19

www.climacoolcorp.com

Water Piping

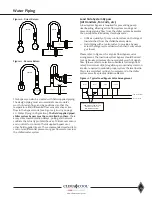

Figure 10 - Direct Return

No. 25 Grooved Branch

6 x 6 x 2

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

No. 25 Grooved Branch

6 x 6 x 2

Module

Header

6"

Gro

ove

d

Couplin

g

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

6"

Gro

ove

d

Couplin

g

SIDE VIEW

2" Belimo

Ball Valve &

Actuator

Hose Kit

2"

Grooved

Coupling

Figure 11 - Reverse Return

No.10

2" 90°

No.50

Reducer

6 x 2

Module

Header

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

SIDE VIEW

6"

Gro

ove

d

Couplin

g

6"

Gro

ove

d

Couplin

g

2"

Gr

oove

d

Cou

plin

g

Hose Kit

2"

Grooved

Coupling

2" Belimo

Ball Valve &

Actuator

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

No.10

2" 90°

Elbow

No.50 Reducer

6 x 2

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

This bypass can also be created with field supplied piping.

The design piping must accommodate one module’s

worth of design flow, and be positioned so that the

temperature and differential flow sensors sense active

flow in the bypass mode (see Figures 13 and 14 on page

20 - Water Piping Configuration).

The field supplied piped

chiller system bypass must be controlled by others.

There

are system communication delays, polling and network

conflicts that strictly prohibit the use of ClimaCool sensors

and controls for control of field supplied bypasses or

other field supplied items. The recommended method is to

control via differential pressure or gpm flow meters across

the chilled water system .

Load Side System Bypass

(Air Handlers, Fan Coils, etc.)

A load system bypass is required for preventing pump

deadheading, allowing active flow system sensing and

preventing starving flow from the chiller system. Examples

of an acceptable load side system bypass are:

•

Utilize a quantity of 3-way control valves on the largest

loads farthest from the chiller/heater system .

•

Field piping with a control valve to provide a bypass

across the larger system loads when their 2-way valves

go closed .

Please refer to Figure 11 for a typical load bypass valve

arrangement . The load side system bypass should be sized

for an absolute minimum of one module’s worth of design

flow. (Please refer to selection submittals for design flow

rates) . A minimum of (6) six gallons per nominal system ton

are also required to maintain proper system thermal inertia .

This is to avoid short cycling of compressors in the chiller

system as well as prevent nuisance alarms .

Figure 12 - Typical Load Bypass Valve Arrangement

LOAD 1

FROM CHILLER BANK

TYPICAL LOAD BYPASS VALVE ARRANGEMENT

TO CHILLER BANK

LOAD 2

LOAD 3

LOAD X

TYPICAL CHILLED AND HOT WATER

LOAD SIDE BYPASS VALVES

SIZE EQUIVALENT TO

MINIMUM BANK FLOW

TYPICAL CHILLED AND HOT WATER

LOAD SIDE BYPASS VALVES

SIZE EQUIVALENT TO

MINIMUM BANK FLOW

Summary of Contents for CLIMACOOL UCR 30

Page 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Page 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Page 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

Page 78: ...76 www climacoolcorp com Wiring Diagram...

Page 79: ...77 www climacoolcorp com Wiring Diagram...

Page 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Page 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...