69

www.climacoolcorp.com

Stainless Steel Strainer Option

Operation Instructions

Flush valve line must be piped to atmospheric pressure such

as an open floor drain. The flush line should not undergo

any changes in elevation and should be sloped downward in

the direction of drainage .

Do not pipe the flush or drain line

into a pressurized line.

Note:

The Automatic Timer Flush Package needs to be

programmed when it is received by the end-user . The

programming is simple and takes only a few moments .

However, because every application has different

parameters that affect the required frequency between

flushes and the duration of the flush, the end-user must

choose the controller’s settings (refer to the specific

strainer manual) .

To Program the ATF Controller

1 .

Plug the transformer into a 120-VAC outlet .

2 .

Insert the 12-VDC plug coming from the transformer into

the jack on the underside of the ATF box .

3 .

Test for power by pressing the manual flush side of the

control switch (lower switch light should come on then

the valve will start to open) .

4 .

Adjust the “ON TIME” (Valve Open) by turning the

inner timer ring with the GREEN POINTER clockwise to

increase duration . The ON TIME RANGE is factory set at

eight seconds (see Figure 29) .

5 .

Adjust the “OFF TIME” (Valve Close) by turning the

outer ring with the RED POINTER clockwise to increase

duration . The OFF TIME RANGE is factory set at twenty-

four (24) hours (see Figure 29) .

6 .

Set the control switch to auto flush. The red off light on

the timer will come on and the upper light on the switch

will come on and stay on. During the flush cycle the on

light on the timer and the lower switch light will come on .

Control Switch

Control switch flushing is initiated by pressing and holding

down the manual control switch located on the front of the

controller (see Figure 30). The manual flush control switch

can also be used to conveniently drain the water out of the

strainer before removing the conical screen element from

the strainer housing . A yellow indicator arrow on top of

the ATF valve will rotate in sync with the ball valve to show

the valve position (open or closed). When the manual flush

control switch is released, the valve will automatically close .

SAFETY FIRST! - Keep fingers away from valve opening

to avoid getting caught in the moving parts. The electric

motor supplied a sufficient amount of power to cause

personal injury. Take precaution when handling.

Water Resistance

The valve and controller are water-resistant, but not

water-proof . Do not install below ground level where the

component can be submerged in water . Only remove

the cover plate from the valve controller when setting or

changing the flush settings. Keep the cover tightly sealed on

the unit during normal operation .

