47

c l i m a t e m a s t e r.c o m

Tranquility

®

22 Digital (TZ

)

Series - 60Hz

R e v. : N o v e m b e r 1 8 , 2 0 2 2

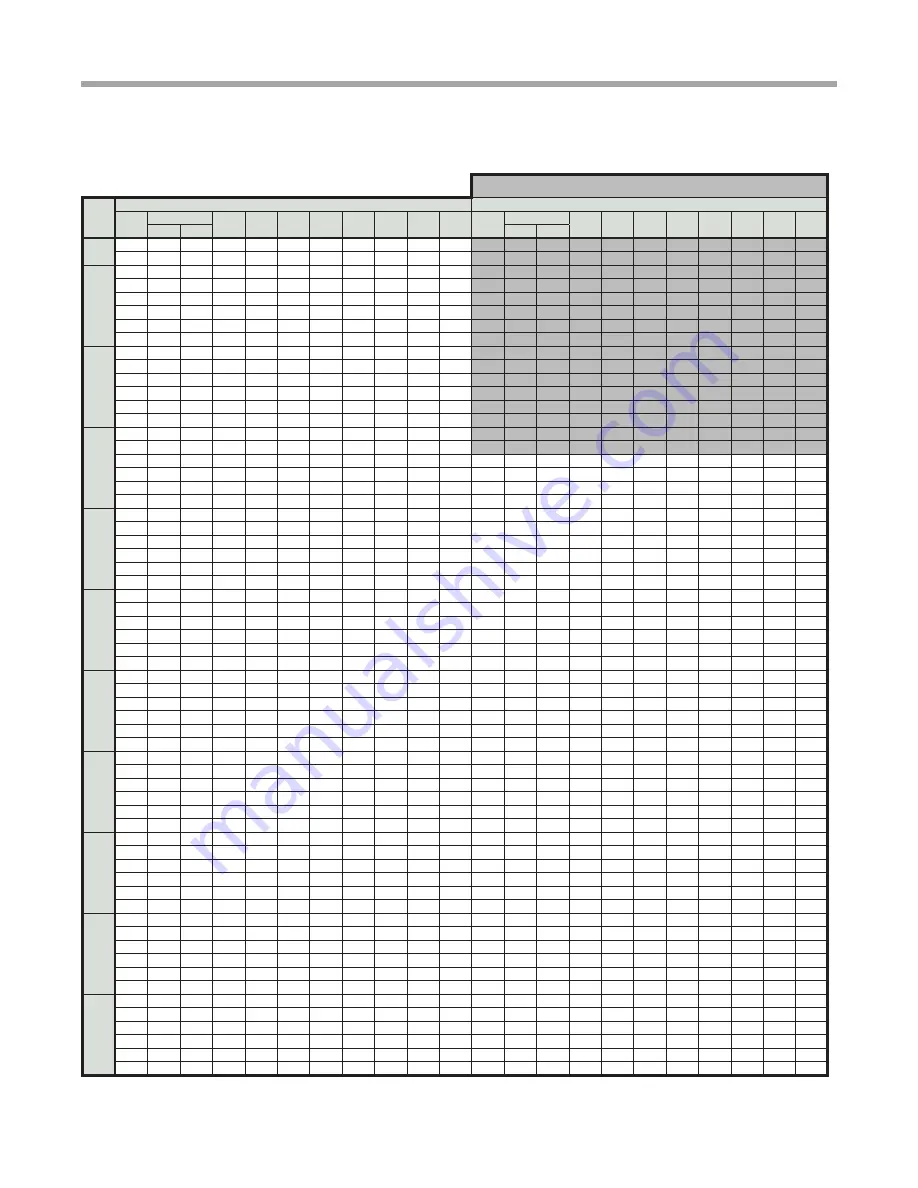

Performance Data – Model 024 Part Load with vFlow

®

Performance capacities shown in thousands of Btuh

Antifreeze use recommended in this range.

Also Clip JW3 on DXM2.5 board.

