42

G e o t h e r m a l H e a t i n g a n d Co o l i n g

Tranquility

®

22 Digital (TZ

)

Series - 60Hz

R e v. : N o v e m b e r 1 8 , 2 0 2 2

UNIT START-UP PROCEDURE

1.

Turn the thermostat fan position to “ON.” Blower

should start.

2. Turn Blower off.

3. Ensure all valves are adjusted to their full open position.

Ensure line power to the heat pump is on.

4. Room temperature should be within the minimum-

maximum ranges of listed in the unit IOM. During start-

up checks, loop water temperature entering the heat

pump should be between 30°F [-1°C] and 95°F [35°C].

5.

It is recommended that water-to-air units be first

started in the cooling mode, when possible. This will

allow liquid refrigerant to flow through the filter-drier

before entering the TXV, allowing the filter-drier to

catch any debris that might be in the system before it

reaches the TXV.

6. Two factors determine the operating limits of geothermal

heat pumps, (a) return air temperature, and (b) entering

water temperature. When either of the factors is at a

minimum or maximum level, the other factor must be at

normal levels to insure proper unit operation.

a. Place the unit in Manual Operation. When in

manual mode activate Y1, Y2, and O to initiate the

cooling mode. Also manually increase CFM until

desired cooling CFM is achieved. Next adjust pump

speed % until desired loop temperature difference

(leaving water temperature minus entering water

temperature) is achieved. (For modulating valve

adjust valve %).

