37

www.climacoolcorp.com

Head Pressure Control Valve Operation (LAC-10)

WARNING:

Serious injury could result from an explosion

caused by the rapid expansion of trapped liquid refrigerant

subjected to high temperature .

ALWAYS OPEN OR VENT

THE SYSTEM BEFORE APPLYING HEAT TO REMOVE SYSTEM

COMPONENTS.

Break the element charging cap tube on

valve dome by hand or with a clean cut tool . DO NOT use

side cutters, which may seal the opening .

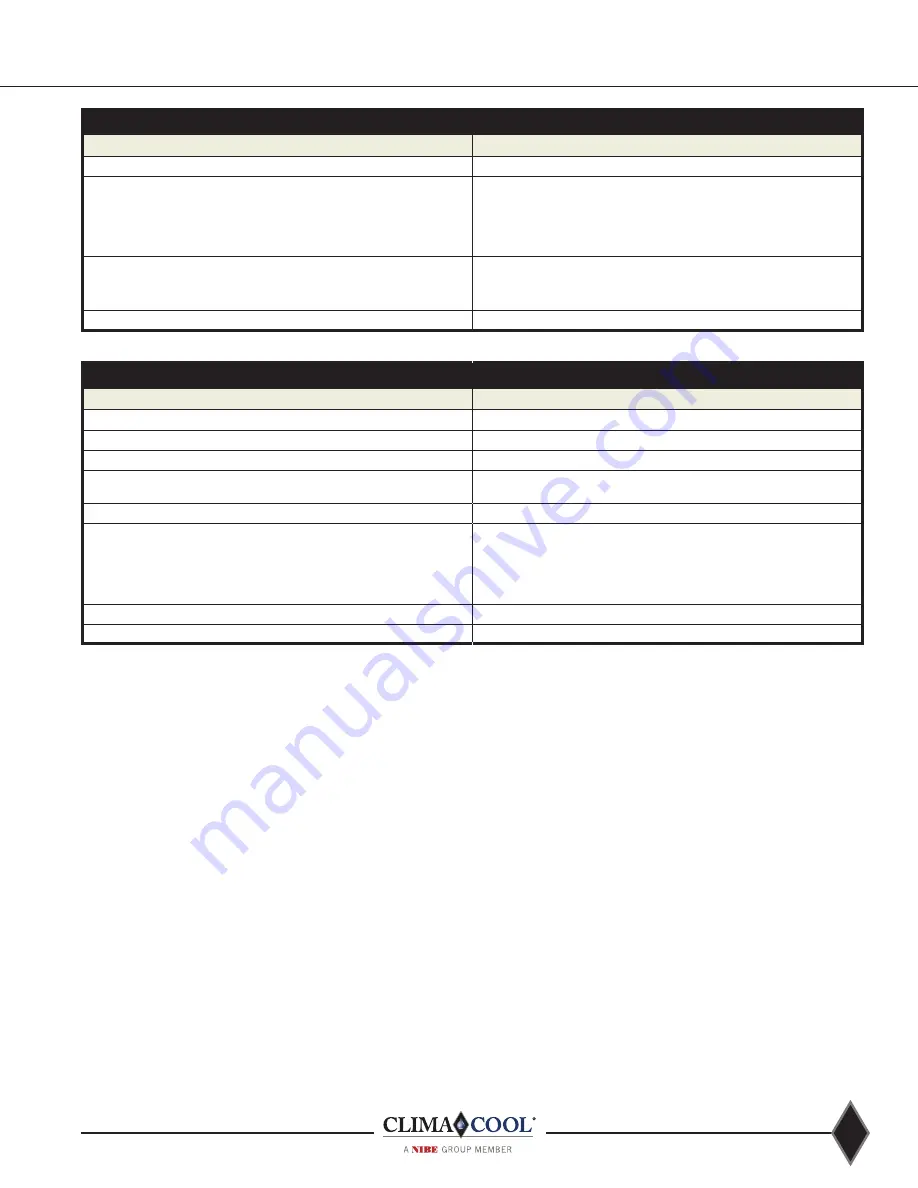

Malfunction – Low Head Pressure Chart

Possible Cause

Remedy

Insufficient refrigerant charge to adequately flood condenser

Add refrigerant

LAC fails to close due to:

a. Foreign material in valve

b. Loss of air charge in element

See Below:

a. Cause LAC to open by raising condensing/receiver pressure above

valve setting by cycling condenser fan. If foreign material does not pass

through valve, replace LAC

b. Replace LAC

LAC receiver port fails to open due to:

a. Less that 20 psi pressure drop across inlet to receiver port

b. Internal parts damaged by overheating when installed

See Below:

a. Check LAC causes/remedies

b. Replace LAC

Discharge line to LAC restricted

Remove restriction in fitting(s) or line

Malfunction – High Head Pressure Chart

Possible Cause

Remedy

Dirty condenser coil

Clean coil

Air on condenser blocked off

Clean area around condenser

Too much refrigerant charge

Remove charge until proper head pressure is maintained

Undersized receiver

Check receiver capacity against refrigerant required to maintain desired

head pressure

Non-condensibles (air) in system

Recover, evacuate and recharge

Bypassing hot gas when not required due to:

a. Internal parts of the Inlet to receiver port of the LAC are damaged by

overheating when installed

b. If pressure drop across the condenser, associated piping and LAC

exceeds 14 psi under full load conditions

See Below:

a. Replace LAC

b. Contact Factory

Liquid port or liquid line plugged

Remove blockage in port or liquid line

Condenser fans not running

Repair or replace fan motor

Installation Precautions

1 .

Do not overcharge — see charging procedures on

page 34 .

2 .

Be sure that the piping does not allow liquid refrigerant

to be trapped in sections where hydrostatic pressure

can develop .

3 .

Be sure that the receiver is large enough to hold the

entire charge during “warm” operation .

4 .

Do not overheat — see brazing procedures on page 33 .

Summary of Contents for CLIMACOOL UCR 30

Page 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Page 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Page 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

Page 78: ...76 www climacoolcorp com Wiring Diagram...

Page 79: ...77 www climacoolcorp com Wiring Diagram...

Page 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Page 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...