58

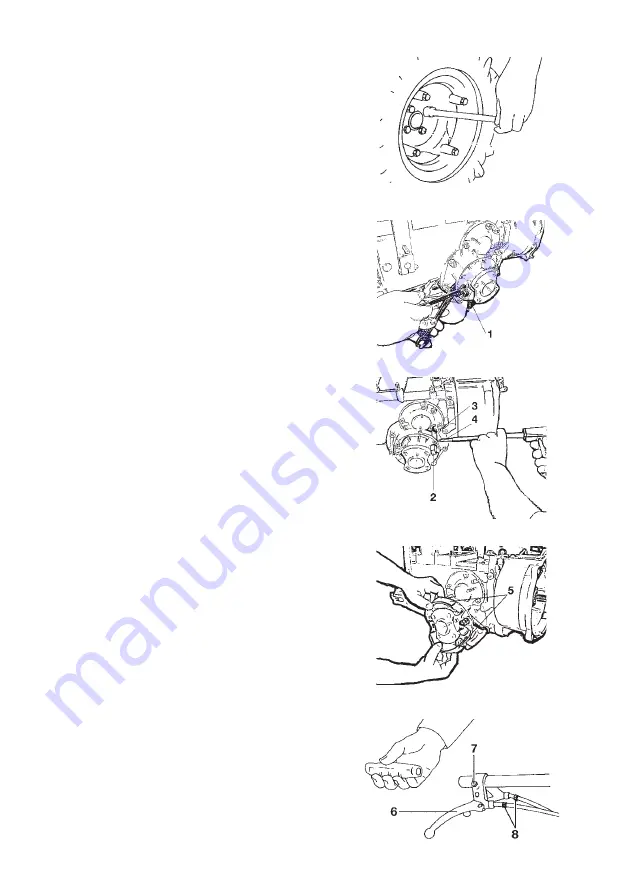

Fig. 15a

Fig. 15b

Fig. 15c

Fig. 15d

Fig. 15e

BRAKE ASSEMBLY INSTRUCTIONS

(Fig. 15)

1)

Place the engine on a stable support.

2)

Unscrew the wheel fixing screws (Fig. 15a

).

3)

Lift the engine driven cultivator from the

power take-off side and completely remove

the wheels.

4)

From the brake kit, take the brake suppor

-

ting threaded stud (1) and the relevant nut

and mount it into its seat (power take-off side).

Fully tighten with two wrenches (fig. 15b).

5)

Insert the block opening stud (2) into its

seat, engage the pin control lever (3) and,

by using a drift and a hammer, fix it with pin

(4) into the stud (fig. 15c).

CAUTION: every stud has a right or left

side as mentioned on it.

We remind you that the machine right and

left sides are identified by the operator

working from the machine handlebar with

the steering column in milling position.

6)

Insert the brake shoes (5) on the appro

-

priate half-support pins.

When assembling, make sure that the brake

shoe springs are in correspondence with the

axle shaft undercuts(fig. 15 d).

7)

Assemble the brake drum (11) and wheel

by means of fixing screws (1).

8)

After having removed the handlebar grip,

insert lever (6) and lock it in its position by

using screw (7).

9)

Screw adjuster (8) on lever (6).

10)

Insert the wire on the brake lever 6) and

on the brake shoe lever control (3).

11)

Adjust the lever clearance to 8mm by opera

-

ting on the wire clamp and on adjuster (8).

12)

Reassemble the grip (Fig. 15e).