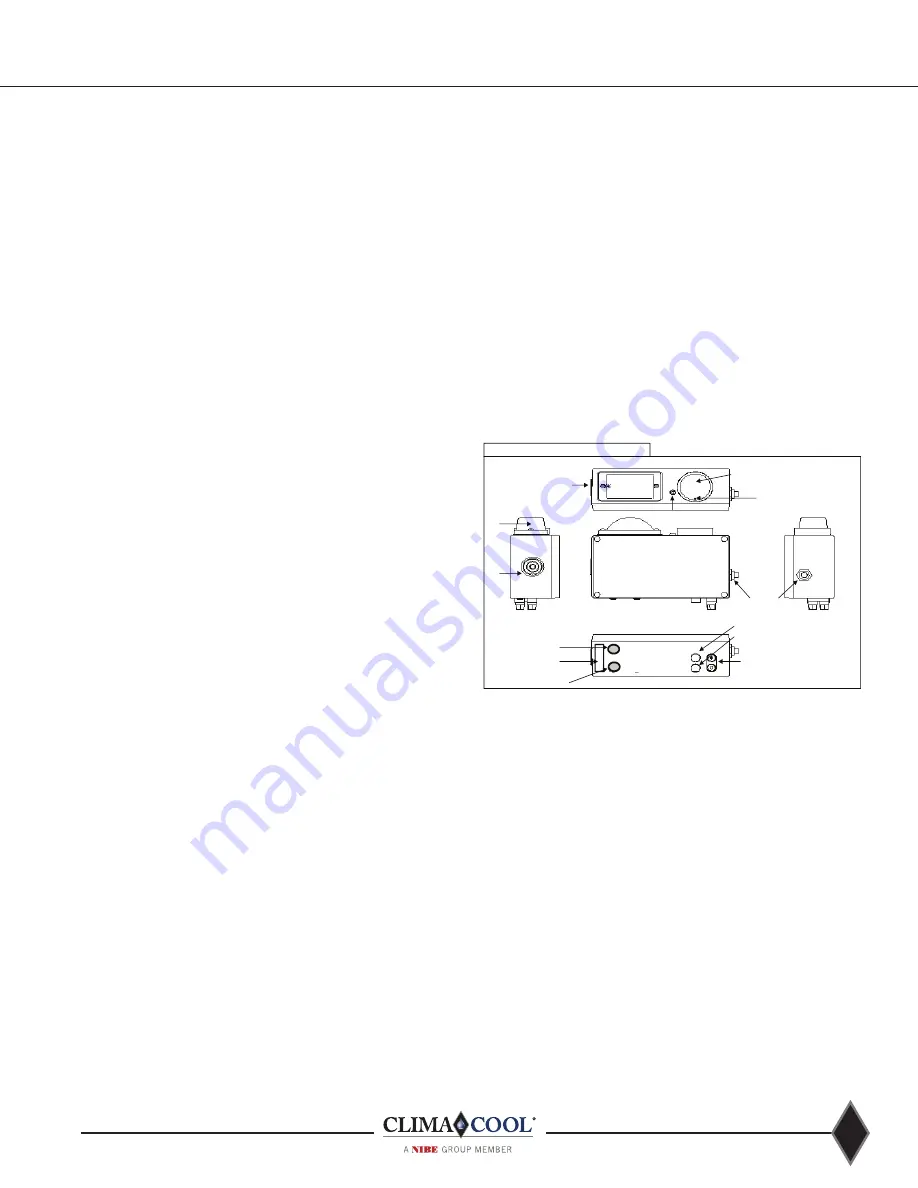

Pressure Differential Alarm Package Option

The pressure differential alarm (PDA) option continually

monitors and displays the strainer’s inlet and outlet

differential pressure. When the strainer element (conical

strainer basket) becomes significantly clogged, the pressure

differential switch-gauge will trigger an audible siren and a

visual flashing alarm light. These alarms are intended to alert

maintenance personnel that the strainer element must be

removed and cleaned (see Strainer Element Cleaning on page

67) .

Figure 32

PSID High

PSID Low

Pressure Differential Alarm (PDA) option

Alarm Reset Button

FRONT

VIEW

LEFT SIDE

VIEW

Power To ATF

110 Volt/12 Volt DC

Wall Transformer

Visual

Alarm

Audible

Alarm

Pressure Differential

Switch-Gauge

LED Power Indicator

Differential

Set-Point Contact

Cover-Plate Screw (4) in Corners of

Box (DO NOT REMOVE).

Visual

Alarm

RIGHT SIDE

VIEW

TOP

VIEW

BOTTOM

VIEW

AUX Contacts

(On or Off with Alarm)

Red & Black

Cable Retainer

Operation Instructions

Remove the power supply and insert the connector end into

the socket on the bottom of the PDA housing (See Figure

32 above) and plug the transformer into the power source .

Standard systems are supplied with a 120V power supply to

the primary of the transformer, with an output secondary of

12 VDC. The pressure differential switch-gauge is factory set

to 7-8 psi. The CS strainer operates at a pressure differential

slightly less than 1 psi during maximum flow when the

strainer screen is clean. By the time the differential pressure

reaches 7-8 psi, the strainer element will be significantly

clogged and require immediate removal and cleaning . To

adjust the pressure differential switch-gauge setting, insert

a 1/16” allen wrench and rotate the differential set point

contact to the desired location (see Figure 27) .

Note:

It is not

recommended to set the differential switch-gauge higher

than 10 psi . Disabling the alarm or increasing the alarm set

point could result in damage to the strainer element and

allow debris to pass into the system .

Summary of Contents for CLIMACOOL UCR 30

Page 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Page 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Page 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

Page 78: ...76 www climacoolcorp com Wiring Diagram...

Page 79: ...77 www climacoolcorp com Wiring Diagram...

Page 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Page 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...