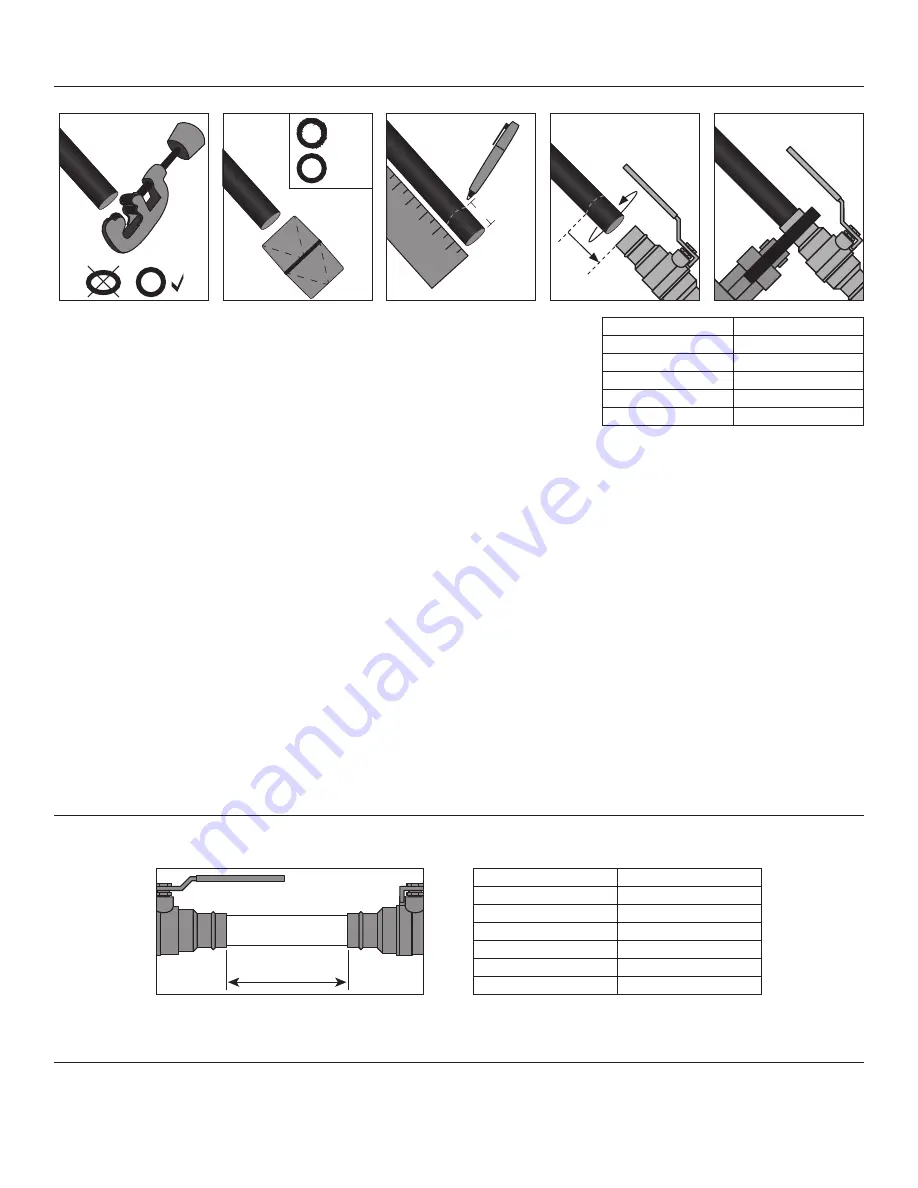

Step 1 – Match Tubing and Valve Size, Cut Tubing

Match the copper piping with the appropriate Pro-Connect™ Press Air Separator. Verify that

both the pipe and Pro-Connect™ Press Air Separator product are clean, undamaged and

appropriate for the intended service. Cut the tubing to the proper length necessary for the

installation.

IMPORTANT: The pipe must be long enough to fit inside the Pro-Connect

™

Press Air

Separator, not just to reach its face.

The approximate depth that the pipe will be inserted is shown in the table above.

When cutting the pipe, care must be exercised to ensure that it remains round and does not get flattened into an oval. Failure to do so

may affect the performance of the joint.

Step 2 – Deburr Pipe

Both inside and outside of the tubing must be cleaned of burrs prior to installation. Failure to properly deburr the interior and exterior

of the tubing may result in damage to the product’s o-ring and cause the product to leak.

Step 3 – Measure Pipe Insertion Depth

Prior to installing the pipe into the Pro-Connect™ Press Air Separator, measure the approximate insertion depth from the end of the

line and mark it with felt tipped pen.

Step 4 – Insert Pipe

Insert the pipe into the Pro-Connect™ Press Air Separator and slowly turn the tube or product until pipe reaches fitting stop. Water

may be used as a lubricant if desired, HOWEVER NO OTHER LUBRICANTS MAY BE USED. Verify the tubing has been fully inserted into

the valve by measuring the distance between the end of the product and the line drawn on the tubing in Step 3. The line should be no

further than 1/16" (1.5 mm) from the end of the press connection.

Step 5 – Pro-Connect

™

Press Fitting

Verify that the pipe is fully inserted to the mark. Keeping the jaw of the tool at a right angle to the product, center the jaw on the ring in

the connection. Follow the instructions provided by the tool manufacturer to press the connection.

STEP 3: MEASURE

STEP 2: DEBURR

STEP 1: CUT

STEP 4: INSERT PIPE

X

BEFORE

AFTER

STEP 5: PRESS CONNECTION

Installing Pro-Connect

™

Press Connections

To ensure a proper seal, a minimum distance is required between fittings. Failure to provide the required distance may distort the pipe,

resulting in an ineffective seal.

The piping system can be checked for leaks once all connections have been completed. In the event a leaky connection is found,

re-press the fitting following the instructions above. System testing should be completed in accordance with requirements or codes of

any federal/state/local governing body having jurisdiction over the installation. Pro-Connect™ Pressure testing should not exceed the

Pro-Connect™ Press Air Separator’s maximum pressure rating of 150 PSI.

Minimum Distance Between Pro-Connect

™

Press Connections

System Testing

TUBING DIAMETER

MINIMUM DISTANCE

1/2"

0"

3/4"

0"

1"

0"

1 1/4"

7/16"

1 1/2"

5/8"

2"

3/4"

MINIMUM

DISTANCE

PRODUCT SIZE

INSERTION DEPTH

3/4"

1 9/16"

1"

1 9/16"

1 1/4"

1 11/16"

1 1/2"

1 7/8"

2"

2 1/8"