1

Instruction Manual

US

HE.13575_A © 06/2010

PC-280

1

Instruction Manual

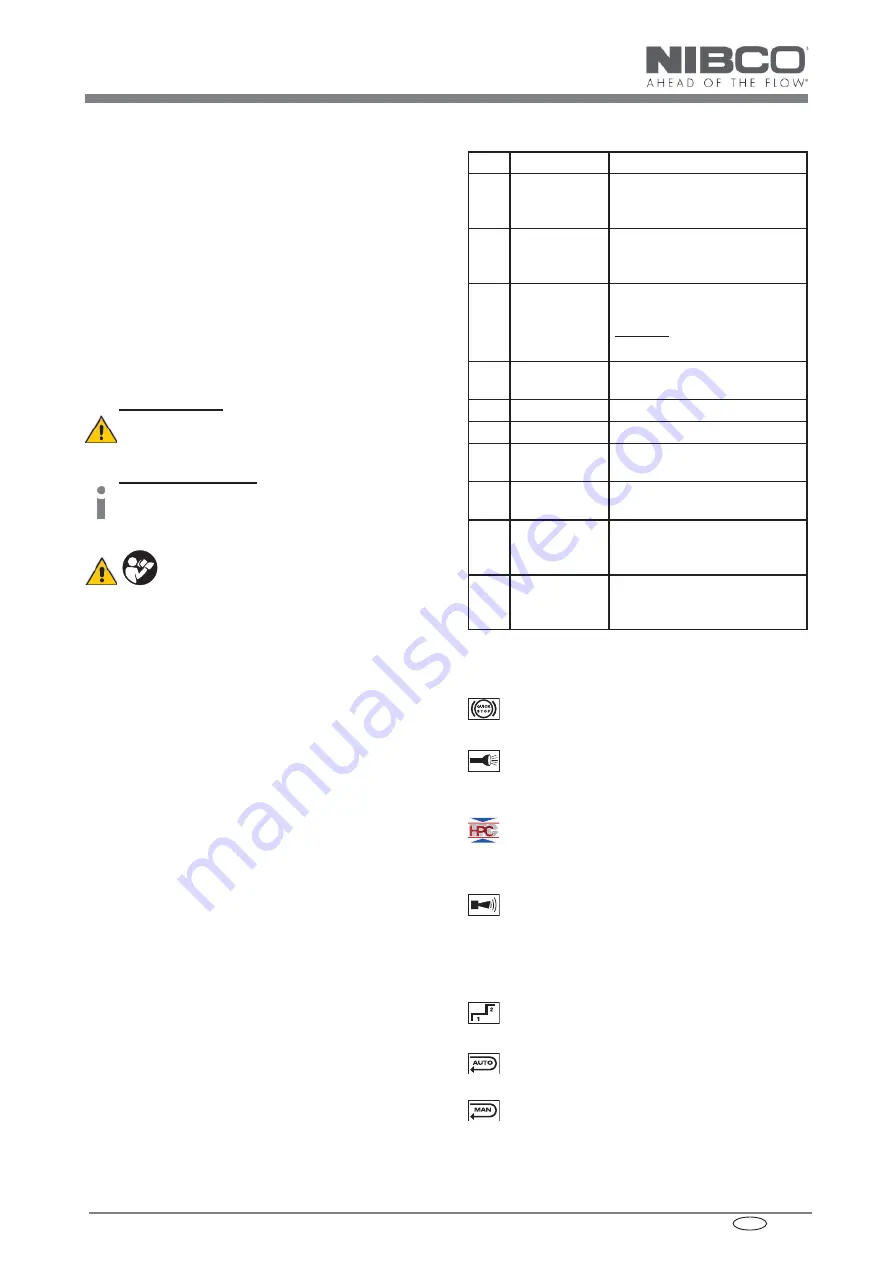

Tab. 2 (see page I, pic. 1)

Pos.

Description

Function

1

LED (red)

Indicator for battery charge

control, tool functions and

faults

2

Retract slide

Slide to retract the drive rollers

in case of an error or emer-

gency

3

Battery

cartridge

Rechargeable 3 Ah Li-Ion

battery (PC-7L)

Optional:

adapter PC-9L

4

Trigger

Operating switch

to start the motor

5

LED (white)

To illuminate the working area

6

Pin

Bolt to lock the pressing jaws

7

Pressing jaws

To press the fi tting on the

pipes

8

Pressing head

Reception for the pressing

jaws

9

Protection

sleeve

Adaptable protection sleeve for

the intended application of dif-

ferent pressing jaws / - chains

10

Housing

Ergonomically formed plastic

housing in a 2-Component

design for perfect handling

2.2 Brief description of the important

features of the unit

Safety features:

The unit is equipped with a special brake which in-

stantly stops the forward motion of the piston/dies

when the trigger is released.

A white LED illuminates the working space after ac-

tivating the trigger. It automatically switches off 10

sec. after releasing the trigger. This feature can be

deactivated (see page V)

Hydraulic Pressure Check, HPC for short, monitors

the oil pressure in the tool’s oil circuit, hence ensur-

ing a continuous, consistent press quality.

During each pressing cycle, the achieved pressing

pressure is determined by a pressure sensor and

compared to the required minimum value. An au-

dible warning signal sounds if the achieved pres-

sure differs from the specified working pressure.

The user will know immediately that the fi tting must

be checked and repressed or replaced as required.

Functional features:

The unit is equipped with a double piston pump

which is characterized by a rapid approach of the

rollers towards the jaws and power speeds.

The hydraulic unit incorporates an automatic retrac-

tion which returns the piston into its starting position

when the maximum operating pressure is reached.

A manual retraction allows the user to return the pis-

ton into the starting position in case of an incorrect

compression.

Index

1.

Introduction

2.

Description of the pressing tool

2.1 Components of the unit

2.2 Brief description of the important features

of the unit

3.

Remarks with respect to the intended use

3.1 Operation of the unit

3.2 Explanation of the application range

3.3 Installation

instructions

3.4 Service and maintenance instructions

4. Troubleshooting

5.

Technical data

Symbols

Safety warnings

Please do not disregard these instructions in or-

der to avoid human injuries and environmental

damage.

Operational warnings

Please do not disregard them to avoid dama-

ging the tool.

1. Introduction

Before starting to use the tool please read

the instruction manual carefully.

Use this tool exclusively for its determined use respecting

all international and domestic health and safety regulati-

ons.

Use this tool exclusively for its determined use.

This instruction manual has to be carried along during the

entire life span of the tool.

The operator has

• to guarantee the availability of the instruction manual

for

the user and

• to make sure, that the user has read and understood

the instruction manual.

2. Description of the pressing tool

2.1 Components of the tool

The electric-hydraulic tool is hand guided and consists of

the following components: