MEL 1030, 0040, 1060, 1090, 2090, 2120

22

Installa on and Opera on Manual

The electrical module you have bought is designed for hea ng domes c hot water and central hea ng water. It can be in-

stalled in each tank (apart from stainless steel ones) the structure of which (construc on and size) makes it possible. Before

installa on:

•

Read this Installa on and Opera on Manual carefully.

• Entrust

installa on of the hea ng module to a quali

fi

ed person holding appropriate electrical rights.

•

The electrical wiring system must be made according to binding regula ons.

• Before

star ng the device, ensure all the connec ons are correct and ght.

•

Provide proper opera ng condi ons, according to the device technical speci

fi

ca on.

•

To avoid actua on of temperature limit fuse, limit the temperature of hea ng water supplied to the heat exchanger

down to 80°C.

•

Check the tank technical speci

fi

ca on. For BIAWAR tanks, select the hea ng module according to Table 2. The tank

structure should allow for collision-free installa on of the hea ng element inside.

Check the connector pipe diameter – it should correspond with the hea ng module thread size.

•

Check the connector pipe length: it must be longer than the hea ng module dead zone.

•

Check the material of which the tank is made. The module must not be installed in the stainless-steel tanks.

3. Installa on requirements

4. Loca on and installa on

The electrical module can be installed only horizontally, both in horizontal and in ver cal tanks whose structure allows for

installa on of an electrical module of parameters according to the TECHNICAL DATA table, as well as other requirements

included in the instruc ons below.

The module must not be used in the stainless-steel tanks

CAUTION

The hea ng module must not be installed in the rooms where ambient temperature falls below 5°C or grow up above

50°C.

CAUTION

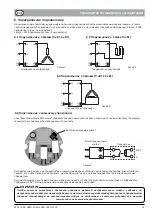

5. The hea ng module installa on

1. If the module is installed into an already-working device, drain water

fi

rst.

2. Unscrew the plug protec ng the connector pipe. Screw-in the electrical module instead of the plug

(Fig. 1 posi on 1) – seal the thread with oakum or other sealing means available.

3. Screw-in the module so that the supply hose plug is directed down. The module opera on in a di

ff

erent posi on is

forbidden.

4. Fill-up the tank, vent the pipe system and then check ghtness of the hydraulic connec on at the module

installa on point.

5. If there connec on is not ght, drain the tank, seal the connec on once again and repeat the opera ons of sec. 2-4.

6. Unscrew the box front side (Fig. 1 posi on 2),

7. Connect power supply cables to appropriate terminals located in the upper part of the box (posi on 2) according to

the

connec on diagram for three-phase or single-phase heaters (see electrical connec on diagram).

8. Make the electrical connec on according to the electrical diagram.

9. Mount the upper part of the box onto the rest of the hea ng assembly.

10.

Using

bu ons, set the required water temperature, see: ACTIVATION AND OPERATION p. 25

GB