EWT

°F

Cooling - EAT 80/67°F

Heating - EAT 70°F

GPM

WPD

CFM

TC

SC

kW EER

HR LWT HWC GPM

WPD

CFM HC

kW COP HE

LAT LWT HWC

PSI

FT

PSI

FT

20

1.2

0.3

0.7

480

22.0 13.9 0.68 32.4 24.3 60.0

0.9

5.0

3.7

8.4

480

10.6 1.16

2.7

6.7

90.5 17.3

2.0

1.2

0.3

0.7

600

22.4 15.2 0.71 31.6 24.9 60.0

0.9

5.0

3.7

8.4

600

10.9 1.12

2.8

7.0

86.7 17.2

1.9

30

1.7

0.3

0.6

480

22.0 13.9 0.68 32.4 24.3 60.0

0.9

2.5

0.8

1.9

480

12.2 1.18

3.0

8.1

93.5 23.5

2.0

1.7

0.3

0.6

600

22.4 15.2 0.71 31.6 24.9 60.0

0.9

2.5

0.8

1.9

600

12.4 1.14

3.2

8.5

89.2 23.2

1.9

1.7

0.3

0.6

480

22.0 13.9 0.68 32.4 24.3 60.0

0.9

3.8

1.8

4.2

480

12.7 1.19

3.1

8.7

94.5 25.4

2.0

1.7

0.3

0.6

600

22.4 15.2 0.71 31.6 24.9 60.0

0.9

3.8

1.8

4.2

600

13.0 1.15

3.3

9.1

90.0 25.2

1.9

1.7

0.3

0.6

480

22.0 13.9 0.68 32.4 24.3 60.0

0.9

5.0

2.9

6.7

480

13.0 1.19

3.2

9.0

95.1 26.4

2.1

1.7

0.3

0.6

600

22.4 15.2 0.71 31.6 24.9 60.0

0.9

5.0

2.9

6.7

600

13.3 1.15

3.4

9.4

90.5 26.3

2.0

40

2.5

0.5

1.2

480

22.0 13.9 0.68 32.4 24.3 60.0

0.9

2.5

0.5

1.2

480

14.5 1.21

3.5

10.3 97.9 31.7

2.1

2.5

0.5

1.2

600

22.4 15.2 0.71 31.6 24.9 60.0

0.9

2.5

0.5

1.2

600

14.8 1.17

3.7

10.8 92.8 31.4

2.0

2.5

0.5

1.2

480

22.0 13.9 0.68 32.4 24.3 60.0

0.9

3.8

1.4

3.2

480

15.2 1.22

3.6

11.0

99.3

34.1

2.2

2.5

0.5

1.2

600

22.4 15.2 0.71 31.6 24.9 60.0

0.9

3.8

1.4

3.2

600

15.5 1.18

3.8

11.5

93.9 33.9

2.1

2.5

0.5

1.2

480

22.0 13.9 0.68 32.4 24.3 60.0

0.9

5.0

2.4

5.4

480

15.6 1.22

3.7

11.4 100.0 35.4

2.2

2.5

0.5

1.2

600

22.4 15.2 0.71 31.6 24.9 60.0

0.9

5.0

2.4

5.4

600

15.9 1.18

3.9

11.9 94.5 35.2

2.1

50

2.5

0.3

0.8

480

21.3 13.6 0.76 27.8 23.9 69.1

1.1

2.5

0.3

0.8

480

16.8 1.23

4.0

12.6 102.4

39.9

2.3

2.5

0.3

0.8

600

21.7 14.8 0.80 27.1 24.4 69.6

1.1

2.5

0.3

0.8

600

17.2 1.19

4.2

13.1 96.5 39.5

2.2

3.8

1.1

2.5

480

21.8 13.8 0.71 30.8 24.2 62.9

0.9

3.8

1.1

2.6

480

17.7 1.24

4.2

13.4 104.1 42.8

2.3

3.8

1.1

2.5

600

22.2 15.1 0.74 30.0 24.7 63.2

0.9

3.8

1.1

2.6

600

18.0 1.20

4.4

13.9 97.8 42.6

2.2

5.0

2.0

4.5

480

22.0 13.9 0.68 32.4 24.3 60.0

0.9

5.0

2.0

4.5

480

18.1 1.25

4.2

13.9 105.0 44.4

2.4

5.0

2.0

4.5

600

22.4 15.2 0.71 31.6 24.9 60.0

0.9

5.0

2.0

4.5

600

18.5 1.21

4.5

14.4 98.6 44.2

2.3

60

2.5

0.3

0.6

480

20.4 13.2 0.88 23.3 23.4 78.7

1.6

2.5

0.3

0.6

480

19.1 1.26

4.4

14.8 106.8 48.2

2.4

2.5

0.3

0.6

600

20.9 14.4 0.92 22.7 24.0 79.2

1.6

2.5

0.3

0.6

600

19.5 1.22

4.7

15.3 100.1 47.7

2.3

3.8

