11

Subject to Technical Modifications of GV-HR110

Condensation drain:

When it is time to exchange the filter in the fall, check the

condensation drain for fouling by dirt and make sure there

is water in the waterseal. The waterseal must not dry out

since the negative pressure of the aggregate will suck air

into the aggregate causing the condensation to remain in

the aggregate. Pour 1 litre of water into the condensation

container and check that the flow is undeterred. If the

condensation drain does not work correctly water damages

may occur in the residence.

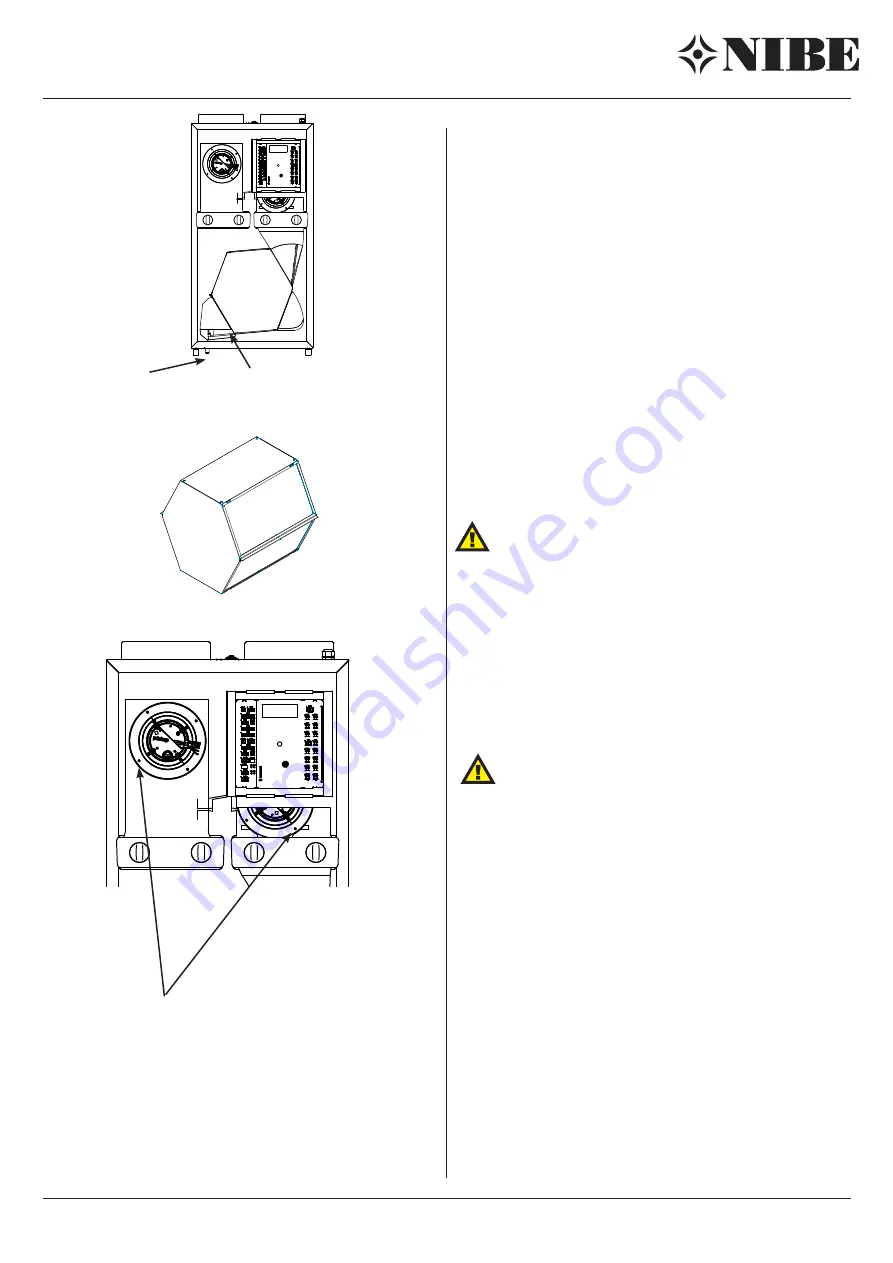

Counter-flow heat exchanger

The counter-flow heat exchanger must be overseen

every year. Remove it if it is dirty and vacuum it without

touching the plates. Open the front of the condensation

container before removing the counter-flow heat

exchanger. This is done by opening the spring latch on

the right corner of the condensation container. Push

lightly from behind when removing the counter-flow heat

exchanger.

Do not damage the plates. The effect will no

longer be optimal if the plates are damaged.

Fans:

Remember to switch of the power supply!!

Check the fans in the fan wheel for dirt every third year.

The four outermost screws that hold the fans in place

must be removed in order to remove the fans. Remove

the front lid of the unit. Clean the fans using a brush, fan

brush or paintbrush.

The filter units must be removed

before disassembling the front lid.

Incoming and outgoing units:

The ventilation unit must be cleaned regularly with a small

brush in order to maintain correct ventilation. Do not

change the setting. N.B. Do not mix the units up when

many are cleaned at the same time.

12: Kondensvandsafløb

11: Kondensvandsbakke

9. Udsugningsfilter

7: Udsugningsventilator

6: Indblæsningsventilator

5: Modstrømsvarmeveksler

14: By-pass

13: 230V/50Hz

10: El-kasse

8: Friskluftfilter

4: Indblæsning

3: Udsugning

2: Afkast

1: Frisk luft

3

1

4

2

13

265

128.6

550

280

135

550

24

32

60.7

1014

42

1056

1088

The four outermost screws that hold the fans in

place must be removed in order to remove the

fans.

12: Kondensvandsafløb

11: Kondensvandsbakke

9. Udsugningsfilter

7: Udsugningsventilator

6: Indblæsningsventilator

5: Modstrømsvarmeveksler

14: By-pass

13: 230V/50Hz

10: El-kasse

8: Friskluftfilter

4: Indblæsning

3: Udsugning

2: Afkast

1: Frisk luft

3

1

4

2

13

265

128.6

550

280

135

550

24

32

60.7

1014

42

1056

1088

Condensation drain

Counter-flow

heat exchanger

Spring latch,

condensation container