6

G e o t h e r m a l H e a t i n g a n d Co o l i n g

Tranquility

®

22 Digital (TZ

)

Series - 60Hz

R e v. : N o v e m b e r 1 8 , 2 0 2 2

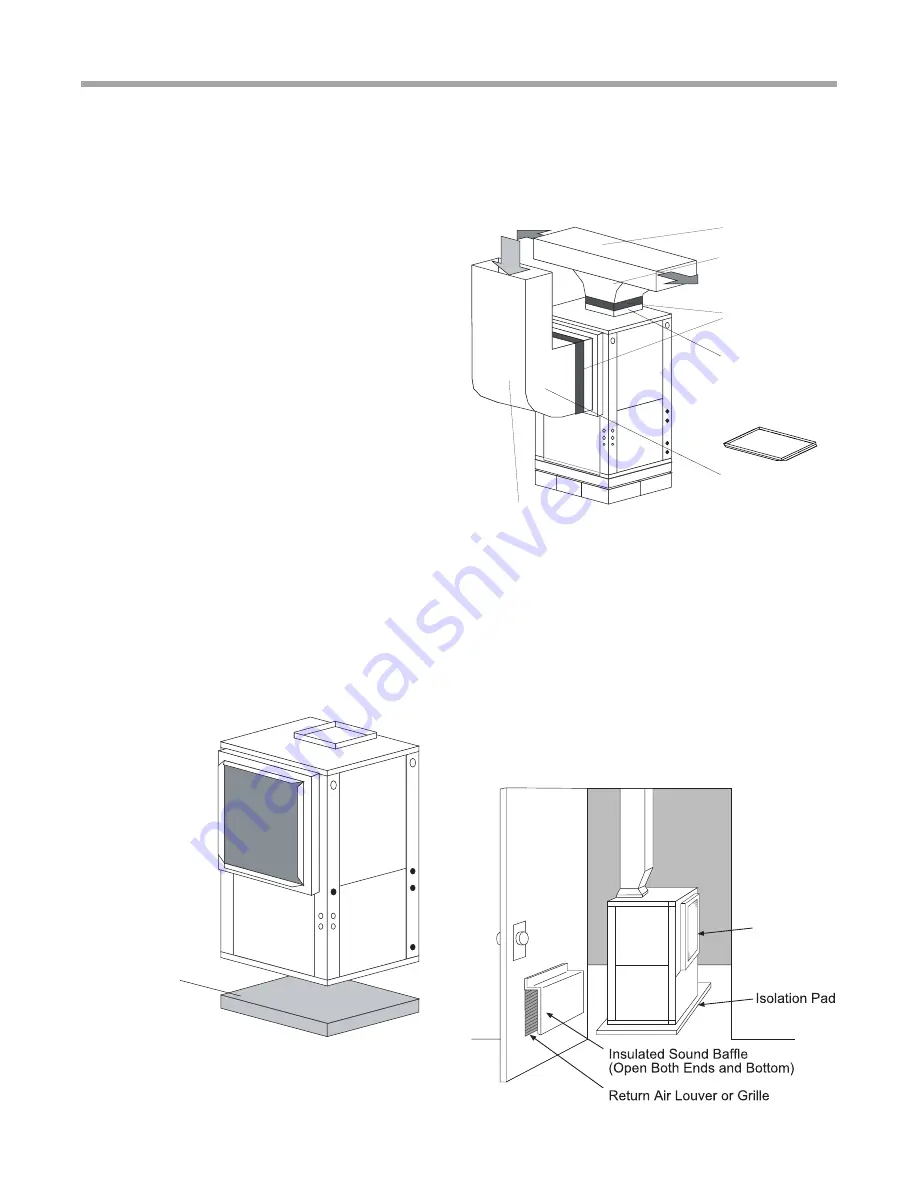

Vertical Installation

VERTICAL UNIT LOCATION

Packaged units are not designed for outdoor installation.

Locate the unit in an INDOOR area that allows enough space

for service personnel to perform typical maintenance or

repairs without removing the unit from the installed location.

Vertical units are typically installed in a mechanical closet

or basement. Never install units in areas subject to freezing

or where humidity levels could cause cabinet condensation

(such as unconditioned spaces subject to 100% outside air).

Also, provide sufficient room to make water, electrical, and

duct connection(s).

If the unit is located in a confined space, such as a closet,

provisions must be made for return air to freely enter the

space by means of a louvered door or other method. Any

access panel screws that would be difficult to remove after

the unit is installed should be removed prior to setting

the unit. Refer to Figures 1 and 2 for typical installation

illustrations. Refer to unit catalog specifications for

dimensional data.

1. Install the unit on a piece of rubber, neoprene or other

mounting pad material for sound isolation. The pad

should be at least 3/8 inches [10 mm] to 1/2 inches

[13 mm] in thickness. Extend the pad beyond all four

edges of the unit.

2.

Do not block filter access with piping, conduit or other

materials. Refer to unit catalog specifications for

dimensional data.

3.

Provide access to water valves and fittings and

screwdriver access to the unit side panels, discharge

collar and all electrical connections.

Figure 1: Vertical Unit Mounting

bloque o del ladrillo o sacado

Cojín del aire o sacado

Bloque o ladrillo concreto

Air Pad or extruded

polystyrene insulation board

Figure 2: Typical Vertical Unit Installation Using

Ducted Return Air

Flexible canvas duct

connector to reduce

noise and vibration

Use turning vanes in

supply transition

Internally insulate supply

duct for first 3.9 feet (1.2 m)

each way to reduce noise

Internally insulate return

transition duct to reduce

noise

Rounded return

transition

Flexible canvas duct

connector to reduce

noise and vibration

Use turning vanes in

supply transition

Internally insulate return

transition duct to reduce

noise

Rev.: 6/2/09S

Internally insulate supply

duct for the first 4’ (1.2m)

each way to reduce noise

Rounded return

transition

Remove supply duct

flanges from inside blower

compartment and install

on supply air opening of

unit. Do not use a supply

air plenum/duct smaller

than the size of the supply

duct flanges.

Remove supply duct

flanges from inside blower

compartment and install

on supply air opening of

unit. Do not use a supply

air plenum/duct smaller

than the size of the supply

duct flanges.

SOUND ATTENUATION FOR VERTICAL UNITS

Sound attenuation is achieved by enclosing the unit within a

small mechanical room or a closet. Additional measures for

sound control include the following:

1. If free return, mount the unit so that the return air inlet

is 90° to the return air grille (refer to Figure 3). Install a

sound baffle as illustrated to reduce line-of sight sound

transmitted through return air grilles.

2. Mount the unit on a Tranquility

®

Unit Isolation Pad to

minimize vibration transmission to the building structure.

For more information on Tranquility Unit Isolation Pads,

contact your distributor.

Figure 3: Vertical Sound Attenuation

Return

Air Inlet