0.9

2.2

480

21.0 13.4 0.80 26.2 23.7 72.7

1.3

3.8

0.9

2.2

480

20.0 1.27

4.6

15.7 108.6 51.6

2.5

3.8

0.9

2.2

600

21.4 14.7 0.84 25.5 24.3 73.0

1.3

3.8

0.9

2.2

600

20.4 1.23

4.9

16.2 101.5 51.3

2.4

5.0

1.7

3.9

480

21.3 13.6 0.76 27.8 23.9 69.5

1.1

5.0

1.7

3.9

480

20.5 1.28

4.7

16.1 109.6 53.5

2.6

5.0

1.7

3.9

600

21.7 14.8 0.80 27.1 24.4 69.8

1.1

5.0

1.7

3.9

600

20.9 1.24

5.0

16.7 102.3 53.3

2.5

70

2.5

0.2

0.6

480

19.5 12.7 1.01 19.2 22.9 88.3

2.1

2.5

0.2

0.6

480

21.2 1.29

4.8

16.8 110.9 56.6

2.6

2.5

0.2

0.6

600

19.9 13.9 1.06 18.7 23.5 88.8

2.2

2.5

0.2

0.6

600

21.6 1.25

5.1

17.4 103.4 56.1

2.5

3.8

0.9

2.0

480

20.1 13.0 0.92 21.9 23.2 82.4

1.8

3.8

0.9

2.0

480

22.1 1.30

5.0

17.6 112.6 60.6

2.8

3.8

0.9

2.0

600

20.5 14.2 0.96 21.4 23.8 82.7

1.8

3.8

0.9

2.0

600

22.6 1.26

5.2

18.3 104.8 60.3

2.7

5.0

1.6

3.6

480

20.4 13.1 0.88 23.2 23.4 79.4

1.6

5.0

1.6

3.6

480

22.5 1.31

5.0

18.1 113.5 62.8

2.8

5.0

1.6

3.6

600

20.8 14.3 0.92 22.6 24.0 79.6

1.6

5.0

1.6

3.6

600

23.0 1.27

5.3

18.7 105.5 62.5

2.7

80

2.5

0.3

0.6

480

18.3 12.3 1.18 15.6 22.3 97.9

2.9

2.5

0.3

0.6

480

22.9 1.32

5.1

18.4 114.3 65.3

2.9

2.5

0.3

0.6

600

18.7 13.4 1.23 15.2 22.9 98.3

3.0

2.5

0.3

0.6

600

23.4 1.28

5.4

19.1 106.2 64.8

2.8

3.8

0.8

1.9

480

19.1 12.5 1.07 17.8 22.7 92.1

2.4

3.8

0.8

1.9

480

23.7 1.35

5.2

19.1 115.7 69.8

3.1

3.8

0.8

1.9

600

19.4 13.7 1.12 17.4 23.3 92.4

2.5

3.8

0.8

1.9

600

24.2 1.30

5.5

19.7 107.3 69.5

3.0

5.0

1.5

3.4

480

19.1 12.6 1.06 18.0 22.7 89.1

2.1

4.0

0.9

2.1

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

5.0

1.5

3.4

600

19.5 13.7 1.11 17.6 23.3 91.8

2.2

4.0

0.9

2.1

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

90

2.5

0.3

0.7

480

17.1 11.8 1.36 12.6 21.7 107.4

3.9

2.0

0.2

0.5

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

2.5

0.3

0.7

600

18.2 13.2 1.30 14.0 22.7 107.8 3.4

2.0

0.2

0.5

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

3.8

0.8

1.9

480

17.9 12.1 1.24 14.4 22.1 101.8

3.3

2.0

0.2

0.5

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

3.8

0.8

1.9

600

18.2 13.2 1.30 14.0 22.7 102.1 3.4

2.0

0.2

0.5

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

5.0

1.4

3.3

480

18.2 12.2 1.18 15.4 22.3 98.9

3.0

2.0

0.2

0.5

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

5.0

1.4

3.3

600

18.6 13.3 1.24 15.0 22.8 99.1

3.1

2.0

0.2

0.5

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

100

2.5

0.3

0.7

480

15.7 11.4 1.57 10.0 21.0 116.8 5.1

1.3

