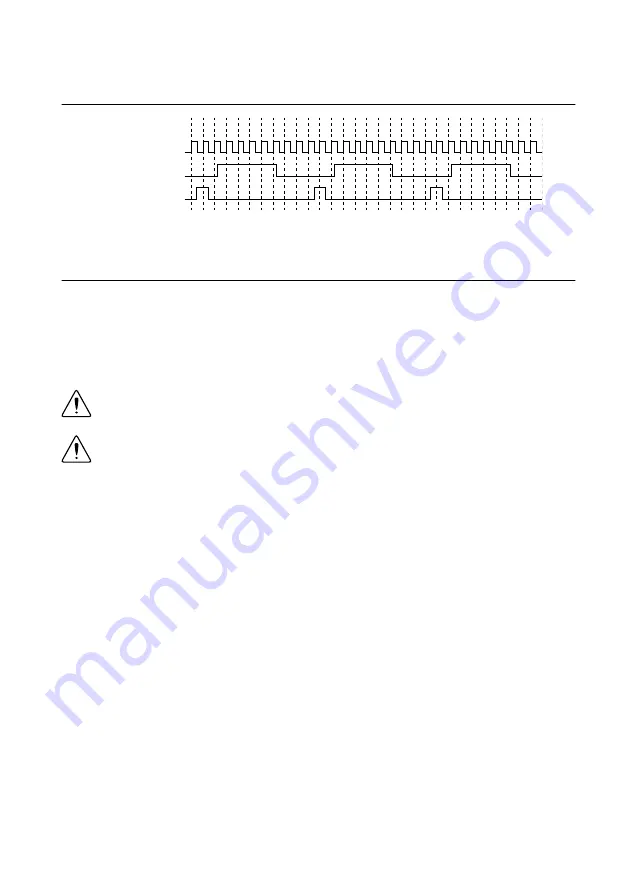

PXI_CLK10, PXIe_CLK100 and PXIe_SYNC100 have the default timing relationship

described in the following figure.

Figure 7. System Reference Clock Default Behavior

PXIe_CLK100

PXI_CLK10

PXIe_SYNC100

0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9

Installation and Configuration

The following section describes how to prepare and operate the PXIe-1083 chassis.

Before connecting the chassis to a power source, read this section and the

Read Me First:

Safety and Electromagnetic Compatibility

document included with your kit.

Safety Information

Caution

Before undertaking any troubleshooting, maintenance, or exploratory

procedure, carefully read the following caution notices.

Caution

Protection may be impaired if equipment is not used in the manner

specified.

This equipment contains voltage hazardous to human life and safety, and is capable of

inflicting personal injury.

•

Protective Earth—The facility installation must provide a means for connection to

protective earth.

•

Chassis Grounding—The chassis requires a connection from the premise wire safety

ground to the chassis ground. The earth safety ground must be connected during use of

this equipment to minimize shock hazards. Refer to the

Connecting Safety Ground

section

for instructions on connecting safety ground.

•

Live Circuits—Operating personnel and service personnel must not remove protective

covers when operating or servicing the chassis. Adjustments and service to internal

components must be undertaken by qualified service technicians. During service of this

product, the mains connector to the premise wiring must be disconnected. Dangerous

voltages may be present under certain conditions; use extreme caution.

•

Explosive Atmosphere—Do

not

operate the chassis in conditions where flammable gases

are present. Under such conditions, this equipment is unsafe and may ignite the gases or

gas fumes.

•

Part Replacement—Only service this equipment with parts that are exact replacements,

both electrically and mechanically. Contact NI for replacement part information.

10

|

ni.com

|

PXIe-1083 User Guide