7

c l i m a t e m a s t e r.c o m

Tranquility

®

22 Digital (TZ

)

Series - 60Hz

R e v. : N o v e m b e r 1 8 , 2 0 2 2

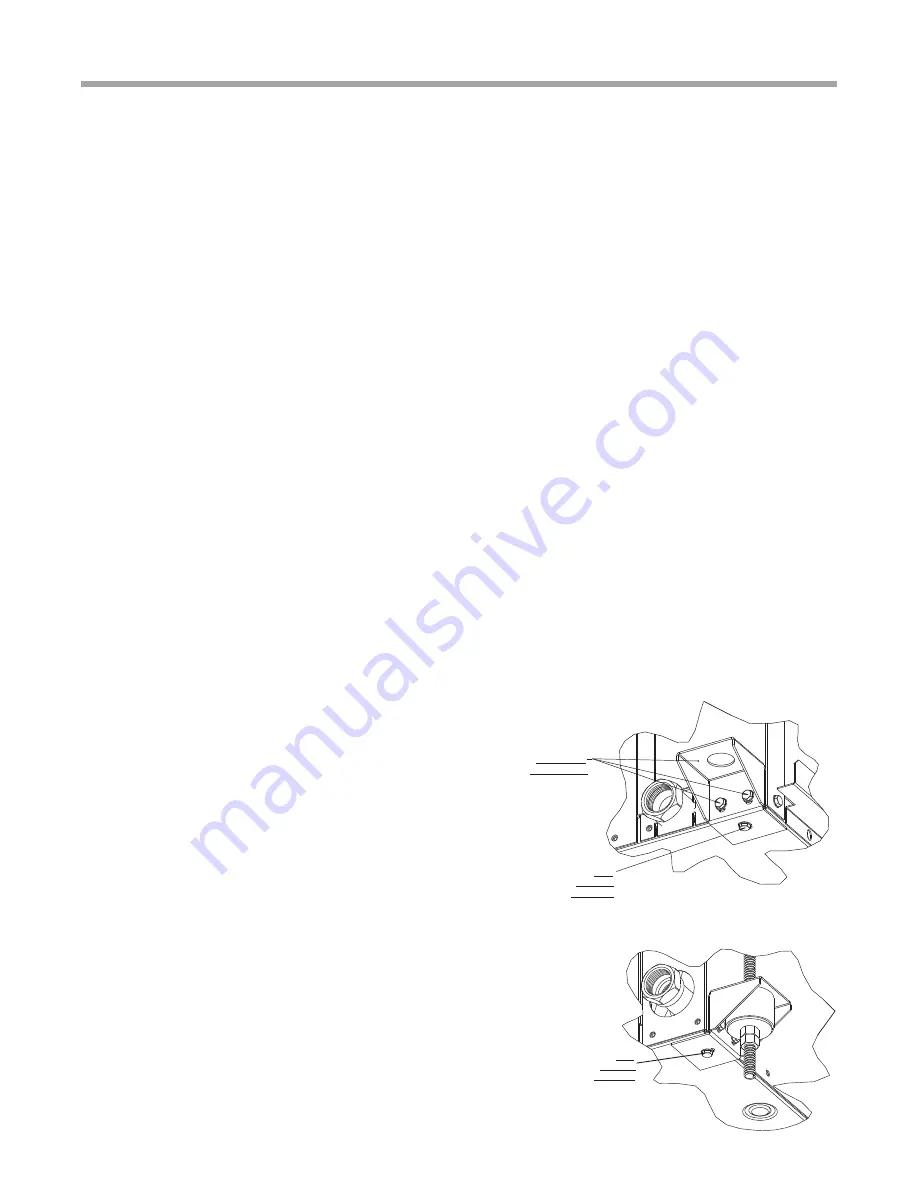

Horizontal Installation

Figure 4: Hanger Bracket

HORIZONTAL UNIT LOCATION

Packaged units are not designed for outdoor installation.

Locate the unit in an INDOOR area that allows enough space

for service personnel to perform typical maintenance or

repairs without removing unit from the ceiling. Horizontal

units are typically installed above a false ceiling or in a ceiling

plenum. Never install units in areas subject to freezing or

where humidity levels could cause cabinet condensation

(such as unconditioned spaces subject to 100% outside air).

Consideration should be given to access for easy removal of

the filter and access panels. Provide sufficient room to make

water, electrical, and duct connection(s).

If the unit is located in a confined space, such as a closet,

provisions must be made for return air to freely enter the

space by means of a louvered door or any other method.

Any access panel screws that would be difficult to remove

after the unit is installed should be removed prior to setting

the unit. Refer to Figures 7a and 7b for an illustration of a

typical installation. Refer to unit catalog specifications for

dimensional data.

Conform to the following guidelines when selecting a

unit location:

1. Provide a hinged access door in concealed-spline or

plaster ceilings. Provide removable ceiling tiles in T-bar

or lay-in ceilings. Refer to horizontal unit dimensions for

specific series and model in unit catalog specifications.

Size the access opening to accommodate the service

technician during the removal or replacement of the

compressor, control, or blower assembly.

2. Provide access to hanger brackets, water valves and

fittings. Provide screwdriver clearance to access panels,

discharge collars and all electrical connections.

3. DO NOT obstruct the space beneath the unit with

piping, electrical cables and other items that prohibit

future removal of components or the unit itself.

4. Use a manual portable jack/lift to lift and support the

weight of the unit during installation and servicing.

MOUNTING HORIZONTAL UNITS

Horizontal units have 4 hanger brackets partially attached

at the factory, one at each corner. Enclosed within the unit

there is a hanger kit hardware bag containing vibration

isolation grommets, washers, screws and a hanger installation

instruction page. One additional screw from the hardware bag

must be added to each hanger bracket before unit installation.

Tighten each screw to 75 in-lbs (8.5 Nm). See Figure 1. Refer

to the hanger installation instruction page contained in the

hardware bag for details of final hanger bracket attachment

and unit suspension. See Figure 1a.

Use four (4) field supplied threaded rods and factory provided

vibration isolators to suspend the unit. Safely lift the unit into

position supporting the bottom of the unit. Ensure the top of

the unit is not in contact with any external objects. Connect

the top end of the 4 all-thread rods, slide rods through the

brackets and grommet then assemble washers and double

nuts at each rod. Ensure that the unit is approximately level

and that the threaded rod extends past the nuts.

Pitch the unit toward the drain as shown in Figure 6 to

improve the condensate drainage. On small units (less than

2.5 Tons/8.8 kW) ensure that unit pitch does not cause

condensate leaks inside the cabinet.

NOTE: The top panel of a horizontal unit is a structural

component. The top panel of a horizontal unit must never

be removed from an installed unit unless the unit is properly

supported from the bottom. Otherwise, damage to the unit

cabinet may occur.

VIEW CONDENSATE END

BEFORE GROMMET AND HARDWARE

(Unit pictured for hanger bracket reference).

(Drain hardware may vary per unit model)

INSTALLED

AT FACTORY

ADD

BEFORE

HANGING

Figure 4a:

VIEW WATER CONNECTION END

FULLY ASSEMBLED

(Unit pictured for hanger bracket reference)

(Water hardware may vary per unit model)

ADD

BEFORE

HANGING