0.2

0.5

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

2.5

0.3

0.7

600

16.0 12.4 1.64

9.7

21.6 117.3 5.2

1.3

0.2

0.5

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

3.8

0.8

1.9

480

16.5 11.6 1.44 11.4 21.4 111.4 4.3

1.3

0.2

0.5

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

3.8

0.8

1.9

600

16.9 12.7 1.51 11.2 22.0 111.7 4.4

1.3

0.2

0.5

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

5.0

1.4

3.2

480

16.9 11.8 1.39 12.2 21.7 108.7 4.0

1.3

0.2

0.5

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

5.0

1.4

3.2

600

17.3 12.8 1.45 11.9 22.2 108.9 4.1

1.3

0.2

0.5

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

110

2.5

0.3

0.6

480

14.1 10.9 1.81

7.8

20.3 126.2 6.3

1.0

0.1

0.2

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

2.5

0.3

0.6

600

14.4 11.9 1.89

7.6

20.8 126.7 6.5

1.0

0.1

0.2

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

3.8

0.8

1.8

480

15.0 11.2 1.67

9.0

20.7 121.0 5.6

1.0

0.1

0.2

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

3.8

0.8

1.8

600

15.3 12.2 1.75

8.7

21.3 121.3 5.7

1.0

0.1

0.2

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

5.0

1.4

3.1

480

15.5 11.3 1.60

9.6

20.9 118.4 5.2

1.0

0.1

0.2

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

5.0

1.4

3.1

600

15.8 12.3 1.68

9.4

21.5 118.6 5.3

1.0

0.1

0.2

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

120

2.5

0.1

0.3

480

12.4 10.3 2.06

6.0

19.4 135.5 7.8

0.8

0.1

0.2

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

2.5

0.1

0.3

600

12.6 11.3 2.16

5.8

20.0 136.0 8.0

0.8

0.1

0.2

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

3.8

0.7

1.5

480

13.3 10.6 1.92

6.9

19.9 130.6 7.0

0.8

0.1

0.2

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

3.8

0.7

1.5

600

13.6 11.6 2.01

6.8

20.5 130.9 7.2

0.8

0.1

0.2

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

5.0

1.3

2.9

480

13.8 10.8 1.85

7.5

20.1 128.1 6.6

0.8

0.1

0.2

480

23.7 1.35

5.2

19.2 115.8 70.0

3.1

5.0

1.3

2.9

600

14.1 11.8 1.94

7.3

20.7 128.3 6.8

0.8

0.1

0.2

600

24.2 1.30

5.5

19.8 107.4 70.0

3.0

Interpolation is permissible; extrapolation is not. All performance is based upon the lower voltage of dual voltage rated units.

Flow is controlled to maintain minimum LWT 70° F in cooling and maximum LWT 65° F in heating.

Operation at or below 40° F EWT is based on 15% methanol antifreeze solution. Table does not reflect fan or pump power corrections for AHRI/ISO conditions.

See Performance correction tables for operating conditions other than those listed above.