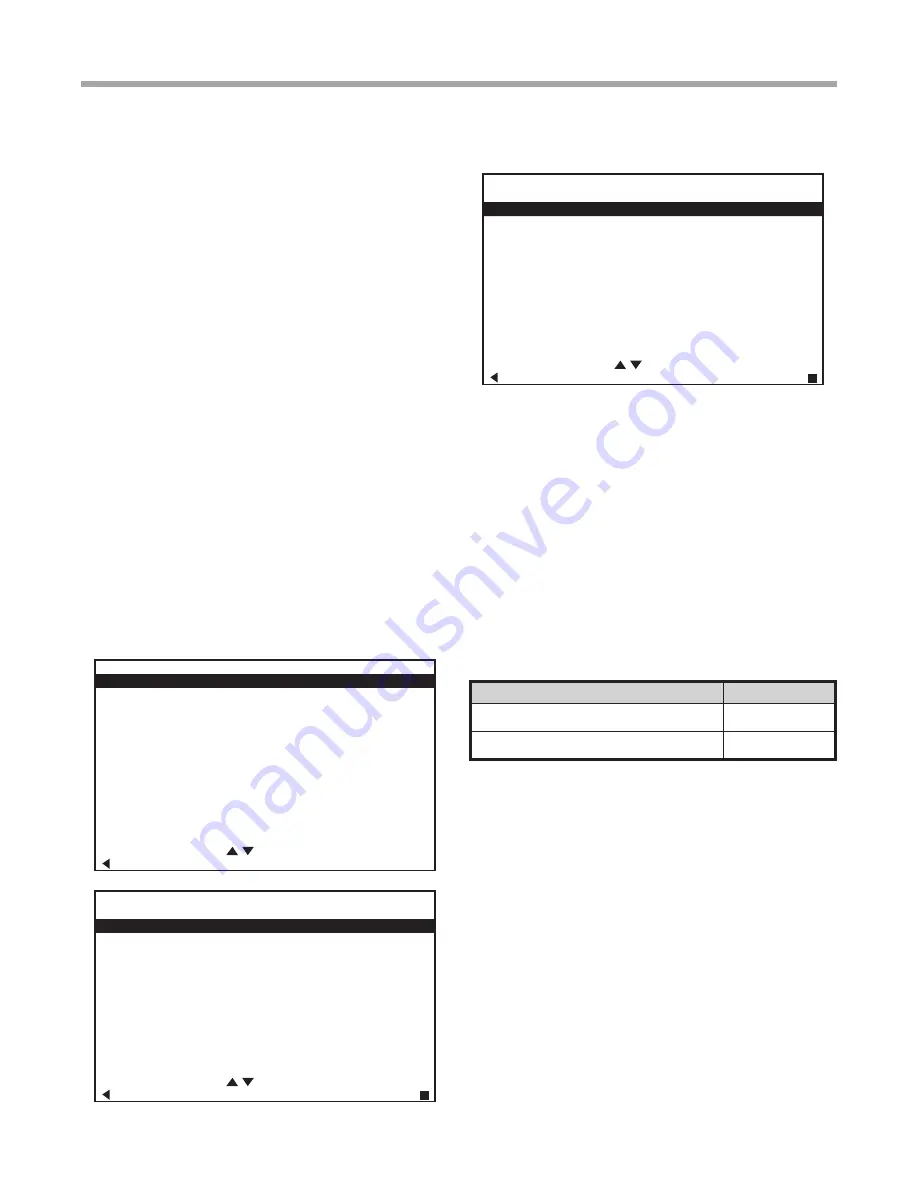

INSTALLER SETTINGS

THERMOSTAT CONFIG

SYSTEM CONFIG

ACCESSORY CONFIG

INPUT DEALER INFO

HUMIDITY CONFIG

TEMPERATURE CONTROL

DEMAND REDUCTION CNFG

SERVICE MODE

SETPOINT LIMITS

RESTORE DEFAULTS

DXM2.5 3.3

AWC99U01 C 1.0

SELECT OPTION

PREVIOUS

SERVICE MODE

MANUAL OPERATION

CONTROL DIAGNOSTICS

DIPSWITCH CONFIG

FAULT HISTORY

CLEAR FAULT HISTORY

SELECT OPTION

PREVIOUS SELECT

MANUAL OPERATING MODE

Y1

COMM OUTPUT

OFF

Y2

COMM OUTPUT

OFF

W

COMM OUTPUT

OFF

O

COMM OUTPUT

OFF

G

COMM OUTPUT

OFF

H

COMM OUTPUT

OFF

DH

COMM OUTPUT

OFF

ECM AIRFLOW

0

PUMP SPEED

0%

TEST MODE

OFF

SELECT OPTION

PREVIOUS SELECT

b. Check for cool air delivery at the unit grille within a

few minutes after the unit has begun to operate.

NOTE: Units have a five minute time delay in the control

circuit that can be bypassed on the DXM2.5 control board

by placing the unit in the “Test” mode as shown in the unit

IOM. Check for normal air temperature drop of 15°F to

25°F (cooling mode).

c. Verify that the compressor is on and that the water

temperature rise (cooling mode) is within normal

range.

d. Check the elevation and cleanliness of the

condensate lines. Dripping may be a sign of a

blocked line. Check that the condensate trap is filled

to provide a water seal.

Water Flow, gpm (l/m)

Rise, Cooling °F

For Closed Loop:

Ground Source or Closed

Loop Systems at 3 gpm per ton (3.9 l/m per kw)

9 - 12

For Open Loop:

Ground Water Systems at

1.5 gpm per ton (2.0 l/m per kw)

20 - 26

e. Turn thermostat to “OFF” position. A hissing noise

indicates proper functioning of the reversing valve.

7.

Allow five (5) minutes between tests for pressure to

equalize before beginning heating test.

a. Go into Manual Mode activate Y1, and Y2 for

Heating. Also manually increase CFM until desired

heating CFM is achieved. Next adjust pump

speed % until desired loop temperature difference

(entering water temperature minus leaving water

temperature) is achieved. (For modulating valve

adjust valve %).

b. Check for warm air delivery at the unit grille within a

few minutes after the unit has begun to operate.

NOTE: Units have a five minute time delay in the control

circuit that can be bypassed on the DXM2.5 control board

by placing the unit in the “Test” mode as shown in the unit

IOM. Check for normal air temperature rise of 20°F to 30°F

(heating mode).

Unit Start-Up Procedure